Preparation method of a modified copper three-dimensional framework and its application in lithium batteries

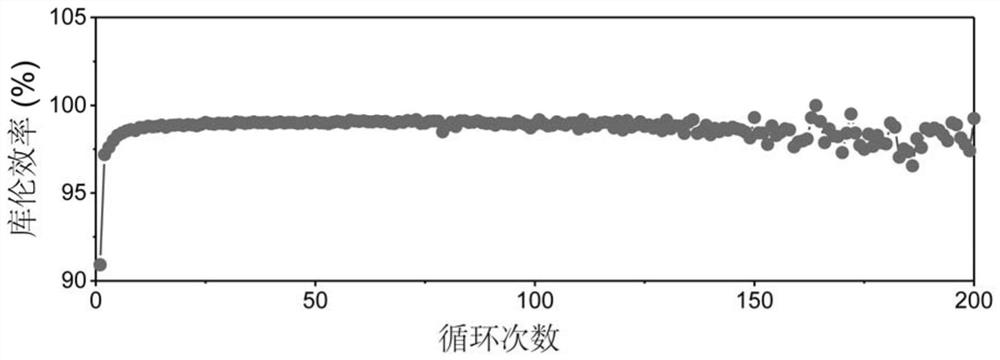

A three-dimensional skeleton and lithium battery technology, which is applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of low coulombic efficiency of lithium metal negative electrodes, achieve performance improvement, alleviate dead lithium, and achieve high coulombic efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

