Compliant mechanism generation method based on zero-depletion grid curved surface continuous deformation

A compliant mechanism and grid technology, which is applied in the field of compliant mechanism generation based on continuous deformation of zero-genus mesh surfaces, can solve problems such as inability to form an optimal structure, complex optimization, and limitation of obtaining the optimal solution of topology optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings.

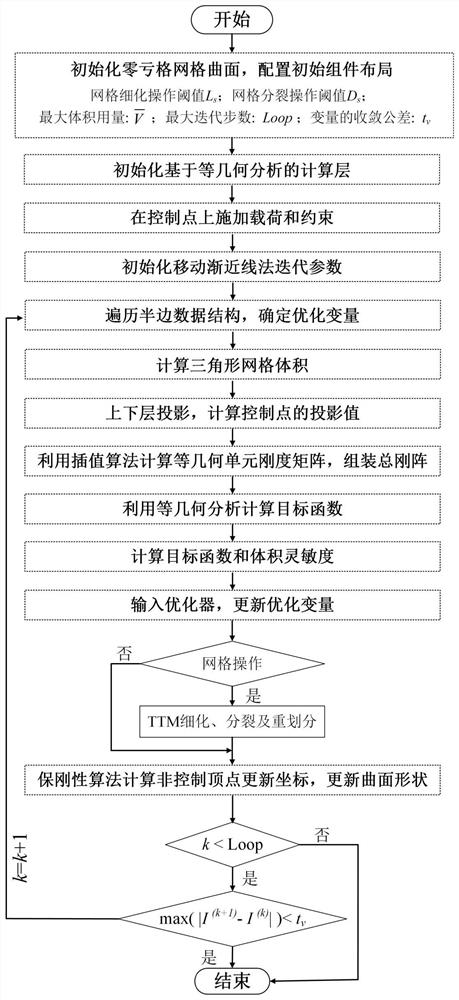

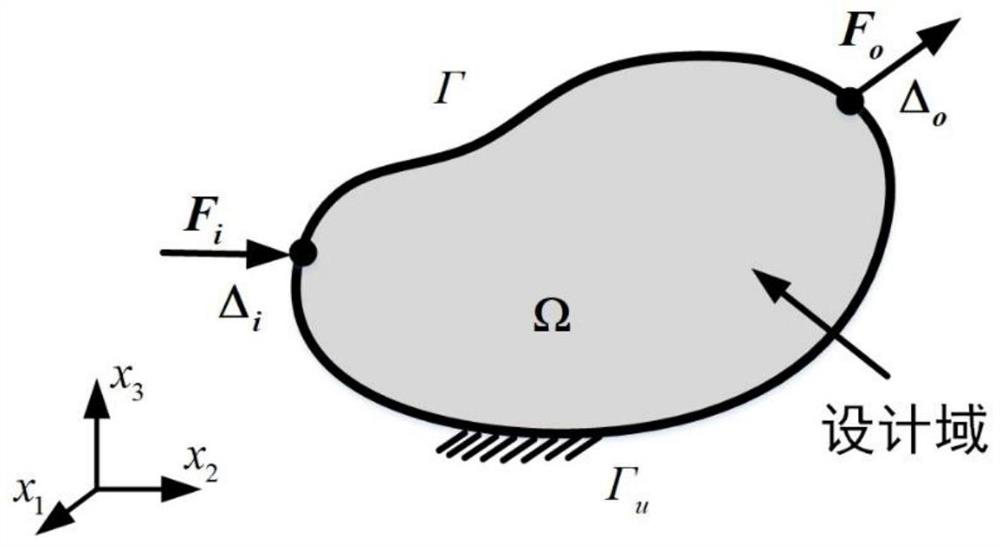

[0067] Such as figure 1 As shown in , a method for generating compliant mechanisms based on continuous deformation of zero-genus mesh surfaces includes the following steps:

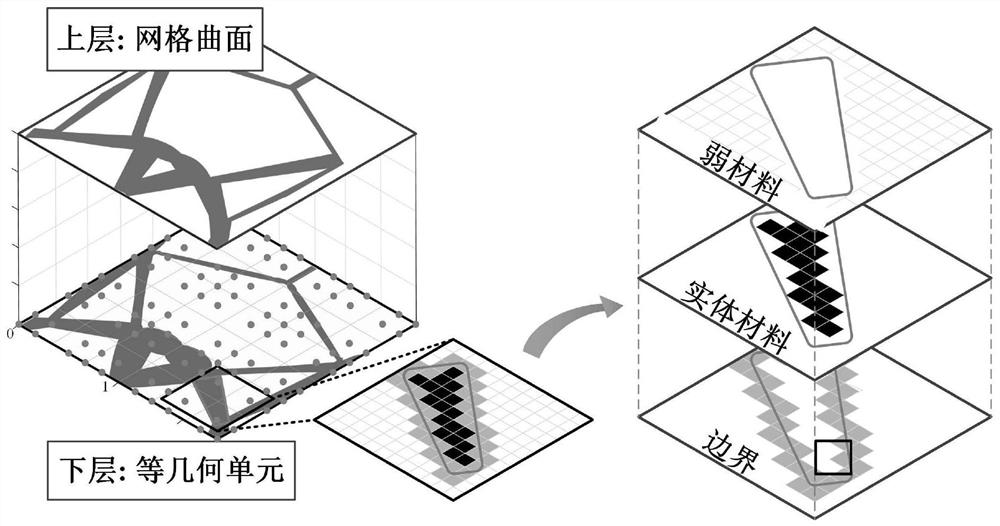

[0068] 1) Initialize the zero-genus grid surface and configure the initial component layout; set a series of vertex coordinates and connect the vertices to form geometry, and the parameterized geometry is further divided into smaller triangular grids to form the initial component layout described by the grid surface; Given the thresholds of triangle mesh refinement operation and splitting operation, respectively 25% and 30% of the shortest side of the design domain; set the upper limit of material consumption to 20%, set the maximum number of iteration steps to 1000, and the convergence standard for variable changes is 0.001;

[0069] When the triangular mesh surface is used for topolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com