Digital manufacturing method based on Loactor planting base

A manufacturing method and abutment technology, which are used in manufacturing auxiliary devices, electrical digital data processing, dental implants, etc., can solve problems such as displacement deviation, oral distribution, and achieve good technical support and guarantee, fast and accurate manufacturing, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0061] The Loactor implant abutment is an oral auxiliary medical device often used in middle-aged and elderly patients with edentulous jaws. Usually, there are 2-4 abutments in the patient's mouth, which are fixed on the implant in the patient's mouth by screws. The auxiliary retention ring is attached to the Loactor implant abutment, and the matching retention rubber pad is installed on it, and the retention rubber pad is installed in the complete denture, which can effectively solve the problem of insufficient retention force of the complete denture

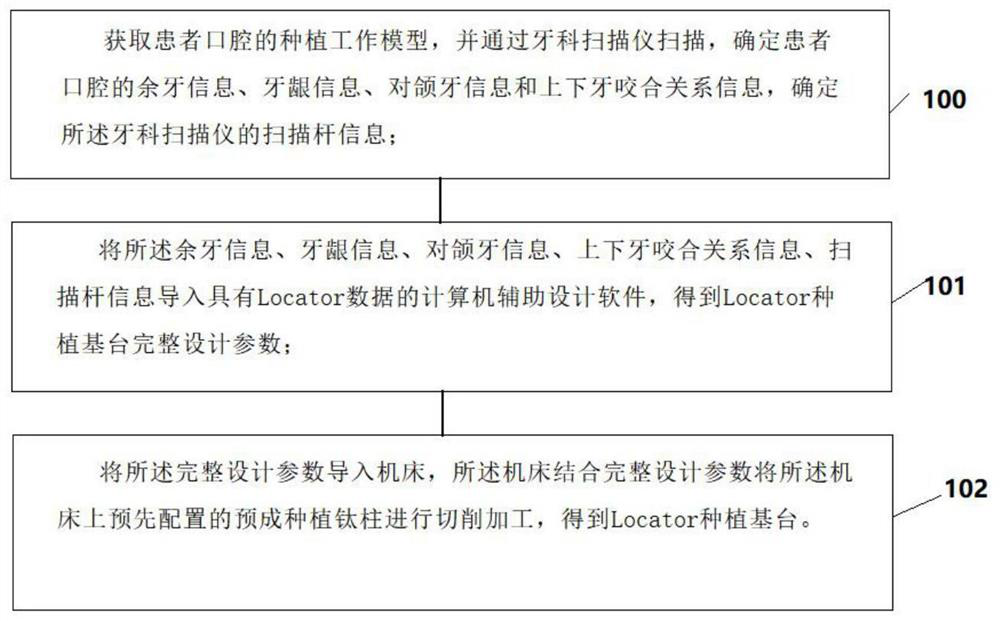

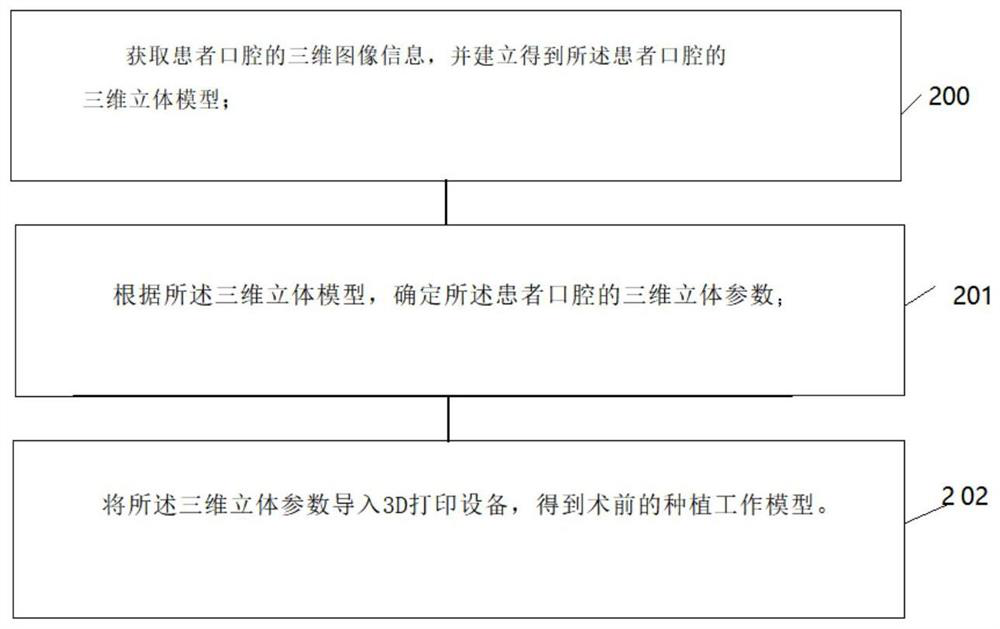

[0062] A digital manufacturing method based on a Loactor implant abutment, comprising:

[0063] Step 100: Obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com