Steel bridge deck pavement structure for ultra-large span

A steel bridge deck and pavement technology, which is applied to bridges, bridge parts, bridge construction, etc., to achieve the effects of ingenious structure, moisture isolation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

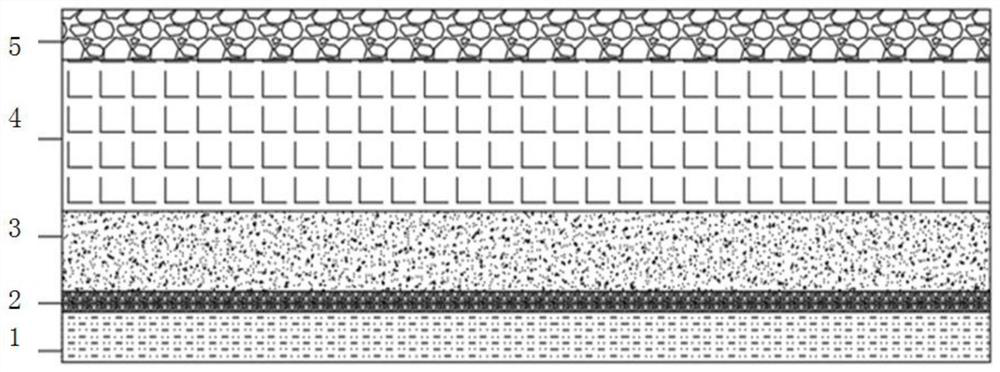

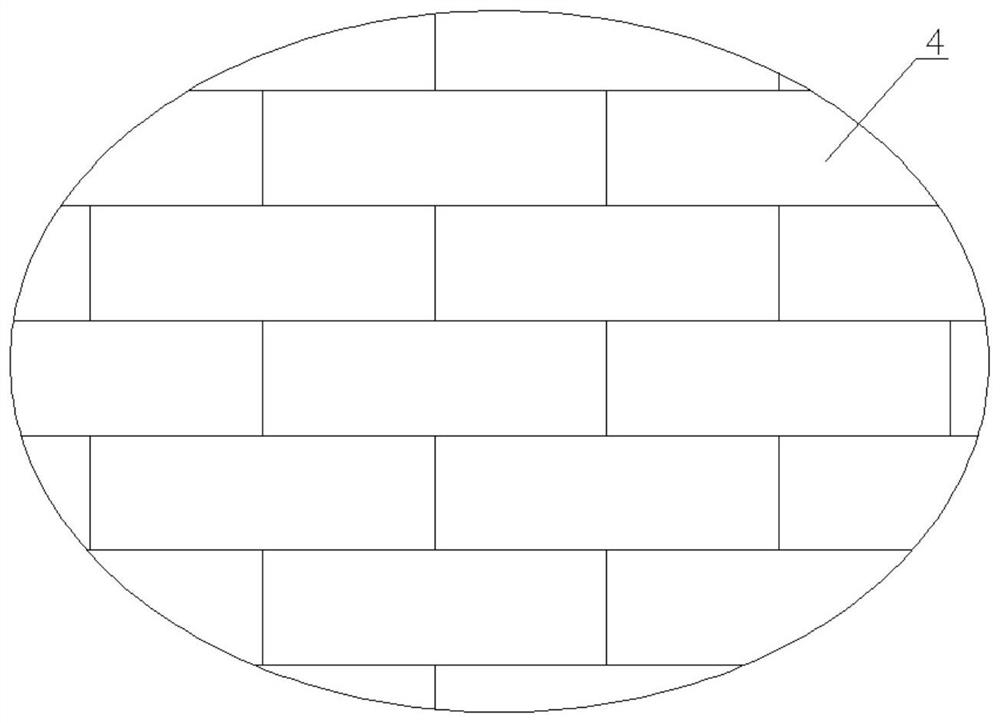

[0028] A steel deck pavement structure for very long spans, such as figure 1 , figure 2 and image 3 As shown, it includes an anti-corrosion layer 2, an elastic transition layer 3, a polymer prefabricated profile layer 4 and an anti-skid layer 5 laid sequentially on the steel bridge deck 1 (steel plate), between the elastic transition layer 3 and the polymer prefabricated profile layer 4 There is an adhesive layer between them; the elastic transition layer 3 and the anti-skid layer 5 are both integrally formed, and the specification of the single polymer prefabricated profile layer 4 is 6-12 meters long and 1-1.8 meters wide. The prefabricated profile layers 4 are connected in a way of overlapping or clamping, and the surfaces of all the connected polymer prefabricated profile layers 4 are located on the same plane.

[0029] Among them, the elastic transition layer 3 is made by blending reactive resin and filler with a particle size of less than 5 mm. The elastic transition...

Embodiment 2

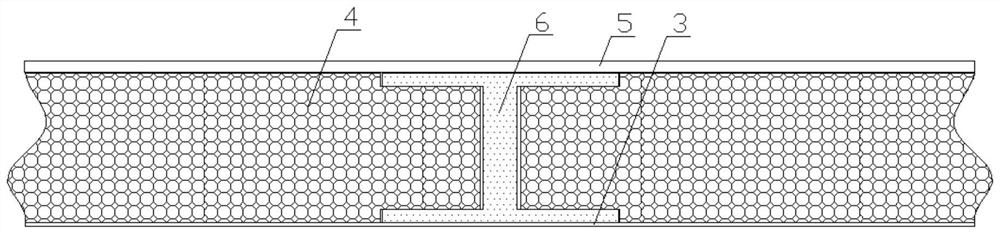

[0037] A kind of steel bridge deck pavement structure for ultra-large span, refer to embodiment 1 and combine Figure 4 As shown, its main difference from Example 1 is: the anti-slip layer 5 adopts a 5mm thick modified methacrylic resin layer; the polymer prefabricated profile layer 4 is a prefabricated hollow profile layer using modified ASA, and its thickness is 40mm 1. The hollow rate is 30%, and the holes corresponding to the hollow parts are round holes; the thickness of the elastic transition layer 3 is 15mm.

Embodiment 3

[0039] A steel bridge deck pavement structure for a super-long span, referring to Example 1, the main difference between it and Example 1 is that the prefabricated module layer is a prefabricated profile layer made of ASA, PA, PVC alloy, and its thickness is 30mm ; The thickness of the elastic transition layer 3 is 12mm.

[0040] Adopting the steel bridge deck pavement structure of the present invention, in the process of use, whether it is due to the change of bridge deck dynamic load or the disturbance of the steel bridge itself caused by wind force, it will not cause distortion and warping deformation of the steel bridge deck, which is solved ingeniously. The problem of twisting deformation and warping deformation of super long-span steel bridge deck during use is solved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com