Plastic bottle recycling and separating device

A separation device and plastic bottle technology, applied in plastic recycling, recycling technology, metal processing and other directions, can solve the problems of complex device process, low separation efficiency, large workload, etc., to reduce labor intensity, rapid and convenient separation, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

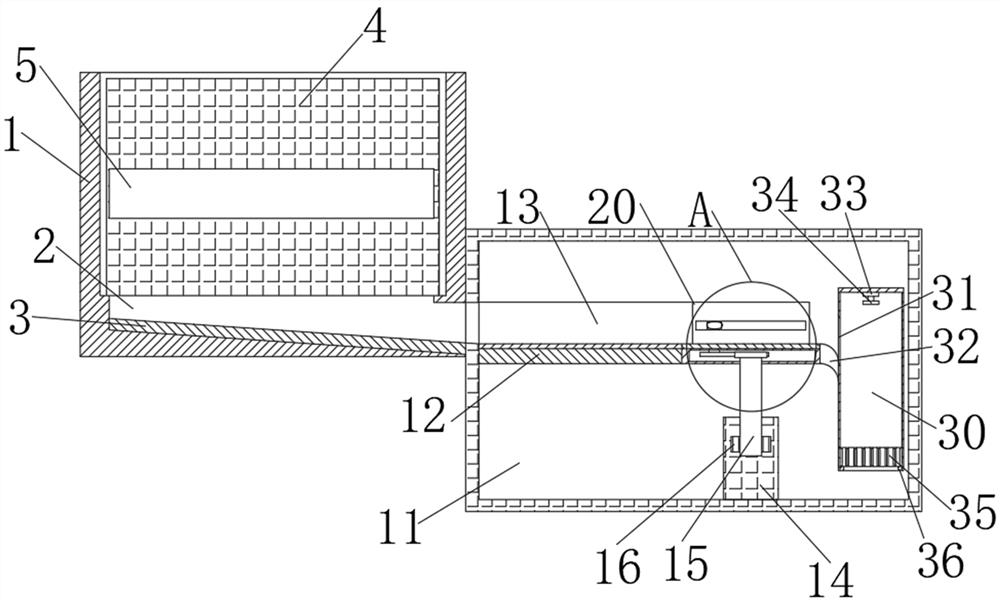

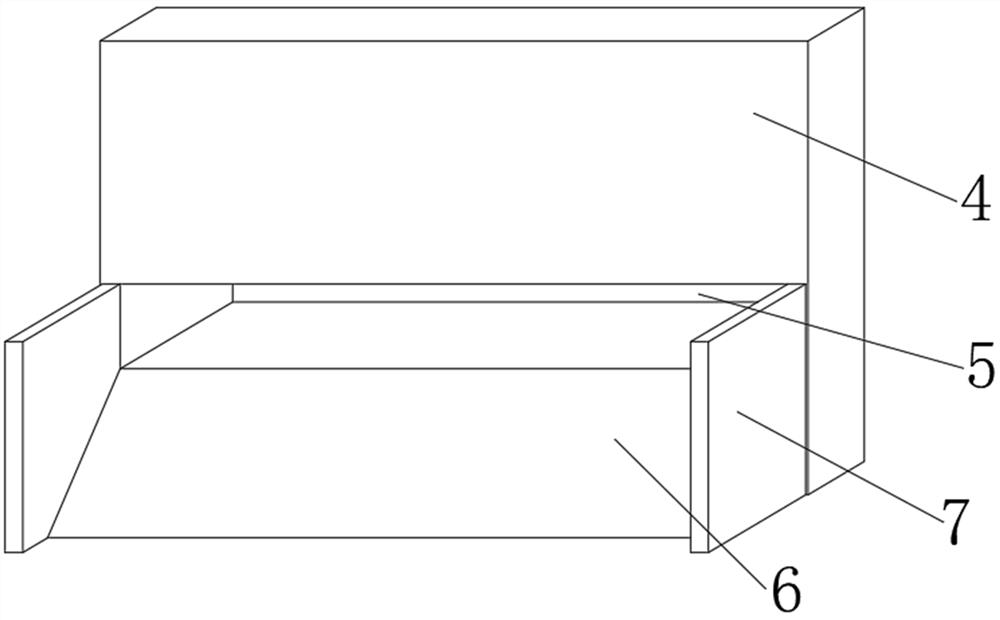

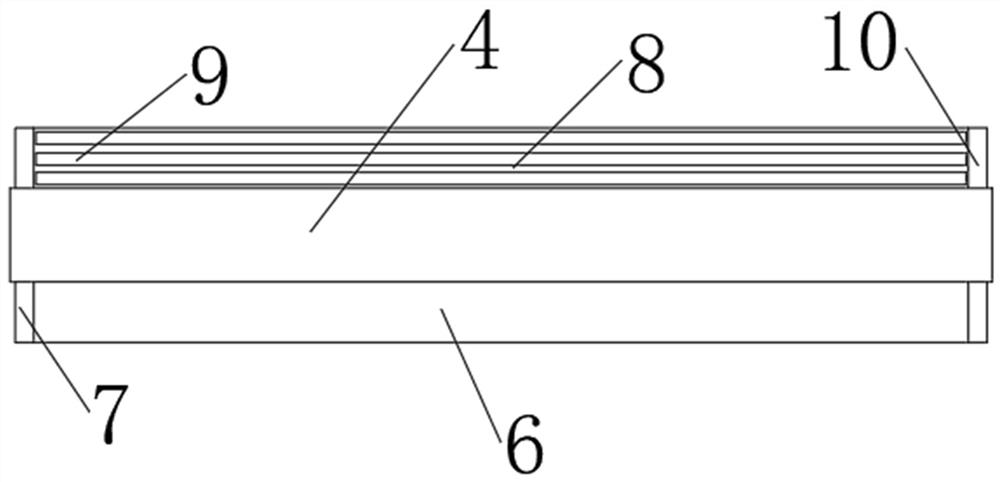

[0031] Such as Figure 1-6As shown, a plastic bottle recovery and separation device includes a sorting box (1) and a separation box (11). Several output channels (2) are opened below the interior of the sorting box (1), and the interior of the output channel (2) is provided with Conveying slide rails (3), a push plate (4) is arranged in the finishing box (1), and a through hole (5) is opened under the push plate (4), and the top of the side of the push plate (4) is connected with the finishing box (1) The inner walls are connected by telescopic rods, a separation box (11) is provided under the side of the finishing box (1), a first slope (6) is provided under the side of the push plate (4), and the first slope (6) A first side plate (7) is provided at both ends, a second slope (8) is provided under the other side of the push plate (4), and a second side plate (10) is provided at both ends of the second slope (8), Conveying rollers (9) are provided on the other side of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com