Multi-process combination machine tool for crankshaft machining

A combined machine tool and crankshaft processing technology, used in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of easy scratching, low precision, easy bumping of the crankshaft, etc., and improve the quality of hot pressing assembly. , the processing rhythm is compact, the effect of shortening the work rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

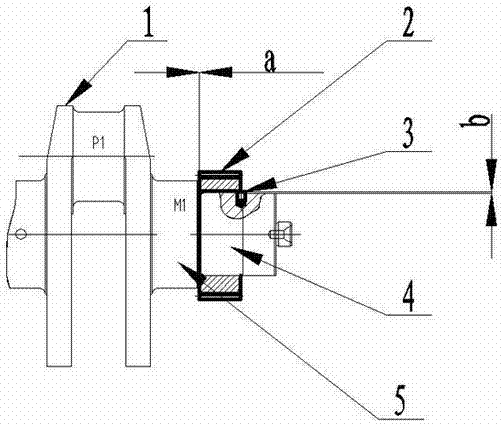

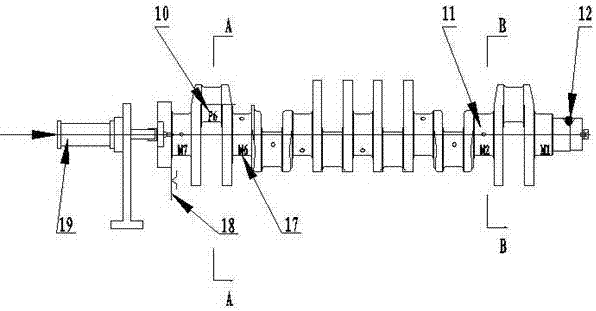

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the pin 3 is press-fitted into the pin hole 12 on the gear journal 4 of the crankshaft 1 with an interference fit. , The inner hole keyway on the gear 2 is aligned with the pin 3 and installed on the gear journal 4 by hot pressing, and the gap between it and the end surface of the M1 main journal 5 is a.

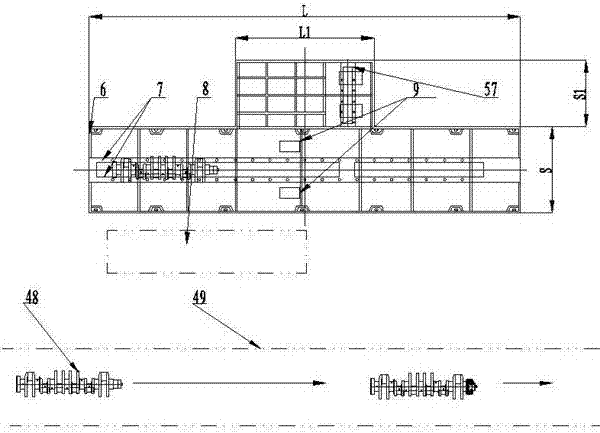

[0041]In order to realize the above-mentioned assembly, when designing the combined machine tool bed, the present invention concentrates and combines all processing components around the bed 36 . The fuselage is designed as a L×S rectangular structure. All processing parts can be placed in the L length direction, and the S width direction can ensure all positioning and clamping tooling positions of the crankshaft 48 to be processed and reserve chip removal holes 9 . Since the Z540 drilling machining center 47 and the pressing pin table 25 need to be placed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com