A nled pixel setting and repair method

A repair method and pixel technology, applied in identification devices, static indicators, instruments, etc., can solve the problems of difficult chip operation, difficult pixel defect monitoring and repair, and low device yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

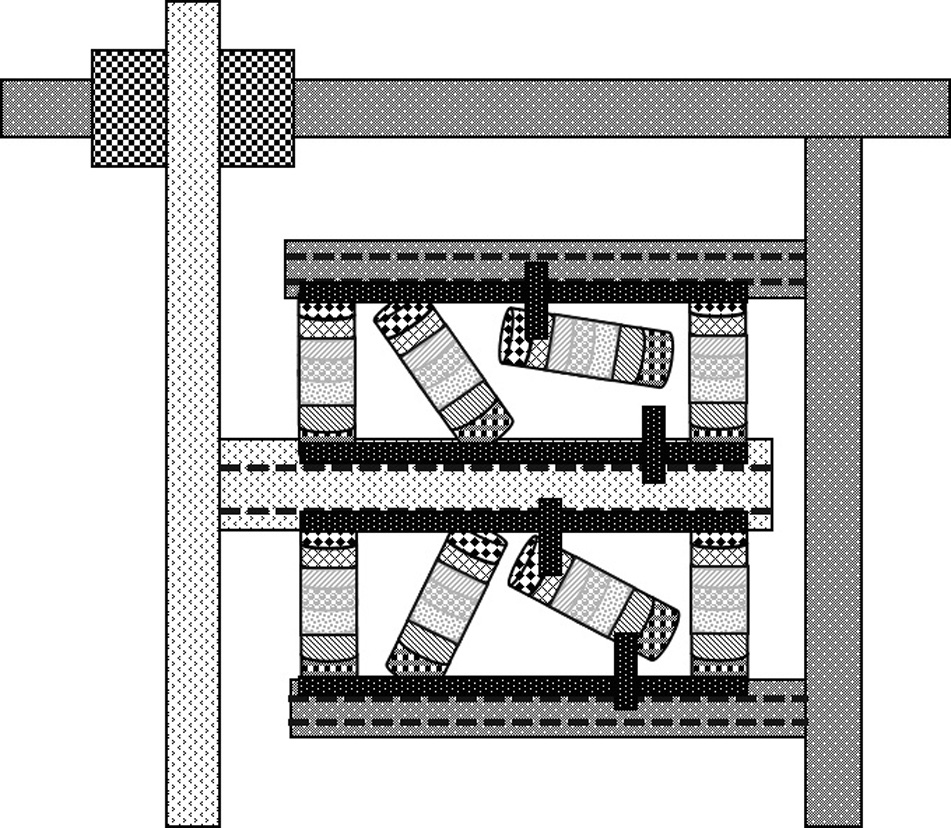

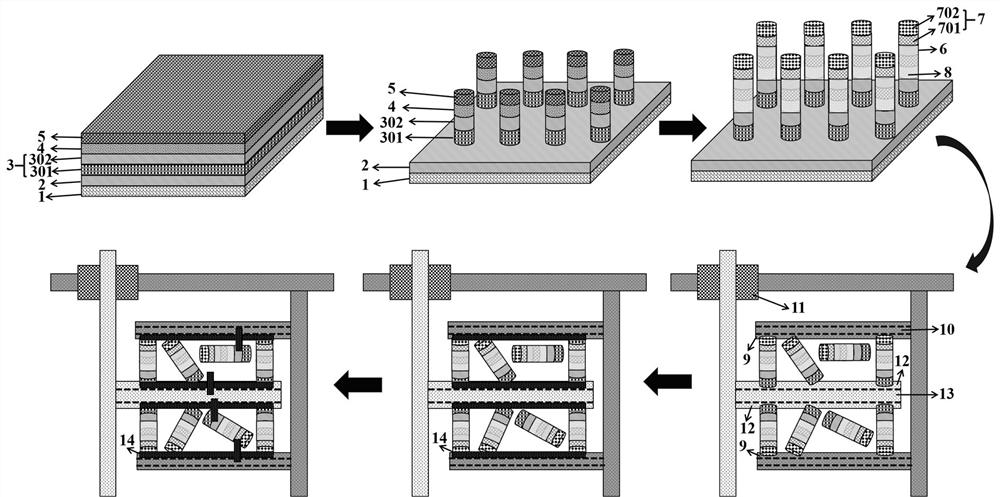

[0039] Please refer to figure 1 and figure 2 , the present invention discloses an NLED electrode arrangement scheme and interconnection method, each light-emitting pixel unit includes 8 NLED chips; the n-electrode of the NLED chip is provided with a first electrode interconnection region 301 of an n-type semiconductor and an n-type semiconductor The first electrode spare area 302 of the p-electrode is provided with the second electrode spare area 701 of the p-type semiconductor and the second electrode interconnection area 702 of the p-type semiconductor; the cathode of the driving backplane is provided with the cathode interconnection area 12 and the cathode spare area 13. The anode of the driving backplane is also provided with an anode interconnection area 9 and an anode spare area 10; the transfer arrangement of the NLED chip in the pixel area adopts electrophoresis; the interconnection mode of the NLED chip electrode and the pixel electrode of the driving backplane is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com