Glass defect visual detection algorithm

A technology for visual inspection and glass defects, applied in computing, measuring devices, computer parts, etc., can solve problems such as poor performance, improve inspection efficiency and ensure yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

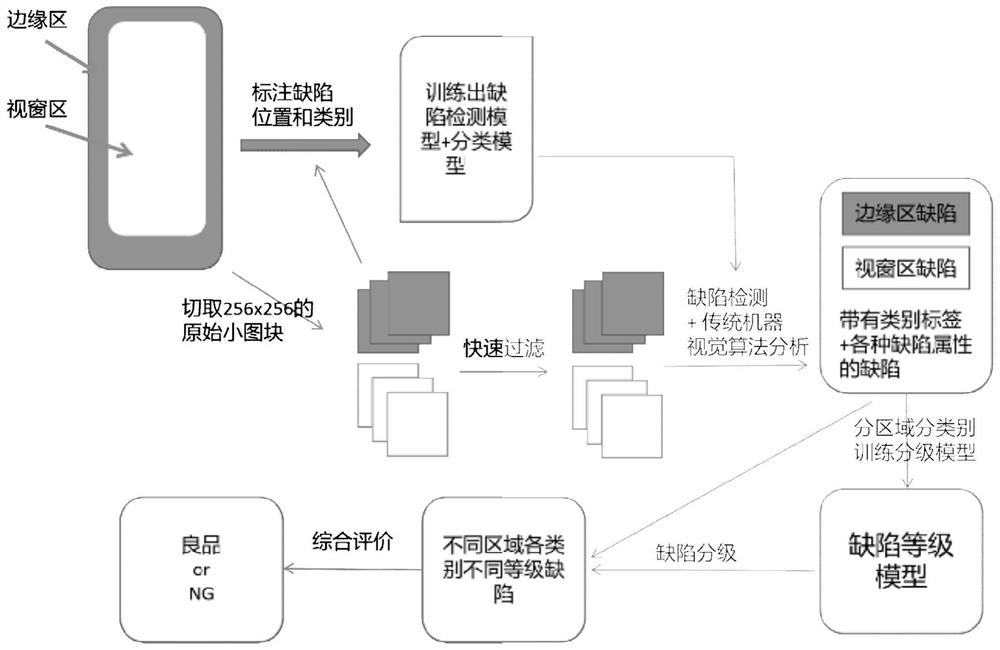

[0020] Aiming at the problems that algorithms in the prior art need to quickly switch products and screen defects in actual production, the present invention relates to a mobile phone glass defect detection technology, and provides a glass defect visual detection algorithm for finding each defect in the glass. Finally, evaluate whether the glass is good or not. It can maintain good detection stability during the process of product switching. By classifying and grading the defects, the required defects can be screened out, which not only ensures the production yield, but also ensures the production quality of the glass. .

[0021] The glass defect visual detection algorithm in the present invention can specifically adopt the following algorithm flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com