Engine timing cover cap lightweight CAE analysis method

An analysis method and engine technology, applied in geometric CAD, CAD numerical modeling, design optimization/simulation, etc., can solve problems such as large differences in structural stress states, large noise, large vibration, etc., to achieve convenient design and verification, The effect of reducing workload and speeding up development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

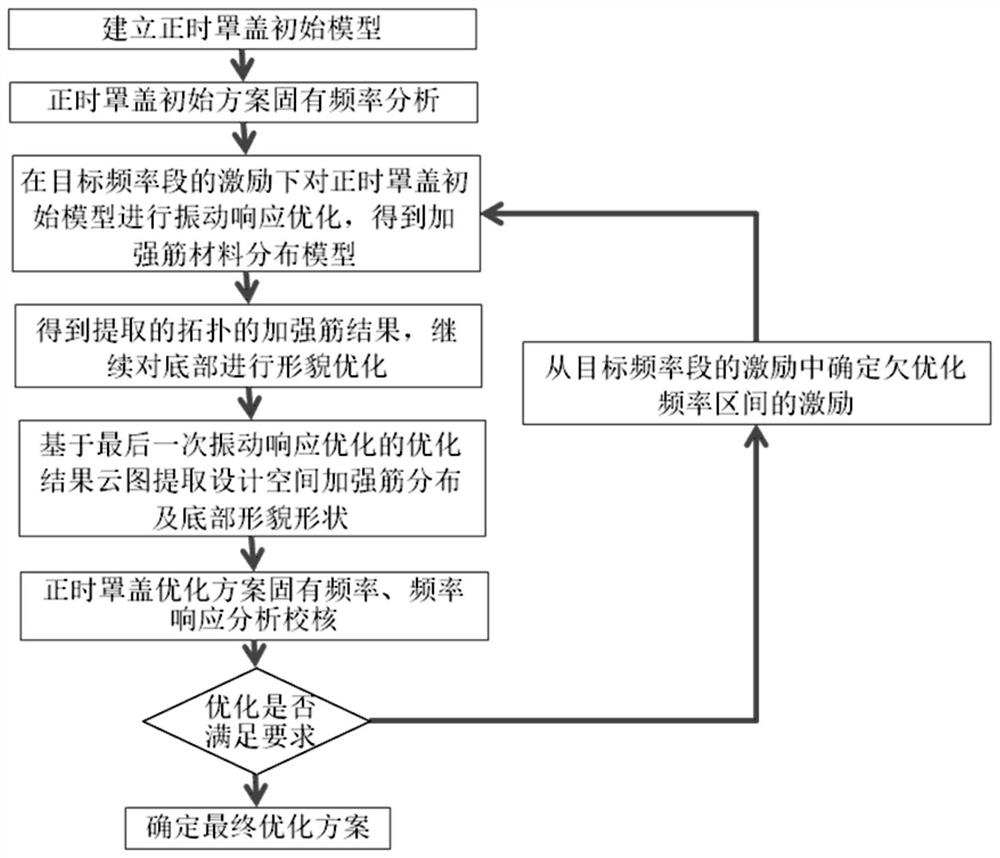

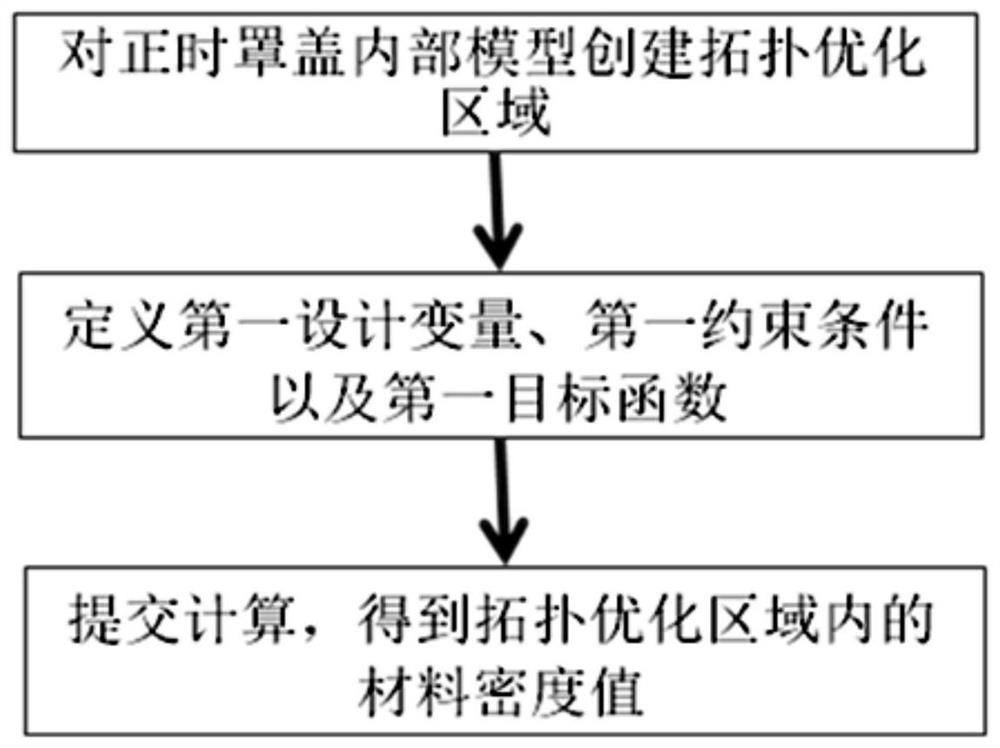

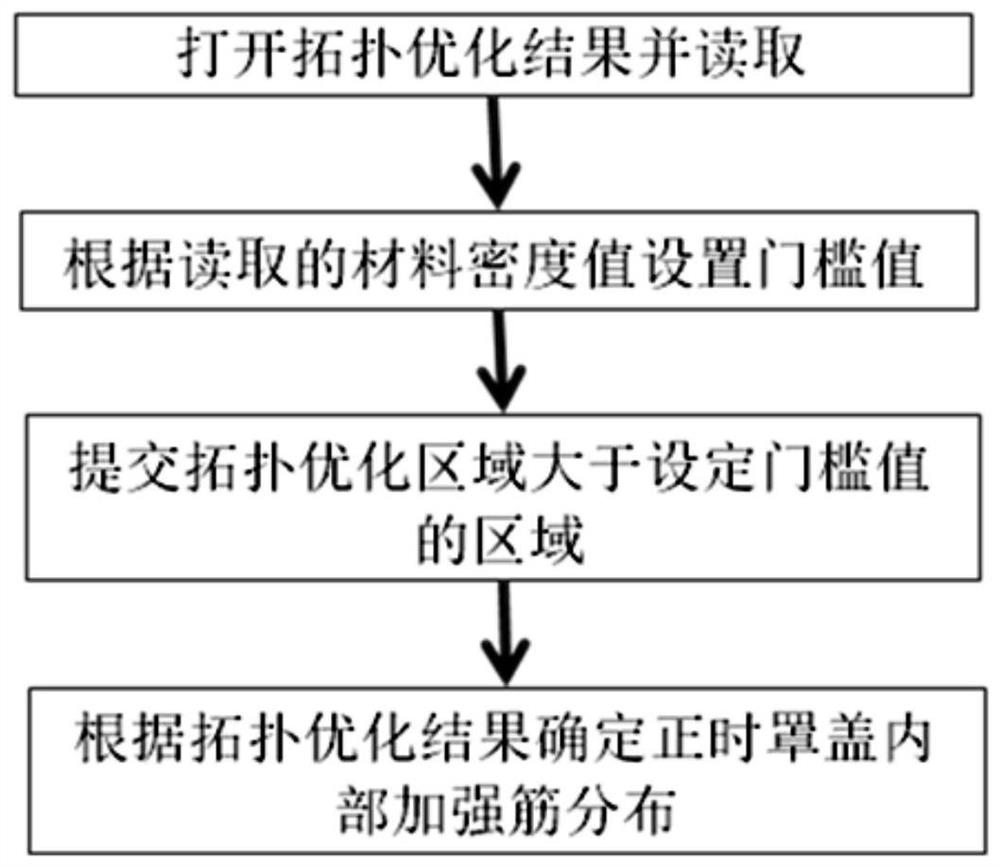

[0044] Such as figure 1 As shown, the present invention provides a lightweight CAE analysis method for an engine timing cover, comprising the following steps:

[0045] S1. Establish the finite element model of the initial scheme of the timing cover. The finite element model of the initial scheme of the timing cover includes the shell part and the initial rib part. The initial rib part is filled in the design space, and the design space is the initial timing cover. The space allowed for the arrangement of stiffeners in the coordinate system of the scheme finite element model;

[0046] S2. Carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com