Continuous production process of PE breathable film composite fabric

A production process and technology of composite fabrics, applied in applications, household appliances, flat products, etc., can solve the problems of increasing PE production costs, unfavorable enterprise production needs, fabric unit price growth, etc., to increase production profits, reduce packaging processing steps, Process tight rhythm effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

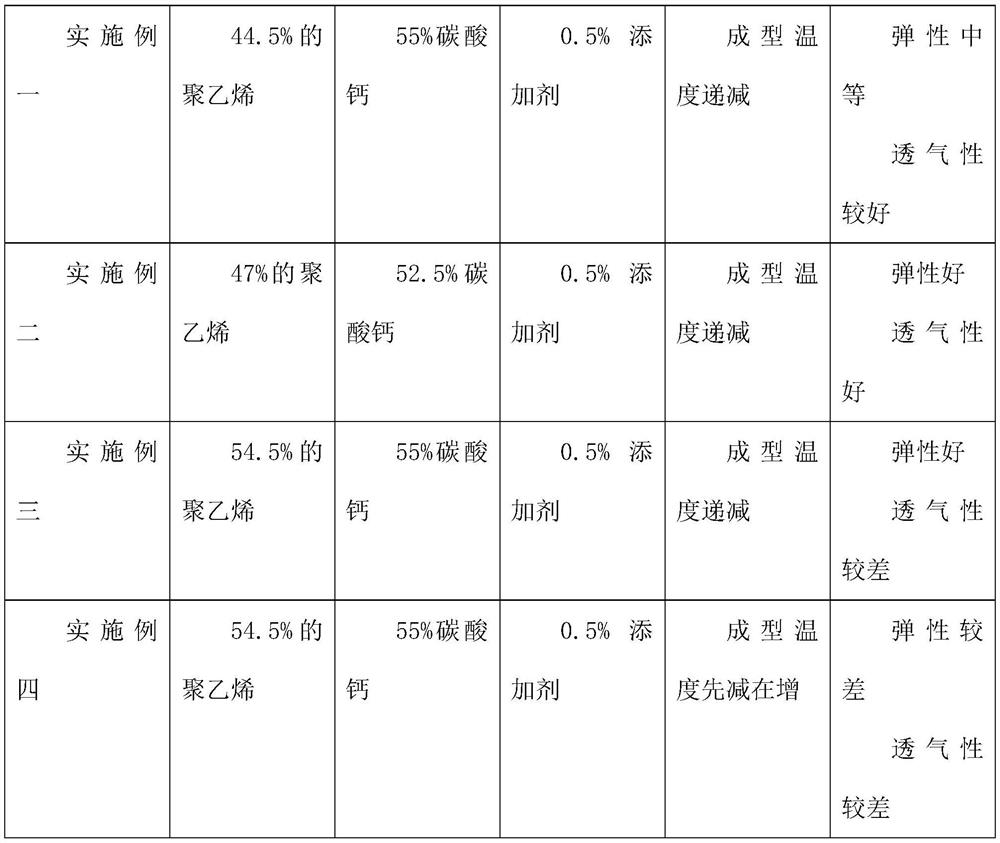

Embodiment 1

[0029] The embodiment of the present invention provides a continuous production process of PE breathable film composite fabric, including the weight percentage of raw materials used: 44.5% polyethylene; 55% calcium carbonate: 0.5% additive.

[0030] The treatment process of the continuous production process is:

[0031] Step 1: Put polyethylene, calcium carbonate and additives into the stirring device for full and uniform stirring;

[0032] Step 2: Then put the mixed material into the kneader for heating, kneading, plasticizing, melting, filtering, and pelletizing;

[0033] Step 3: Dry and dehumidify the pelletized material;

[0034] Step 4: heating and melting the dried and dehumidified granular materials;

[0035] Step 5: Then send it to the mold for extrusion into a base film;

[0036] Step 6: Bond the high elastic fabric on both sides of the extruded base film:

[0037] Step 7: Then preheat and stretch the composite film.

[0038] The additives include lubricants, ant...

Embodiment 2

[0040] The embodiment of the present invention provides a continuous production process of PE breathable film composite fabric, including the weight percentage of raw materials used: 47% polyethylene; 52.5% calcium carbonate: 0.5% additive.

[0041] The treatment process of the continuous production process is;

[0042] Step 1: Put polyethylene, calcium carbonate and additives into the stirring device for full and uniform stirring;

[0043] Step 2: Then put the mixed material into the kneader for heating, kneading, plasticizing, melting, filtering, and pelletizing;

[0044] Step 3: Dry and dehumidify the pelletized material;

[0045] Step 4: heating and melting the dried and dehumidified granular materials;

[0046] Step 5: Then send it to the mold for extrusion into a base film;

[0047] Step 6: Then preheat and stretch the composite film.

[0048] The additives include lubricants, antioxidants and fragrances, the weight ratio of each component is 1:1:0.6, the heating tem...

Embodiment 3

[0050] The embodiment of the present invention provides a continuous production process of PE breathable film composite fabric, including the weight percentage of raw materials used: 54.5% polyethylene; 45% calcium carbonate: 0.5% additive.

[0051] The treatment process of the continuous production process is;

[0052] Step 1: Put polyethylene, calcium carbonate and additives into the stirring device for full and uniform stirring;

[0053] Step 2: Then put the mixed material into the kneader for heating, kneading, plasticizing, melting, filtering, and pelletizing;

[0054] Step 3: Dry and dehumidify the pelletized material;

[0055] Step 4: heating and melting the dried and dehumidified granular materials;

[0056] Step 5: Then send it to the mold for extrusion into a base film;

[0057] Step 6: Bond the high elastic fabric on both sides of the extruded base film:

[0058] Step 7: Then preheat and stretch the composite film.

[0059] The additives include lubricants, ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com