Explosion arrestment wall internally provided with multi-spindle type pressure relief cavitie

A technology of pressure relief cavity and spindle, which is applied in the field of explosion-proof walls, can solve huge and other problems, and achieve the effects of high-efficiency resistance to explosion impact, improved explosion-proof and fire-proof performance, and strong anti-crack and explosion-proof capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

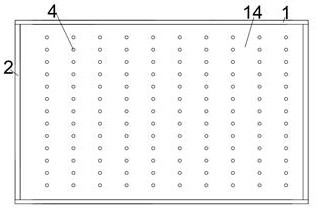

[0026] A kind of explosion-proof wall with built-in multi-spindle pressure relief chamber, such as Figure 1~Figure 4As shown, it mainly includes end sealing plate 1, side vertical sealing plate 2, rear panel 3, rear plate pressure relief and energy absorption hole 4, front panel 5, front plate pressure relief and energy absorption hole 6, built-in explosion-proof fiber concrete 7, front Discharge pressure-absorbing spindle cavity 8, rear discharge pressure-absorbing spindle cavity 9, front explosion-proof reinforced fiber mesh 10, rear explosion-proof reinforced fiber mesh 11, shock-absorbing and fire-resistant filler 12, elastic cushioning soft rubber partition 13 And anti-crack and anti-seepage elastic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com