Method for determining unsteady flow bottom hole pressure of fractured well in dense oil reservoir

A bottom-hole pressure, tight oil reservoir technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc. speed, reduced performance requirements, and the effect of increasing computational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

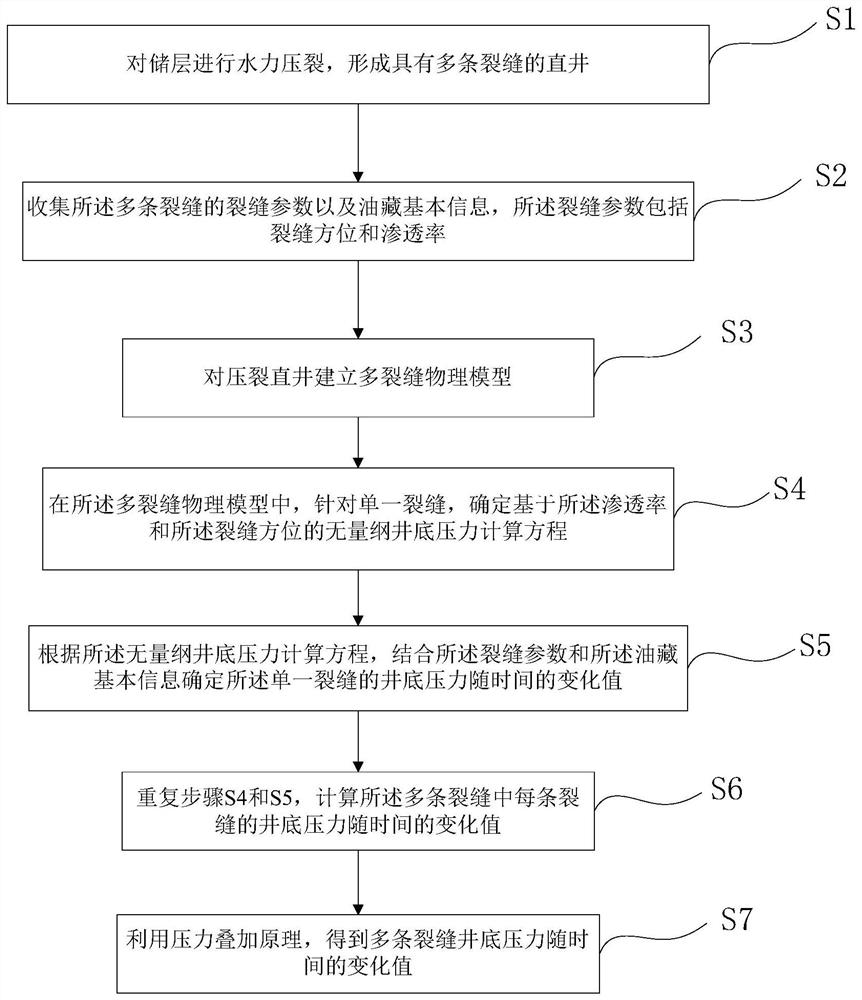

[0057] figure 1 A method for determining the unsteady constant flow bottomhole pressure of fracturing wells in tight oil reservoirs according to the present invention is shown, and the processing method comprises the following steps:

[0058] S1. Perform hydraulic fracturing on the reservoir to form a vertical well with multiple fractures;

[0059] S2. Collect the fracture parameters of multiple fractures and the basic information of the reservoir. The fracture parameters include fracture orientation and permeability;