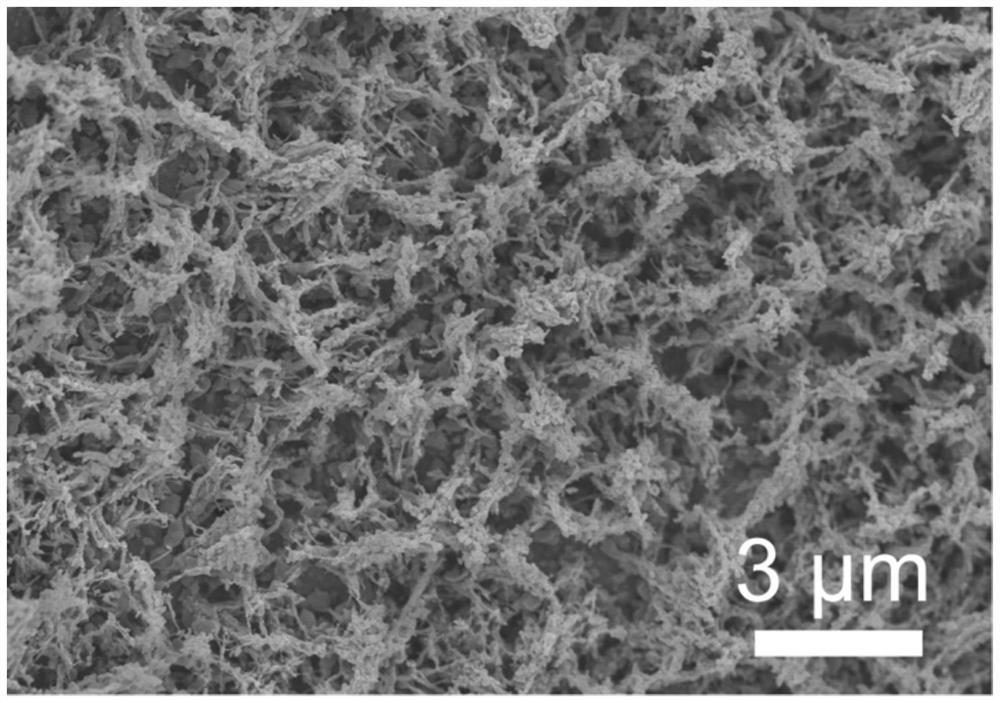

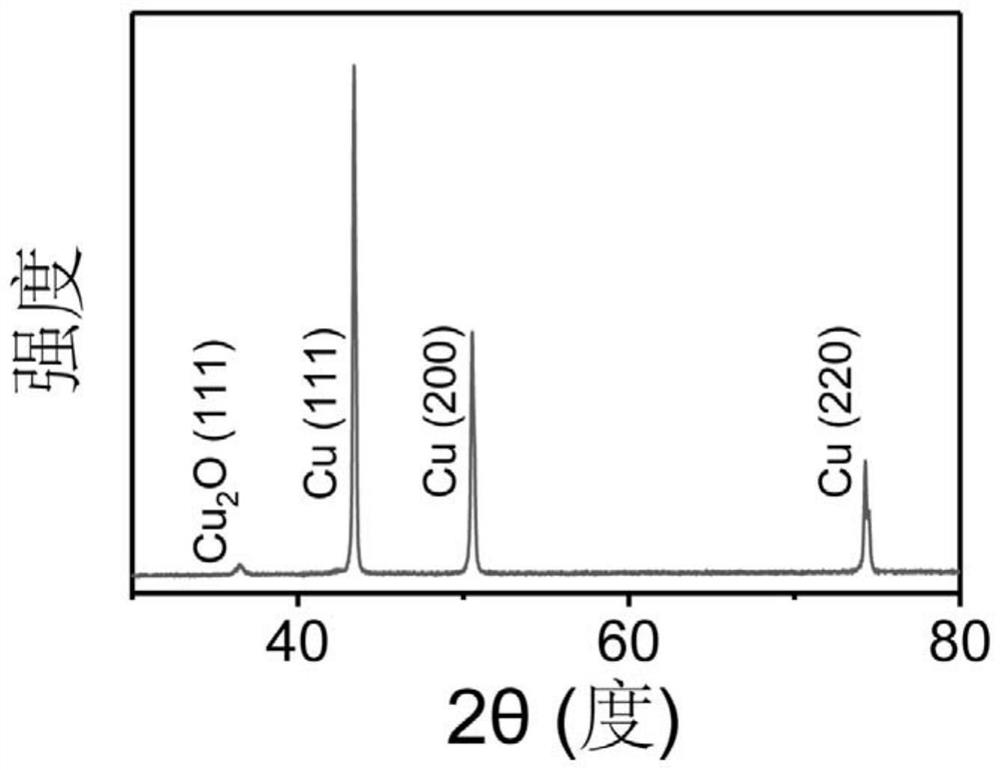

[0048] This embodiment provides a method for preparing a modified copper three-dimensional skeleton, the specific steps are as follows:

[0049] (1) Dissolve 2.8 grams of sodium hydroxide and 2.28 grams of ammonium persulfate in 80 milliliters of water as reaction solution A; mix 2.5 milliliters of water and 2.5 milliliters of dimethylformamide, and then take 10 milligrams of 1,3,5-homon Benzenetricarboxylic acid and 100 mg of polyvinylpyrrolidone were dissolved therein as reaction solution B;

[0050] (2) Immerse the cleaned copper foam (2cm×5cm×1cm) in reaction solution A and let it stand at 4°C for 22 minutes; then transfer it directly to reaction solution 2 and let it stand at 25°C for 10 minutes. After the reaction is completed, wash with water and alcohol and dry;

[0051] (3) Keep the dried copper foam in an argon atmosphere at 400° C. for 1 hour to obtain a modified copper three-dimensional framework.

[0052] The modified copper three-dimensional skeleton is tested ...

Embodiment 2

[0054] This embodiment provides a method for preparing a modified copper three-dimensional skeleton, the specific steps are as follows:

[0055] (1) Dissolve 3.2 grams of sodium hydroxide and 9.12 grams of ammonium persulfate in 80 milliliters of water as reaction solution A; mix 1 milliliter of water with 5 milliliters of dimethylformamide, and then take 25 milligrams of 1,3,5- Trimellitic acid and 6 mg of polyvinylpyrrolidone were dissolved therein as reaction solution B;

[0056] (2) Dip the cleaned copper grid (2cm×5cm×1cm) into reaction solution A and let it stand at 4°C for 22 minutes; then transfer it directly to reaction solution 2 and let it stand at 25°C for 10 minutes. After the reaction is completed, wash with water and alcohol and dry;

[0057] (3) Keep the dried copper grid in an argon atmosphere at 300° C. for 2 hours to obtain a modified copper three-dimensional skeleton.

Embodiment 3

[0059] This embodiment provides a method for preparing a modified copper three-dimensional skeleton, the specific steps are as follows:

[0060] (1) Dissolve 0.32 g of sodium hydroxide and 0.18 g of ammonium persulfate in 80 ml of water as reaction solution A; mix 5 ml of water with 1 ml of dimethylformamide, and then take 1.2 mg of 1,3,5- Trimellitic acid and 600 mg of polyvinylpyrrolidone were dissolved therein as reaction solution B as reaction solution B;

[0061] (2) Immerse the cleaned carbon conductive substrate (2cm × 5cm × 1cm, the thickness of the copper layer is 100μm) coated with copper in the reaction solution A, and let it stand at 4°C for 22 minutes; then directly transfer to the reaction solution In solution 2, let stand at 25°C for 10 minutes. After the reaction is completed, wash with water and alcohol and dry;

[0062] (3) Keep the dried carbon conductive substrate coated with copper on the other surface in an argon atmosphere at 500° C. for 1 hour to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com