Water-based metal processing cutting fluid for steel and aluminum and preparation method thereof

A technology of base metal and cutting fluid, which is applied in the field of steel-aluminum and water-based metal processing cutting fluid and its preparation, can solve the problem that the cutting fluid is difficult to meet the processing needs of steel and aluminum alloy at the same time, and achieve good economic and environmental benefits. , Wide range of applications, suitable for market applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

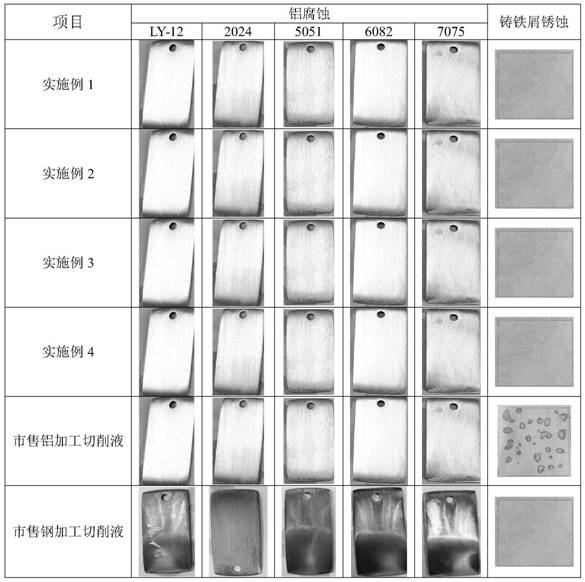

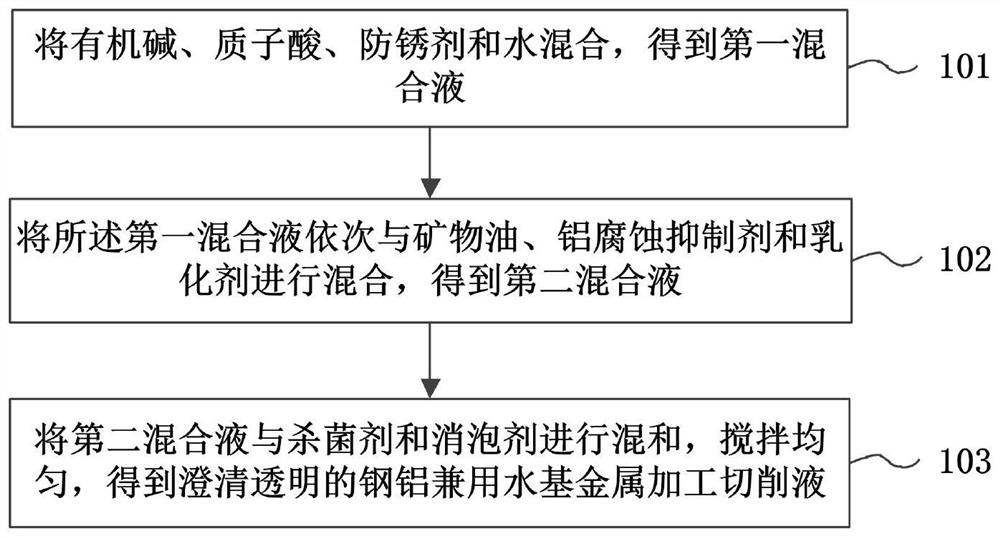

[0037] refer to figure 1As shown in the work flow chart, the application provides a method for preparing aluminum and water-based metalworking cutting fluid, comprising the following steps:

[0038] Step 101, mixing organic base, protonic acid, antirust agent and water to obtain a first mixed solution;

[0039] Step 102, mixing the first mixed solution with mineral oil, aluminum corrosion inhibitor and emulsifier in sequence to obtain a second mixed solution;

[0040] Step 103, mixing the second mixed liquid with the bactericide and defoamer, and stirring evenly to obtain a clear and transparent water-based cutting fluid for steel and aluminum combined.

[0041] In the above-mentioned cutting fluid preparation process, the mixing in the step is preferably carried out under stirring conditions, and the mixing temperature is only at room temperature, and the operation of step 102 can only be performed after the solid raw materials are completely dissolved in step 101, and the s...

Embodiment 1

[0044] Preparation of cutting fluid: mix organic base, protonic acid, antirust agent and water according to the information of each component in Table 1 to obtain the first mixed solution; mix the first mixed solution with mineral oil, aluminum corrosion inhibitor and The emulsifier is mixed to obtain a second mixed liquid; the second mixed liquid is mixed with a bactericide and a defoamer, and stirred evenly to obtain a clear and transparent water-based metal processing cutting fluid for steel and aluminum.

[0045] Each component information of table 1 embodiment 1

[0046]

[0047]

Embodiment 2

[0049] Preparation of cutting fluid: mix organic base, protonic acid, antirust agent and water according to the information of each component in Table 2 to obtain the first mixed solution; mix the first mixed solution with mineral oil, aluminum corrosion inhibitor and The emulsifier is mixed to obtain a second mixed liquid; the second mixed liquid is mixed with a bactericide and a defoamer, and stirred evenly to obtain a clear and transparent water-based metal processing cutting fluid for steel and aluminum.

[0050] Each component information of table 2 embodiment 2

[0051] name weight specific information type hydrogenated mineral oil 16kg commercially available mineral oil Tribasic Organic Phosphonates 1kg commercially available Rust inhibitor Alcoholamine 6kg commercially available organic base Alicyclic amine 2kg commercially available organic base Ether Nonionic Surfactant 4kg commercially available E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com