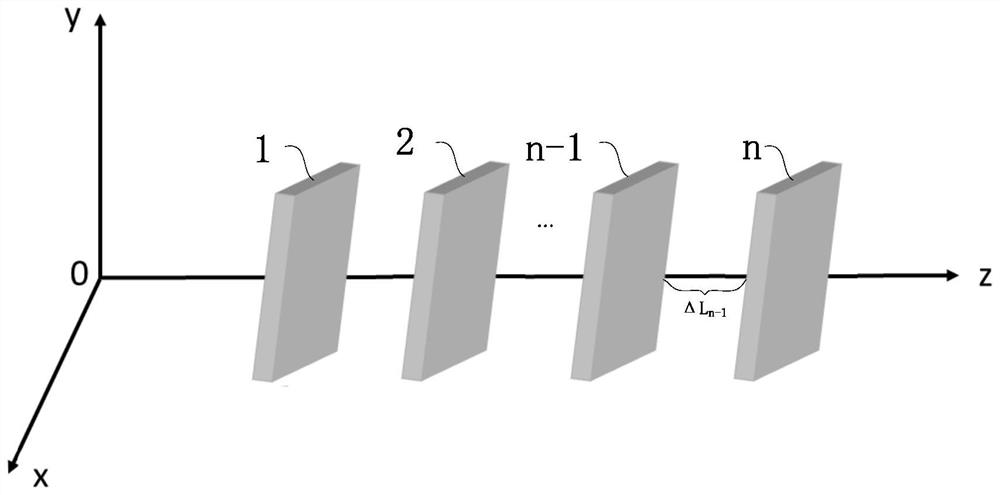

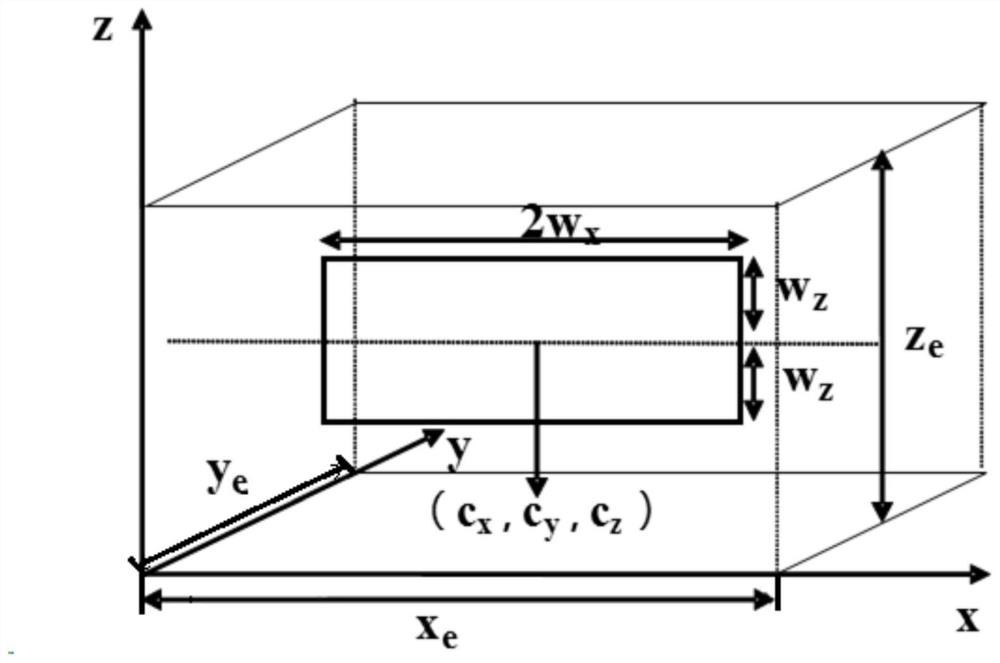

[0060] S3. Establish a multi-fracture physical model for the fracturing vertical well;

[0061] S4. In the multi-fracture physical model, for a single fracture, determine the dimensionless bottom hole pressure calculation equation based on the permeability and the orientation of the fracture;

[0062] S5. According to the dimensionless bottom hole pressure calculation equation, combined with the fracture parameters and the basic information of the reservoir, ...

Embodiment 2

[0135] This example provides an application method for calculating and optimizing the bottom hole pressure of tight oil reservoirs. A tight fracturing production well in the Chang 812 reservoir of Jinghe Oilfield is selected. The reservoir parameters and production data are shown in Table 3 and Table 4. Show. Below in conjunction with the steps of the present invention, carry out the detailed introduction of bottomhole pressure optimization application, the steps are as follows:

[0136] (1) Through the crack monitoring data, collect the relevant parameters of the crack, such as the crack orientation, the length, width and height of the crack, and the number of cracks;

[0137] (2), collect the basic information of the oil reservoir, the specific parameters are shown in Table 3;

[0138] (3), according to step S1-S4 of the present invention can obtain bottom hole pressure variation equation with time under the single fracture:

[0139] P D represents the dimensionless sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com