Application and device of a differential aerodynamic design in gas cluster beam source

An aerodynamic and gas cluster technology, applied in pump devices, mechanical equipment, machines/engines, etc., can solve the problem of expensive pump sets, achieve effective aerodynamic isolation, improve air pressure and condensation efficiency, and reduce consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

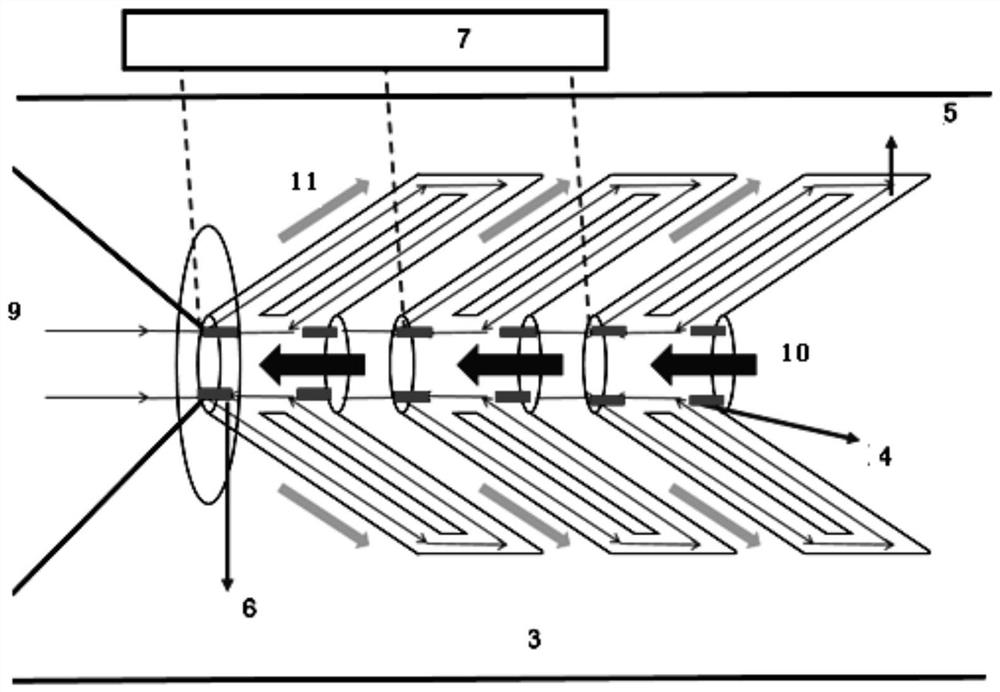

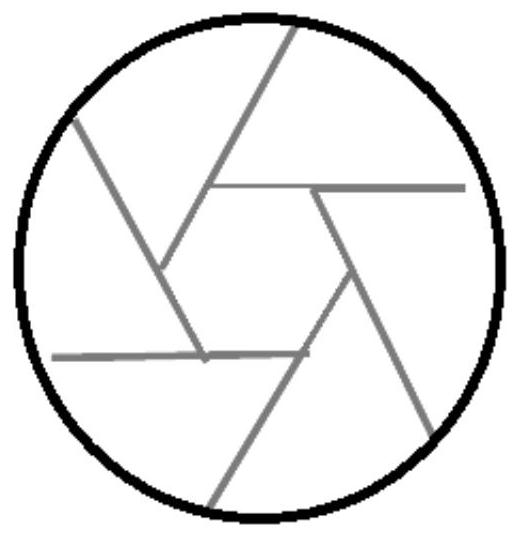

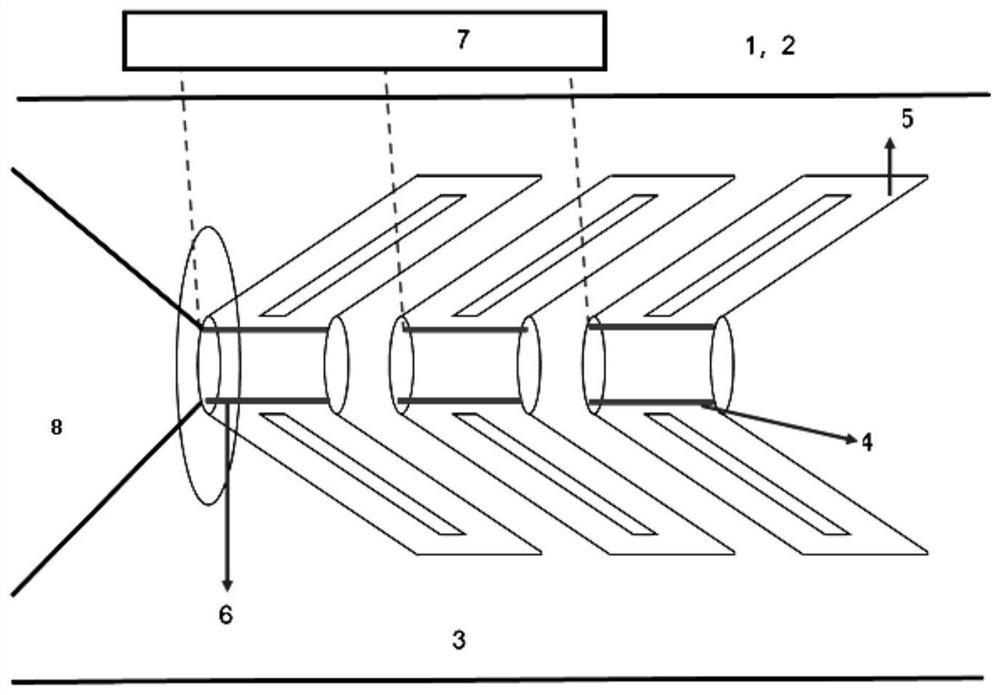

[0035] Such as figure 1 Shown, the present invention comprises: differential vacuum pump group comprises molecular pump 1, mechanical pump 2, has drawn the inlet that differential vacuum pump group provides among the figure; Track 4, Tesla non-movable microvalve half-circle track 5, straight track and semi-circle track externally controlled (aperture type) communication valve 6, external multi-channel controller 7. Condensation chamber outlet and high pressure chamber 8. High-pressure airflow 9, reverse flow resistance 10. Annular chamber flow 11.

[0036] Vacuum pump set of molecular pump mechanical pump: obtain high vacuum chamber environment.

[0037] Condensation chamber: The condensation chamber is the high pressure part of the differential pumping system, which can be used for the condensation growth of nanoparticles.

[0038] The Tesla non-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com