High-precision dielectric strip line broadside coupler

A broad-side coupling and high-precision technology, applied in the field of energy coupling technology, can solve the problems of low yield of printed boards and high requirements for coincidence accuracy, reduce position accuracy requirements, save time and labor costs, and improve finished products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

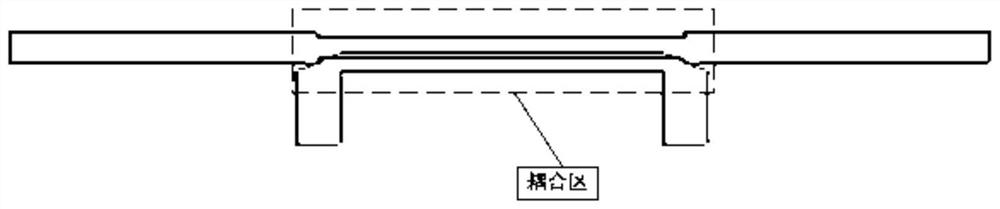

[0016] The structure of the directional coupler is as figure 1 As shown, generally there are two transmission lines, the main line and the auxiliary line, and four ports. If one port of the main line is selected as the signal input port, then the two ports of the auxiliary line, one is a coupled port, and the other is an isolated port. Signal transmission is reciprocal between the two ports.

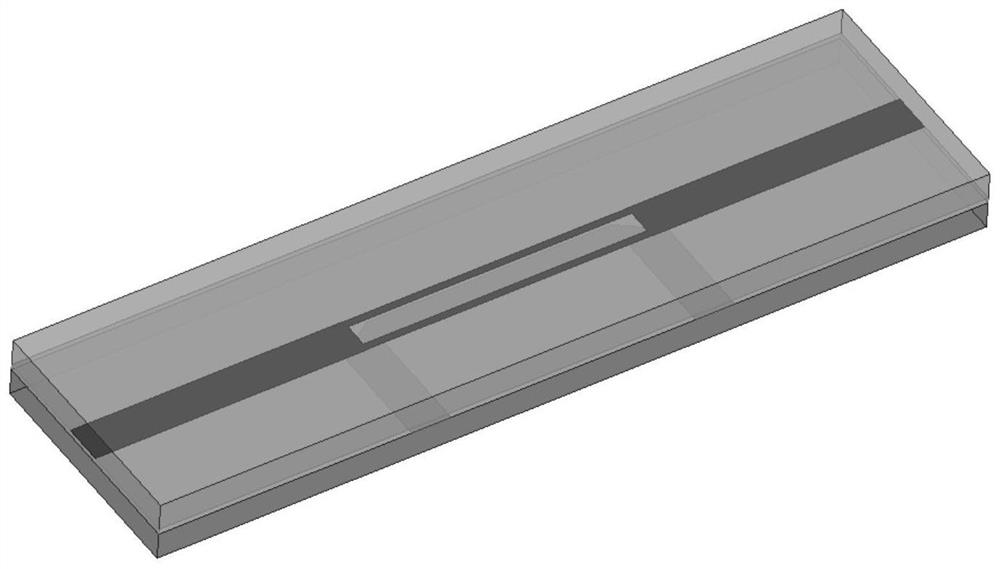

[0017] The circuit of the dielectric stripline broadside coupler is as follows figure 2 As shown, the microwave printing plate is used to make printed graphics, the medium uniformity is good, and the graphics processing precision is high. A conventional dielectric stripline broadside coupler is usually composed of three printed boards stacked. The upper and lower printed boards have a structure with no copper foil on one side and one side with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com