Vertical sintering furnace for single-ended glass-sealed thermistor

A thermistor and sintering furnace technology, which is applied in the direction of resistors, resistor manufacturing, furnaces, etc., can solve the problems of single-ended component resistance change, reliability reduction, and forming asymmetry, and achieve continuous feeding and processing efficiency high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The following is attached Figure 1-8 Further detailed description of the present invention:

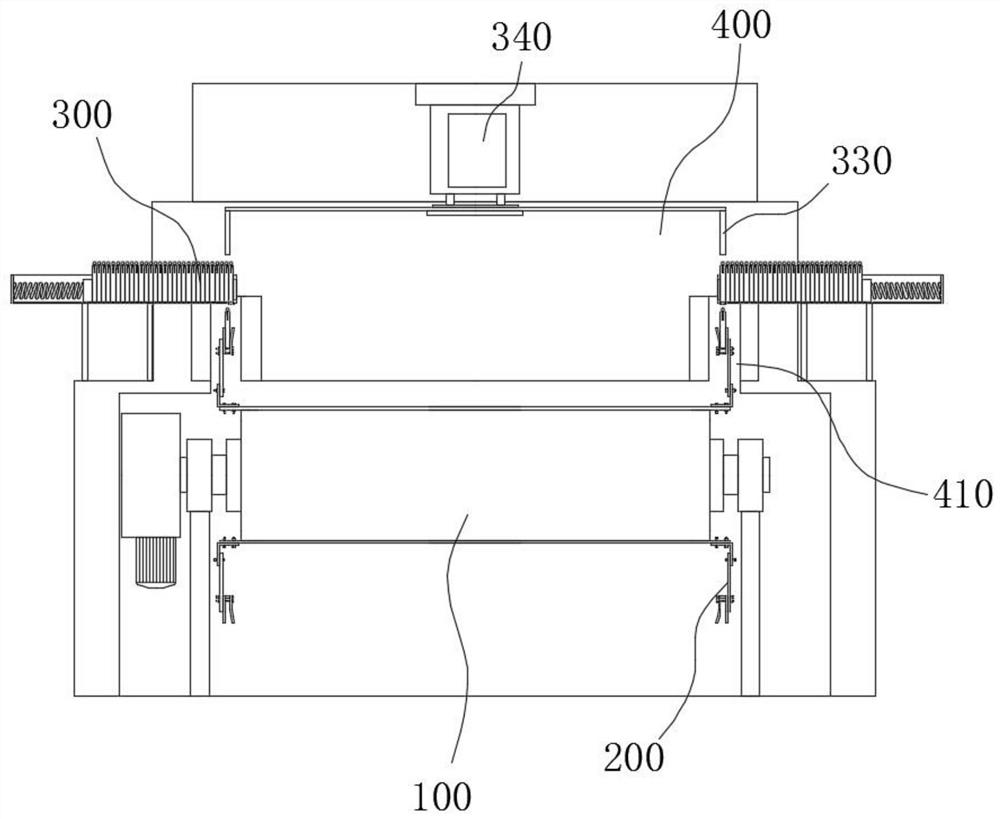

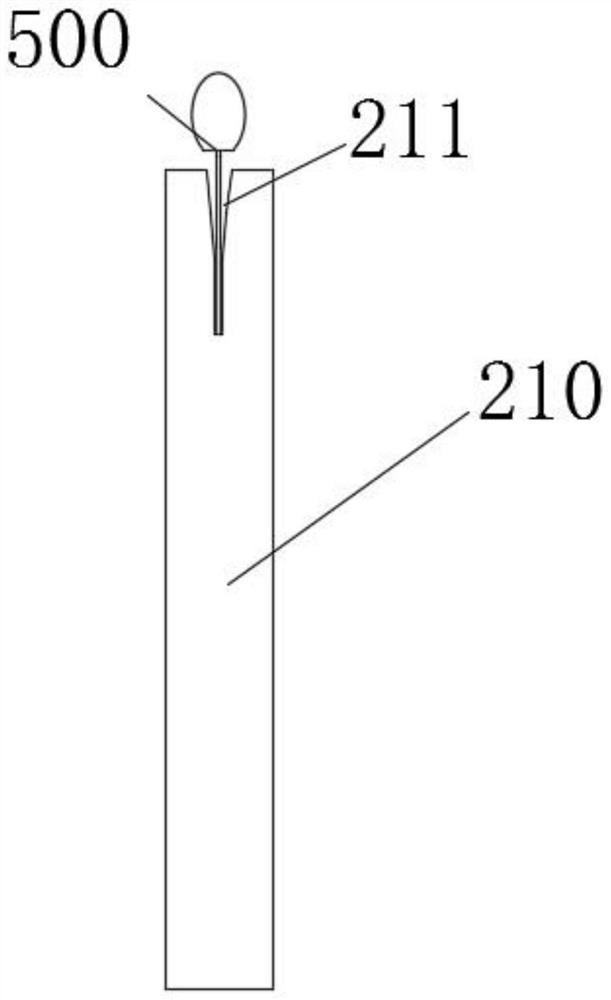

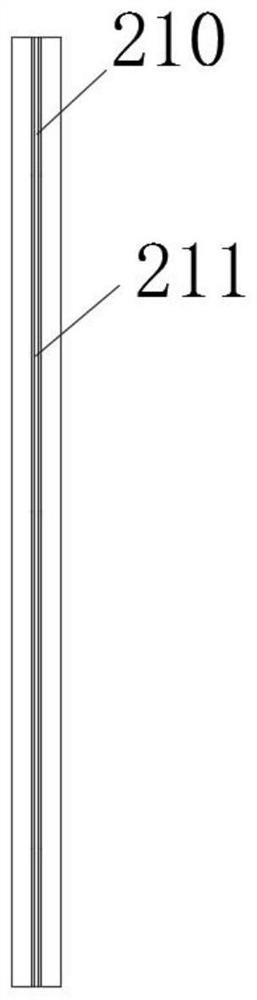

[0043] refer to figure 1 and Figure 8, a single-ended glass-sealed thermistor vertical sintering furnace, including a conveyor belt 100 and a sintering furnace 400, the conveyor belt 100 is arranged horizontally, the sintering furnace 400 and the conveyor belt 100 are arranged correspondingly, and the sintering furnace 400 is arranged along the conveyor belt 100 The conveying direction is provided with a furnace 410 opening downwards. The conveyor belt 100 is used to transport the element 500 through the furnace 410. The element 500 passes through the furnace 410 in a vertical shape on the conveyor belt 100. The upper end of the element 500 is sleeved with a glass sealing element. The glass bulb 510 on the 500 upper end. Through the setting of the conveyor belt 100, the function of conveying the element 500 is realized. The element 500 passes through the hearth 410 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com