Directly-heated type second-class heat pump

A direct heating and heat pump technology, which is applied in the field of industrial waste heat recovery, can solve the problems of inability to use the waste heat heat source of industrial sewage and wastewater that are prone to scaling, and achieve the effects of reducing heat loss, realizing concentrated treatment, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

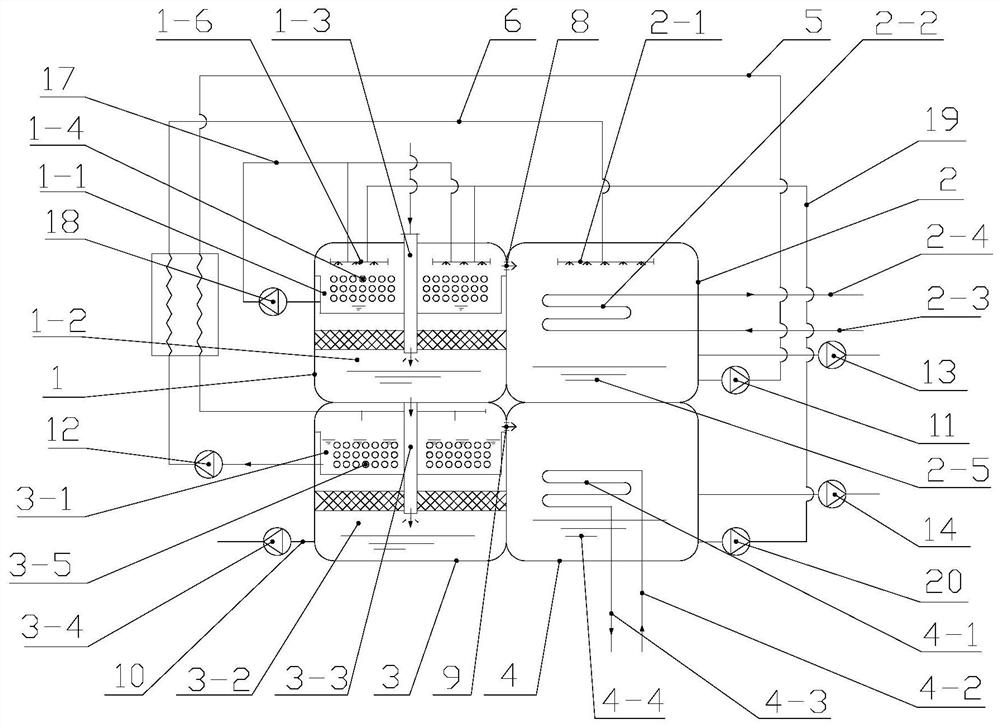

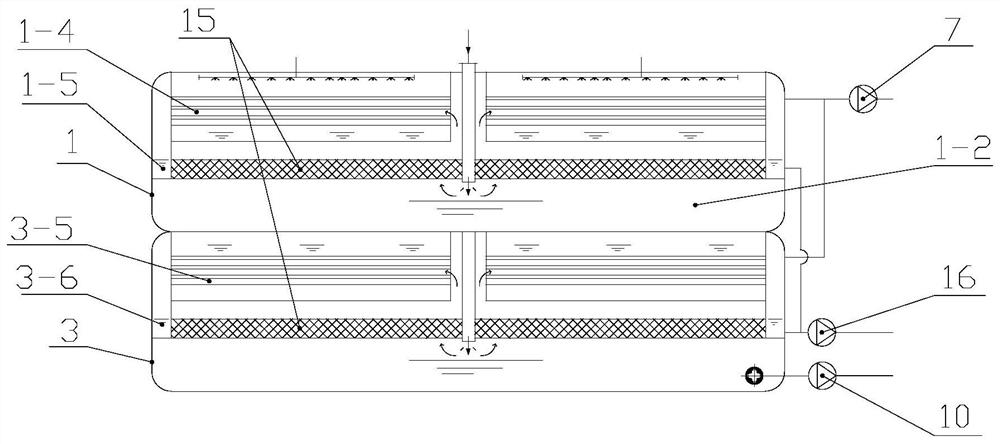

[0031] Specific implementation mode one: combine Figure 1~6 Describe this embodiment, direct heating type II heat pump, it comprises evaporator (1), absorber (2), generator (3) and condenser (4),

[0032] Wherein the evaporator (1) includes a refrigerant water chamber (1-1) located on the upper part and a first flash chamber (1-2) located below the refrigerant water chamber (1-1), and the refrigerant water passes through the tube The road enters the refrigerant water cavity (1-1);

[0033] Described generator (3) comprises the lithium bromide solution chamber (3-1) that is positioned at the top and is positioned at the second flash chamber (3-2) below lithium bromide solution chamber (3-1), lithium bromide solution chamber (3-1) The upper part of the upper part and the lower part of the absorber (2) are connected through a dilute lithium bromide solution pipe (5), and the lower part of the lithium bromide solution chamber (3-1) and the upper part of the absorber (2) are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com