Anti-upwarp threaded pile structure and design and construction method thereof

A technology of construction method and design method, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of poor economy, limited pile side resistance, high economy, etc., so as to increase the anti-arching ability and enhance the uplift resistance Performance, the effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

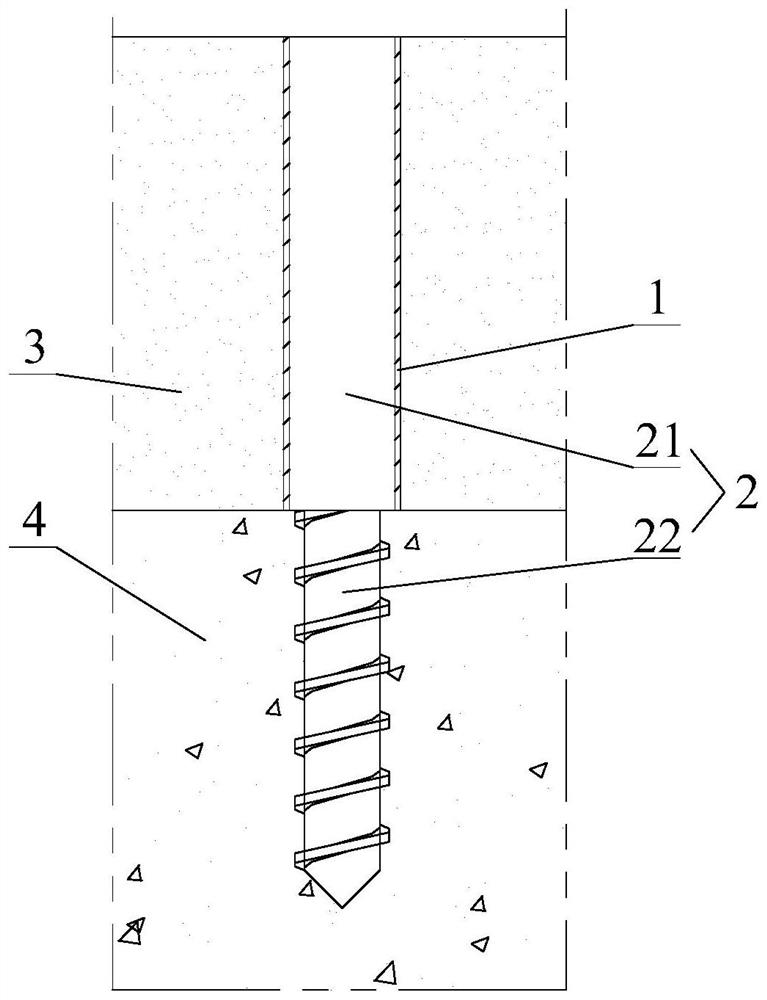

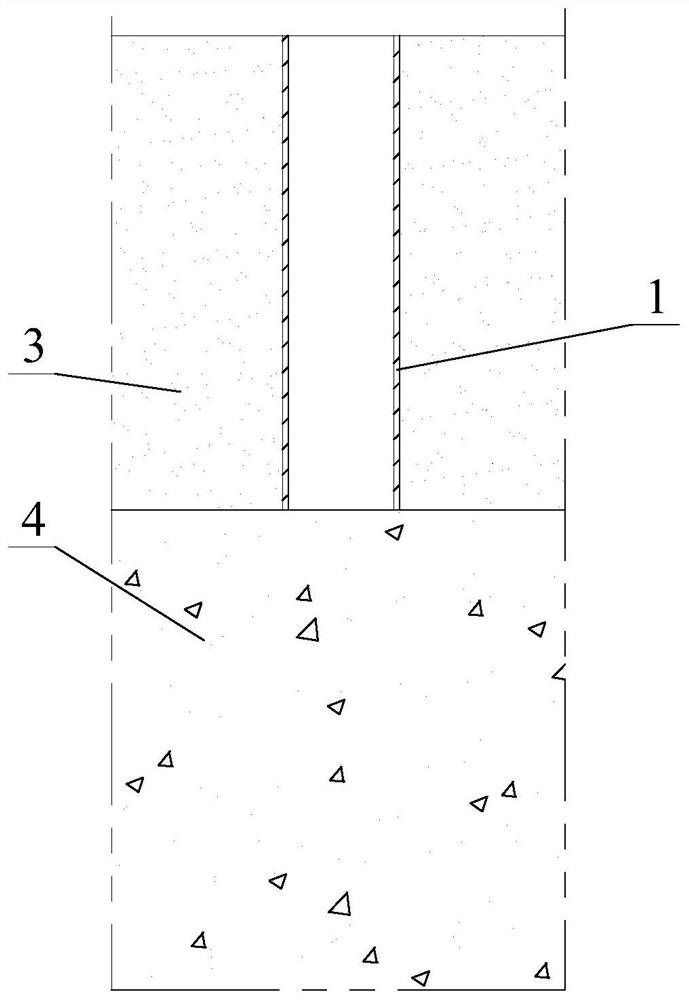

[0053] Such as figure 2 As shown, the anti-arching threaded pile structure described in this embodiment includes a threaded pile 2, the upper part of the threaded pile 2 has a section 21 of equal diameter, and the lower part of the threaded pile 2 has a threaded section 22. There are threads on the outer wall of the threaded section 22, and the outside of the equal-diameter section 21 is covered with a double-layer steel casing 1. The double-layer steel casing 1 includes an inner steel casing and an outer steel casing, and the inner steel casing It can move relative to the outer steel casing. During construction, the threaded section 22 extends into the stable zone 4 of the foundation, and the equal-diameter section 21 is located in the upper arch deformation zone 3 of the foundation. The threaded pile 2 outside the equal-diameter section 21 There is a double-layer steel casing 1, which can effectively eliminate the adverse side resistance effect of the threaded pile 2 struct...

Embodiment 2

[0057] Such as figure 2 As shown, a design method for the anti-arching threaded pile structure described in Embodiment 1 described in this embodiment includes the following steps,

[0058] 1. Calculate the area of the threaded pile 2 according to the outer diameter of the threaded pile 2:

