Device and method for monitoring printed containers

A container and equipment technology, which is applied in the field of monitoring printing containers, can solve problems such as printing head error step switching, and achieve the effect of high flexibility or adaptability and small storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

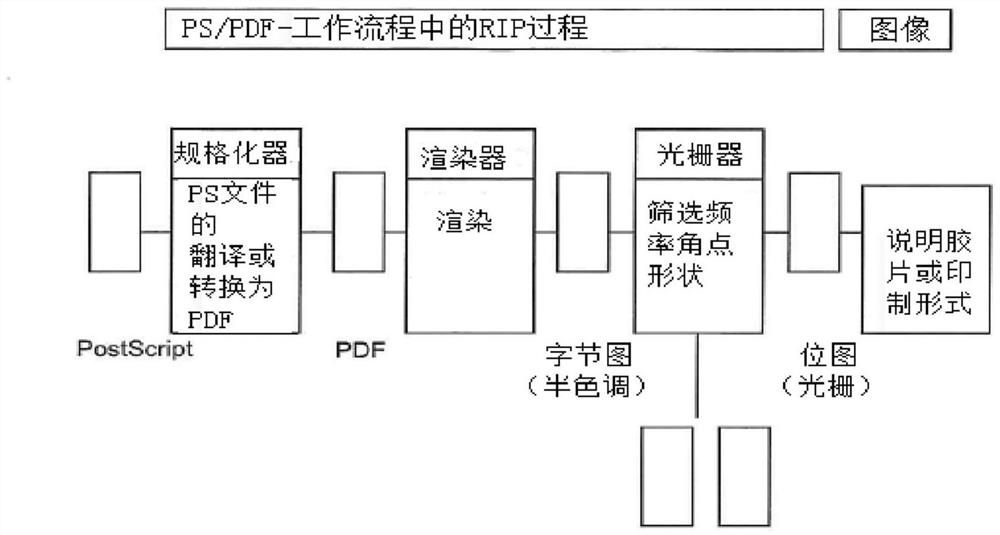

[0117] figure 1 A flowchart showing the RIP process in a PS / PDF workflow. The originally rendered PostScript document is converted into a PDF document by means of a so-called normalizer, by interpretation of the PS file or into PDF. This in turn is converted by a rendering process into a bytemap (halftone) and again into a bitmap (rasterizer) via a screening method via a so-called rasterizer. The resulting raster file can be used by the printing head of the printing assembly in a printing process known as a RIP file, which essentially employs a determined sequence and drop size of individual printing nozzles actuated in each possible printing color .

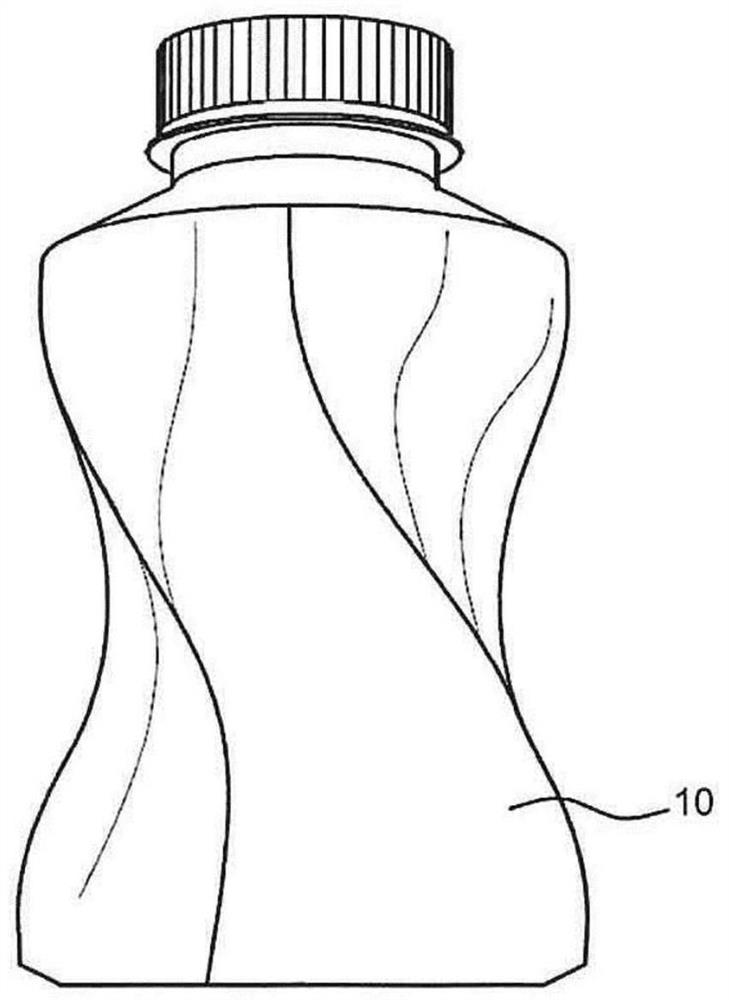

[0118] figure 2 An exemplary illustration of a container 10 to be printed is shown, for which the method or device according to the invention is particularly advantageous. The figure shows a container 10 in the form of a spiral, a so-called twisted container. Such containers can only be labeled with a so-called sleeve, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com