Vegetable and fruit jelly and preparation process thereof

A vegetable and fruit preparation technology, applied in the direction of food ingredients as antioxidants, functions of food ingredients, food science, etc., can solve the problem that jelly companies have no way to innovate consumer demand, affect consumers' eating experience, and limit the production of canning industry environment and other issues, to achieve the effect of good-looking appearance, rich production varieties, and enhanced aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

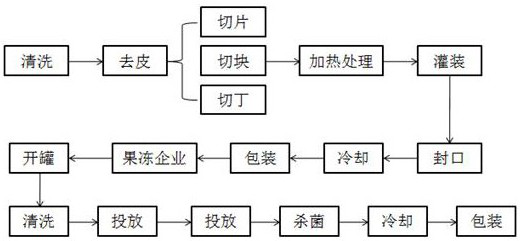

Image

Examples

Embodiment 1

[0055] A vegetable and fruit jelly is made from the following raw materials in parts by weight, including the following components: deionized water 65, fructose 10, sucrose 8, citric acid 0.12, sodium citrate 0.15, sucralose 0.005 , essence 0.08, sodium tripolyphosphate 0.03, potassium sorbate 0.04, sunset yellow 0.001. Carrageenan 0.25, Konjac Gum 0.30, Xanthan Gum 0.02, Locust Bean Gum 0.03, Apple Shredded 20.

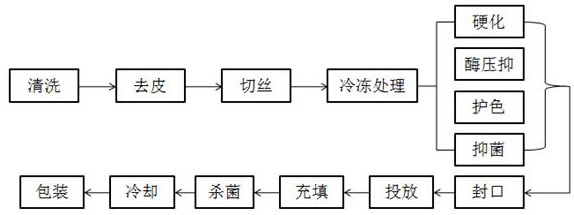

[0056] Its preparation process is as follows:

[0057] Step 1. Shredded vegetable and fruit pulp: select pineapples without rot and browning as raw materials, clean the skin, and directly peel and shred.

[0058] Step 2. Cold treatment of vegetable and fruit pulp: use 4°C cold calcium water for color protection and hardening treatment, and then perform color protection and anti-oxidation treatment through enzyme suppression process, color protection process, and antibacterial process.

[0059] Step 3. Filling treatment of vegetable and fruit pulp: After shredding, ...

Embodiment 2

[0063] A vegetable and fruit jelly is made from the following raw materials in parts by weight, including the following components: deionized water 72, fructose 10, sucrose 14, citric acid 0.28, sodium citrate 0.3, sucralose 0.005 , essence 0.10, sodium tripolyphosphate 0.03, potassium sorbate 0.05, sunset yellow 0.001. Carrageenan 0.28, konjac gum 0.35, xanthan gum 0.03, locust bean gum 0.04, wax gourd shreds 20.

[0064] Its preparation process is as follows:

[0065] Step 1. Shredded vegetable and fruit pulp: select pumpkins without rot and browning as raw materials, clean the skin, and directly peel and shred.

[0066] Step 2. Cold treatment of vegetable and fruit pulp: use 4°C cold calcium water to add D-sodium erythorbate for color protection and hardening treatment, and then perform color protection and anti-oxidation treatment through enzyme suppression process, color protection process, and antibacterial process.

[0067] Step 3. Vegetable and fruit pulp filling tre...

Embodiment 3

[0070] A vegetable and fruit jelly is made from the following raw materials in parts by weight, including the following components: deionized water 62, fructose 5, sucrose 9, citric acid 0.1, sodium citrate 0.1, sucralose 0.005 , essence 0.08, sodium tripolyphosphate 0.03, potassium sorbate 0.03, sunset yellow 0.001. Carrageenan 0.35, konjac gum 0.2, xanthan gum 0.05, locust bean gum 0.05, wax gourd shreds 20.

[0071] Its preparation process is as follows:

[0072] Step 1. Shredded vegetable and fruit pulp: select shredded pumpkins, pears, and carrots without rot and browning as raw materials, and clean the skin; spray or soak in salt water when peeling, and then shred.

[0073]Step 2. Cold treatment of vegetable and fruit pulp: adding cold calcium water at 4°C for color protection and hardening treatment, and then through low-temperature enzyme suppression process and antibacterial process.

[0074] Step 3. Vegetable and fruit pulp filling treatment: add water at 85°C to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com