Graphite metal reinforced gasket suitable for inner and outer dual layer seal and method

A metal-reinforced, inner-outer double-layer technology, applied in metal processing equipment, engine seals, grinding machines, etc., can solve problems such as poor self-tightening ability, difficult measurement, partial ring body seal failure, etc., to reduce the probability of seal failure, The effect of reducing the workload of manpower and enhancing the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technology of the present invention is further described below:

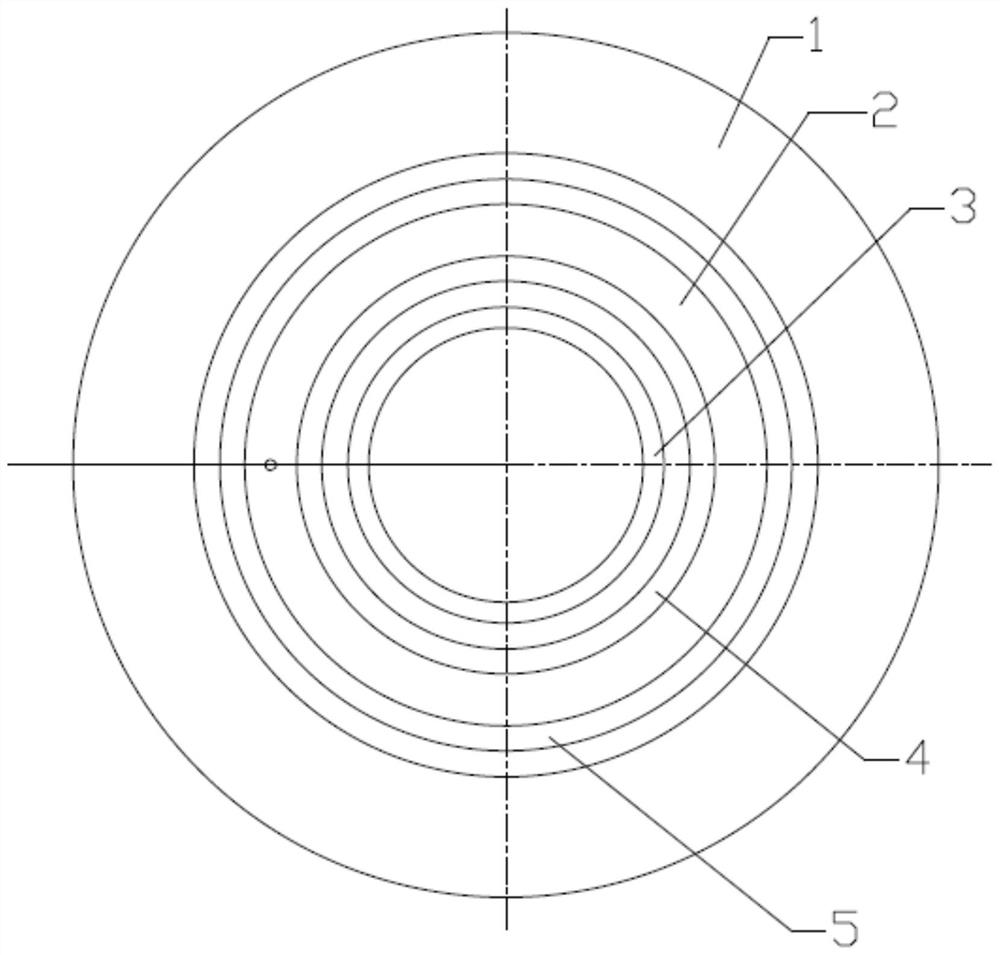

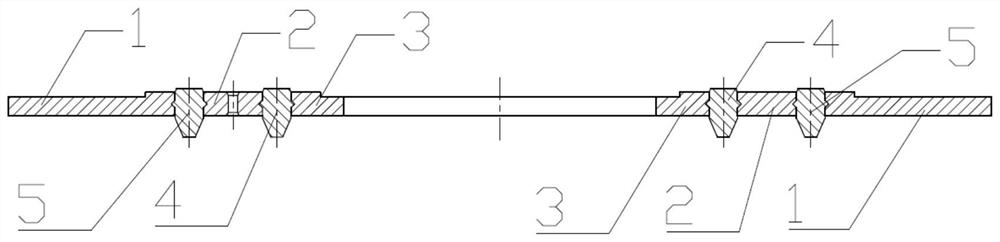

[0037] Such as figure 1 and figure 2 As shown, the present invention provides a graphite metal reinforced gasket suitable for internal and external double-layer sealing. The gasket includes a metal outer ring 1, a metal middle ring 2, a metal inner ring 3, a trapezoidal graphite inner ring 4 and a trapezoidal graphite outer ring. Circle 5.

[0038] The metal outer ring 1 , the metal middle ring 2 , the metal inner ring 3 , the trapezoidal graphite inner ring 4 and the trapezoidal graphite outer ring 5 all need to make molds first, and make them through mold filling.

[0039] The metal outer ring 1 is provided with inner grooves, the metal middle ring 2 is respectively provided with grooves on the outer side and the inner side, and the metal inner ring 3 is provided with grooves.

[0040] Among them, there are two raised graphite shoulders on both sides of the trapezoidal graphite outer ring 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com