Low-magnesium barium-containing spheroidized cored wire

A cored wire, low magnesium technology, used in the field of ferrous metal materials, can solve the problems of short wire feeding time, casting pores, and unstable residual Mg in molten iron, and achieve low spheroidization, reduced magnesium content, and low porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

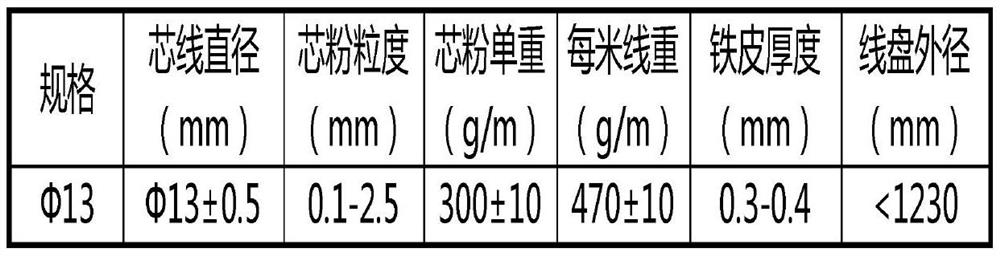

Embodiment 1

[0021] A low-magnesium barium-containing spheroidized cored wire, made of core powder coated with steel skin, including the composition and mass percentage of the core powder: Mg: 8%, Si: 45%, RE: 1.5%, Ba: 5%, Ca: 1.5%, MgO: 0.5%, Al: 1.0%, and the balance is Fe. The core powder is melted and mixed with Mg, Si, RE, Ba, Ca, MgO, Al and Fe according to the technical requirements, and crushed into pellets by a granulator, and sieved by a vibrating sieve to a particle size of 0.1-2.5mm , core powder particle weight 290 ~ 310g / m3, complete core powder preparation. The core powder and steel strip are prepared by the cored wire machine according to the technical production requirements, and then fed into the molten iron by the wire feeding machine. The wire feeding time is 24s, and the bottom of the cored wire is processed to prepare the core diameter of Φ13㎜ spheroidized cored wire.

Embodiment 2

[0023] A low-magnesium barium-containing spheroidized cored wire, made of core powder coated with steel skin, including the composition and mass percentage of the core powder: Mg: 9%, Si: 46%, RE: 1.8%, Ba: 6%, Ca: 1.8%, MgO: 0.8%, Al: 1.1%, and the balance is Fe. The core powder is melted and mixed with Mg, Si, RE, Ba, Ca, MgO, Al and Fe according to the technical requirements, and crushed into pellets by a granulator, and sieved by a vibrating sieve to a particle size of 0.1-2.5mm , core powder particle weight 290 ~ 310g / m3, complete core powder preparation. The core powder and steel strip are prepared by the cored wire machine according to the technical production requirements, and then fed into the molten iron by the wire feeding machine. The wire feeding time is 26s, and the bottom of the cored wire is processed to prepare the core diameter of Φ13㎜ spheroidized cored wire.

Embodiment 3

[0025] A low-magnesium barium-containing spheroidized cored wire, made of core powder coated with steel skin, including the composition and mass percentage of the core powder: Mg: 10%, Si: 47%, RE: 1.9%, Ba: 7%, Ca: 2%, MgO: 0.9%, Al: 1.2%, and the balance is Fe. The core powder is melted and mixed with Mg, Si, RE, Ba, Ca, MgO, Al and Fe according to the technical requirements, and crushed into pellets by a granulator, and sieved by a vibrating sieve to a particle size of 0.1-2.5mm , core powder particle weight 290 ~ 310g / m3, complete core powder preparation. The core powder and steel strip are prepared by the cored wire machine according to the technical production requirements, and then fed into the molten iron by the wire feeding machine. The wire feeding time is 28s, and the bottom of the cored wire is processed, and the diameter of the prepared wire core is Φ13㎜ spheroidized cored wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com