Special-shaped fin structure design method for strengthening natural convection heat exchange

A technology of natural convection and structure design, applied in the field of fin structure design, can solve the problems of lack of theoretical basis, repeated design, simulation, improvement, natural convection heat dissipation effect of difficult fin structure, etc., to achieve excellent performance, reasonable design results, The effect of reducing design labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The method of the present invention can be used in the fin structure design for strengthening natural convection heat transfer in various heat dissipation devices. The embodiment adopts the structural design of the heat dissipation fin of a certain type of high-power LED lighting lamp. as an example.

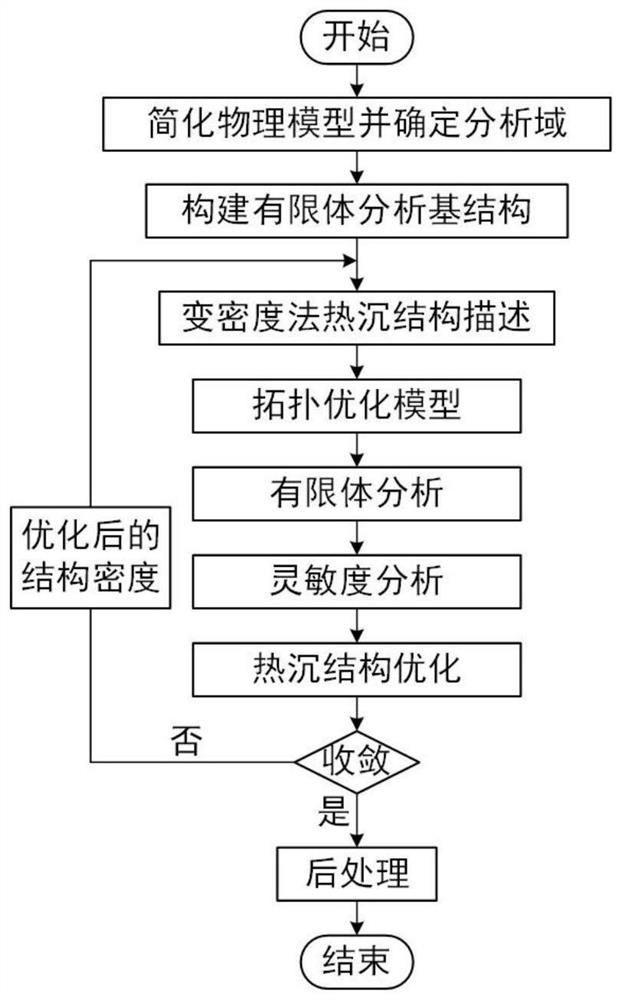

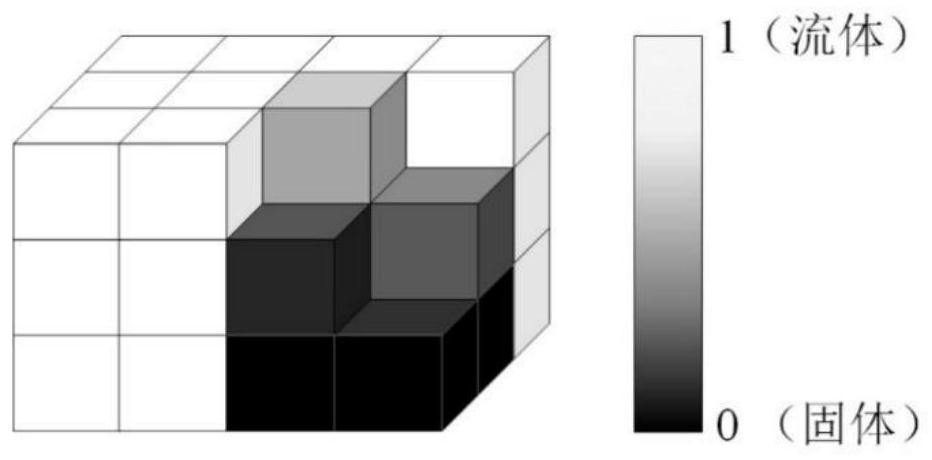

[0061] refer to figure 1 , a method for designing a special-shaped fin structure that enhances natural convection heat transfer, including the following steps:

[0062] 1) Determine the analysis domain and physical model of the natural convection heat transfer problem:

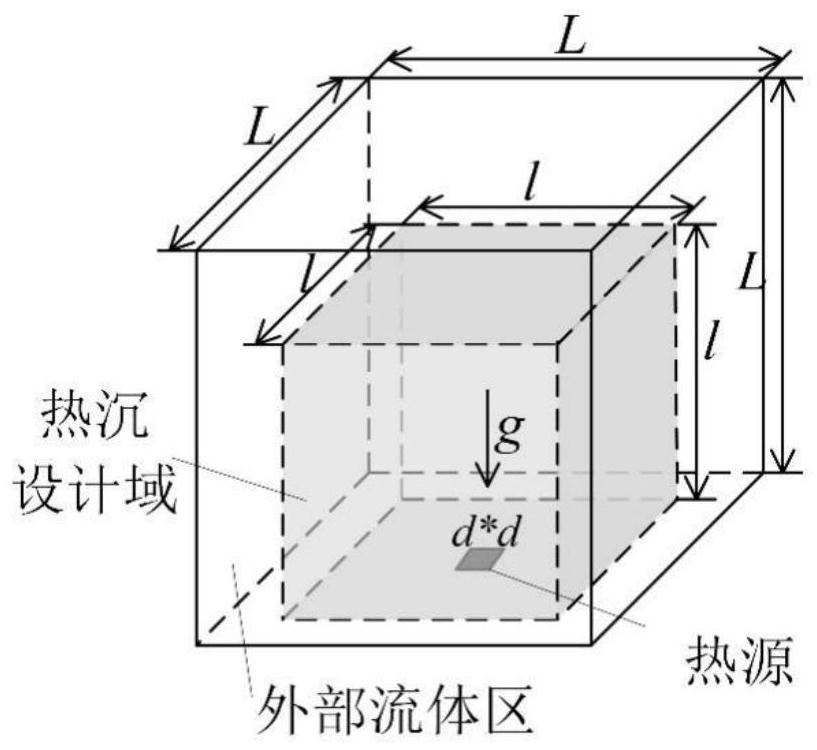

[0063] 1.1) According to the actual fin structure design problem, simplify and extract the domain to be analyzed and the key geometric and physical conditions; the analysis domain includes the fin structure to be optimized and the fin structure to interact with the fin and then conduct n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com