Working liquor supplementing method for pulse copper plating process

A technology of working liquid and copper plating, applied in the direction of cells, electrolytic process, electrolytic components, etc., can solve the problems of no longer inhibiting and leveling, affecting the conductivity and current efficiency of the working liquid, sticking, etc., to achieve economical operation Time and labor, the effect of reducing waste water treatment and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

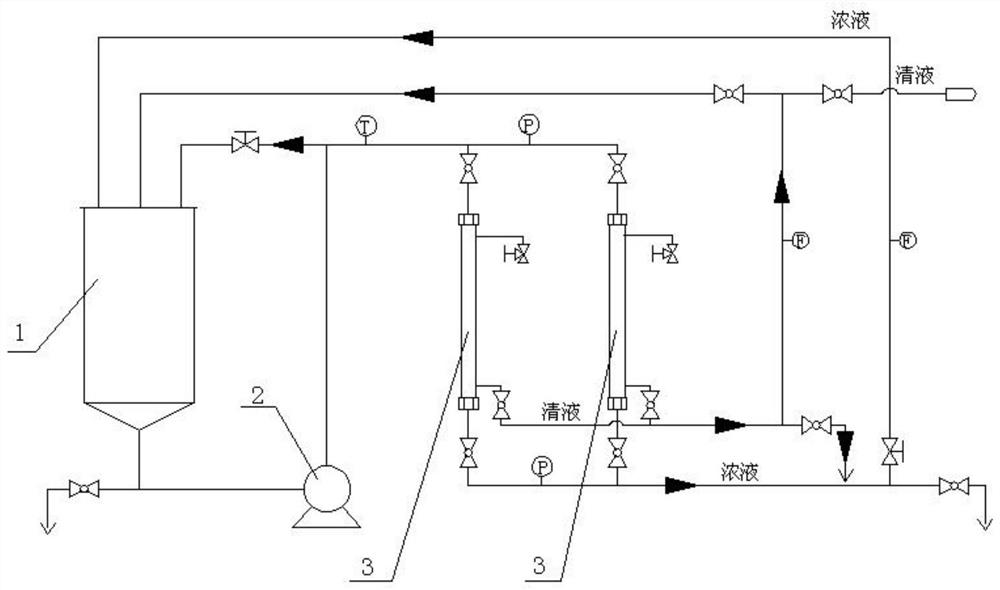

[0023] to combine figure 1 As shown, taking the vcp pulse electroplating line of a certain factory as an example, the electroplating line of this factory has 10 cylinders, and each cylinder has 6000 liters of bath liquid. After 30 days of electroplating work, many inhibitors and leveling agents have accumulated in the bath liquid. The decomposition products of the agent have some adverse effects on the current efficiency of the bath and the crystallization of copper, and it will not be able to meet the normal production needs if it continues;

[0024] For this reason, according to the working fluid replenishment method of the present invention, 10% of the total volume of the tank solution is taken in each cylinder respectively, that is, each cylinder gets 600 liters of tank solution, and the tank solution is delivered to the membrane filtration system through the circulation pump 2, The membrane filtration system in this embodiment adopts a plurality of ceramic membranes 3 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com