[0059] A p = πD 2 / 4

[0060] In the formula: A p is the area of threaded pile 2, m2; D is the outer diameter of threaded pile 2, m.

[0061] 2. Calculate the circumference of the threaded pile 2 according to the outer diameter of the threaded pile 2:

[0062] u=πD

[0063] In the formula: u is the circumference of threaded pile 2, m.

[0064] 3. Calculate the effective self-weight of threaded pile 2:

[0065] G p =γA p l p

[0066] In the formula: G p is the self-weight of the threaded pile 2, kN; λ is the average weight of the soil between the threaded pile 2 and the thread, which can be approximated as the concrete weight, and the buoyant weight below the groundwater le...

Embodiment 3

[0080] Such as figure 2 As shown in the figure, the soft rock deep cutting structure of a ballastless track of a high-speed railway is provided with threaded pile structures to resist the upward arching force generated by the soft rock. Screw pile length l p The length of the threaded pile is 15m, the length l of the threaded pile is 5m, the outer diameter of the threaded pile is D=1.2m, the inner diameter is d=1.0m, and the concrete weight is 25kN / m 3 , without considering the effect of groundwater. The pullout coefficient λ of the threaded pile is 0.7, the enhancement coefficient β is 1.5, the stratum below the base is uniform, and the standard value of the ultimate side resistance of the dry-work bored pile in soft rock is q sik is 80kPa. The safety factor K is taken as 2.0, and the vertical uplift bearing capacity of threaded pile 2 single pile required on site must be greater than 1100KN.

[0081] (1) Calculate the area of the threaded pile according to the outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com