Rudder for watercraft, and method and device for measurement of bearing clearance in a rudder

A bearing clearance and watercraft technology, applied in the rudder field of watercraft, can solve the problems of bearing bush wear, rudder system failure, rudder damage, etc., and achieve the effect of continuous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

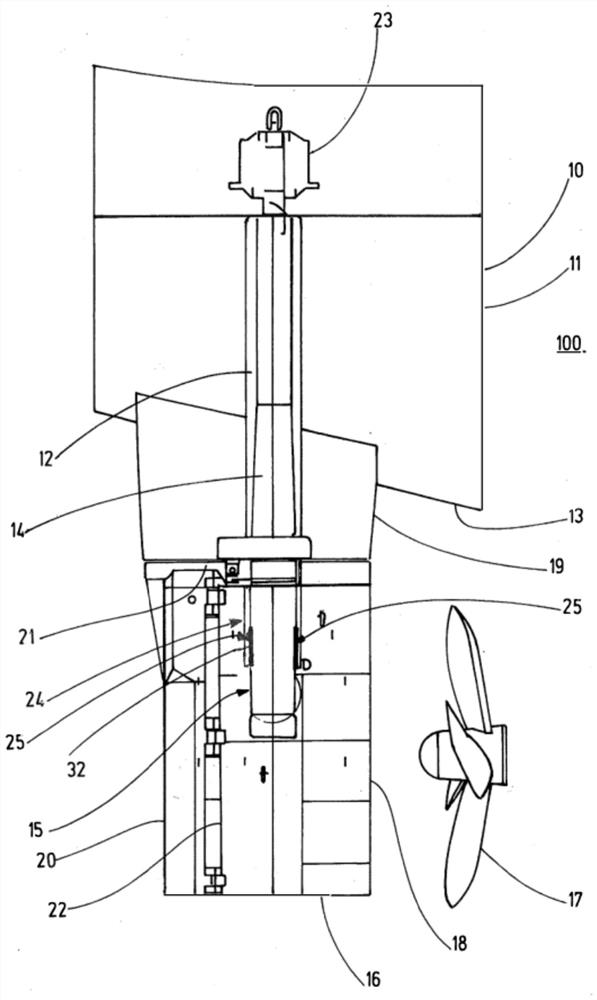

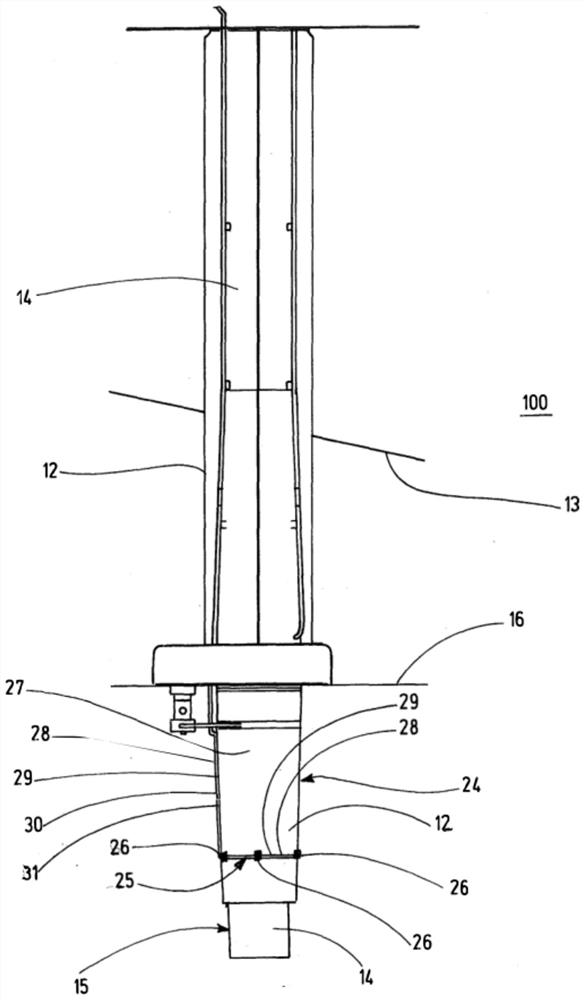

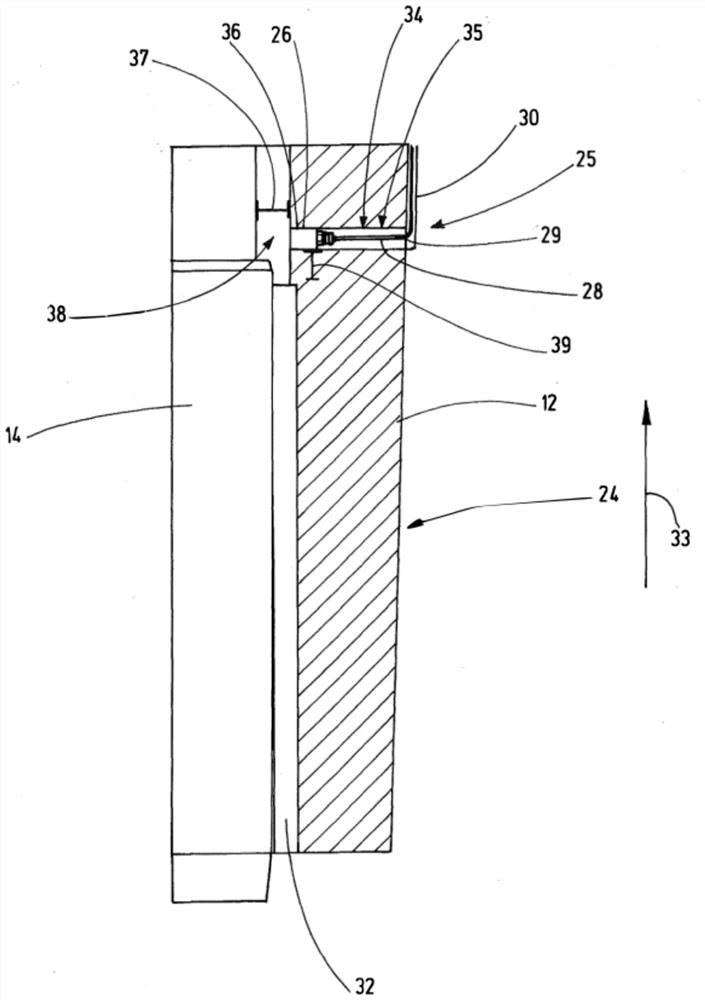

[0105] figure 1 shown only in figure 1 A rudder 100 on a watercraft 10 is shown in cross-section. The watercraft 10 is configured as a watercraft 11 . The rudder 100 comprises a main pipe 12 fastened in a fixed manner into the hull 13 of the vessel 11 . A rudder shaft 14 is rotatably arranged in the main pipe 12 . The rudder blade 16 of the rudder 100 is fastened to the lower end 15 of the rudder shaft 14 . The rudder blade 16 is arranged behind the propeller 17 of the vessel 11 . The leading edge 18 of the rudder blade 16 faces the propeller 17 . Furthermore, a skeg 19 is arranged on the hull 13 , through which the main pipe 12 and the rudder shaft 14 are guided. The lower end 15 of the rudder shaft 14 projects into the rudder blade 16 . The rudder blade 16 also has a hinged vane 20 which is pivotably arranged on an end plate 22 of the rudder blade 16 via a connecting device 21 . The rudder blade 16 and the rudder shaft 14 are connected to a rudder system 23 in the hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com