Heat accumulating type electric heating high-temperature electrode leading-out device

A technology of electrode extraction and electric heating, applied in the direction of ohmic resistance electrodes, ohmic resistance heating parts, etc., can solve the problems of high temperature aging of seals, poor cooling effect, hidden safety hazards, etc., achieve stable sealing performance and increase installation space , the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

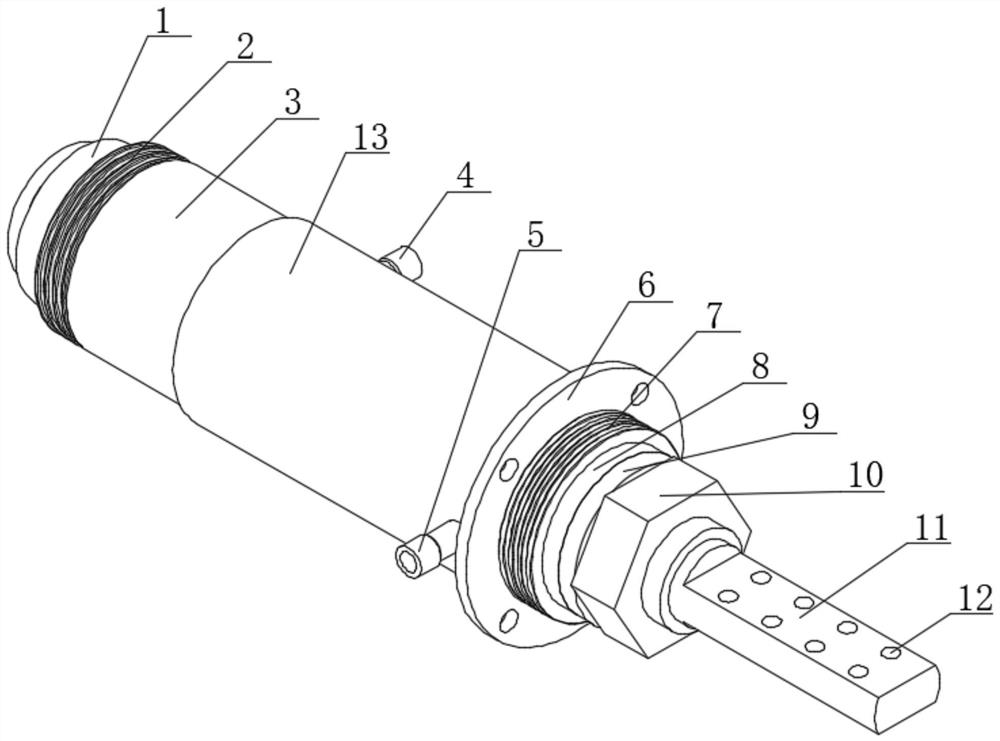

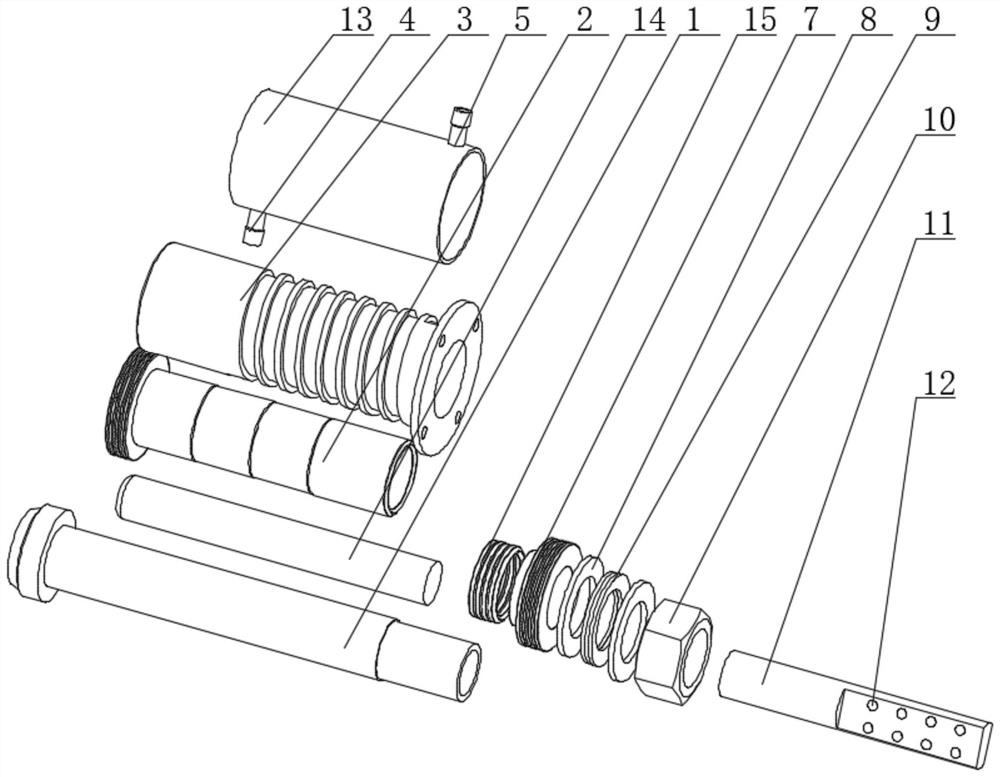

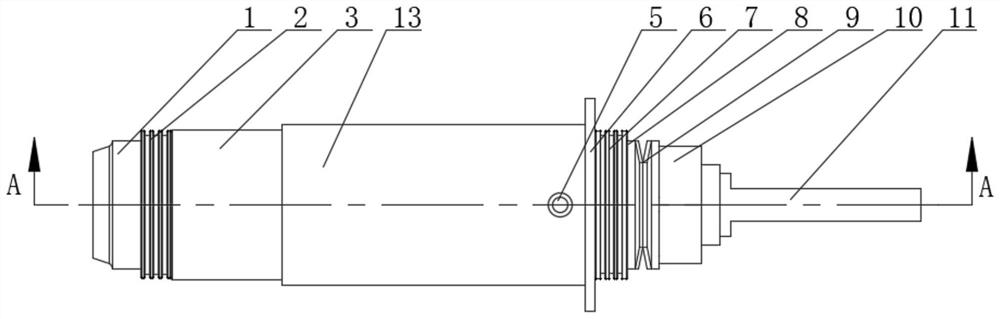

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0038] Such as Figure 1-Figure 7 As shown, the regenerative electric heating high-temperature electrode lead-out device of this embodiment includes an electrode lead-out section 1. A cavity 104 with a "U"-shaped cross section is opened in the middle of the electrode lead-out section 1, and the cavity 104 is filled with ceramics. Fiber heat insulation cotton 14, the electrode connection section 11 is installed in cooperation with the tail of the cavity 104 filled with ceramic fiber heat insulation cotton 14;

[0039] The outer peripheral surface of the electrode lead-out section 1 is fitted with a first insulating ceramic 2, and the electrode lead-out section 1 at the tail of the first insulating ceramic 2 is sequentially covered with a V-shaped sealing ring 15 and a second insulating ceramic 7, the first insulating ceramic 2 and The oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com