Petrochemical waste heat recovery device

A waste heat recovery device and petrochemical technology, which is applied in the field of chemical manufacturing to achieve the effects of high degree of automation, safe use and accelerated adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

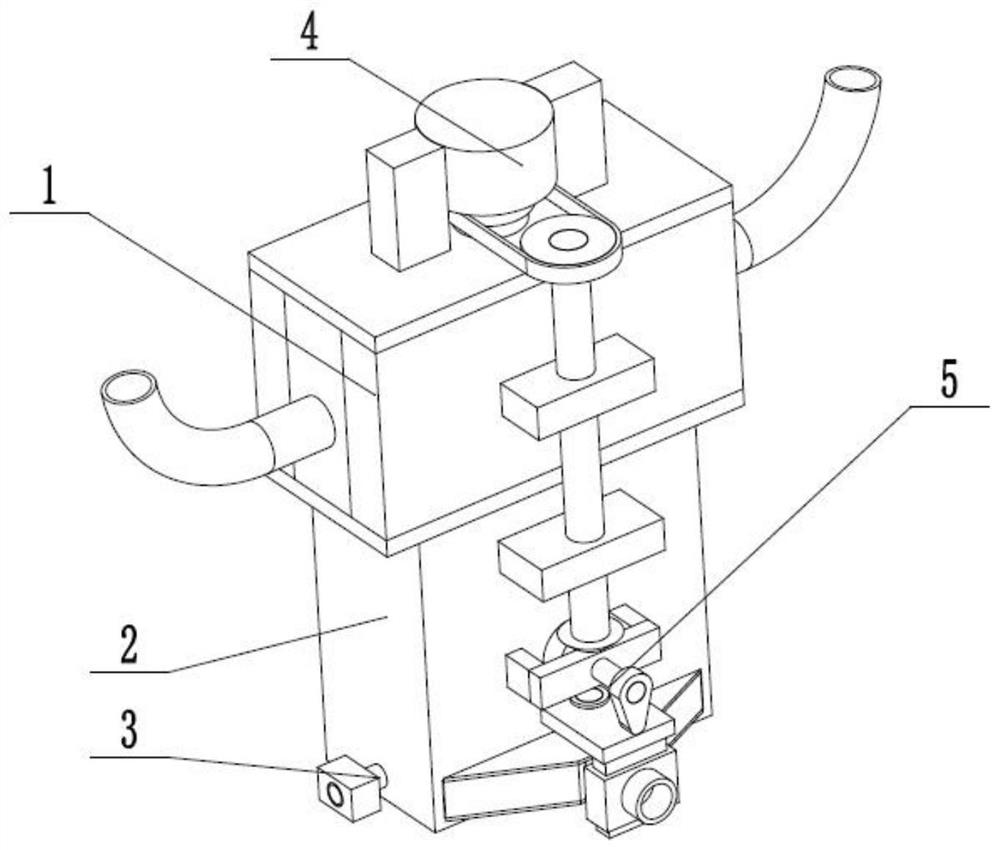

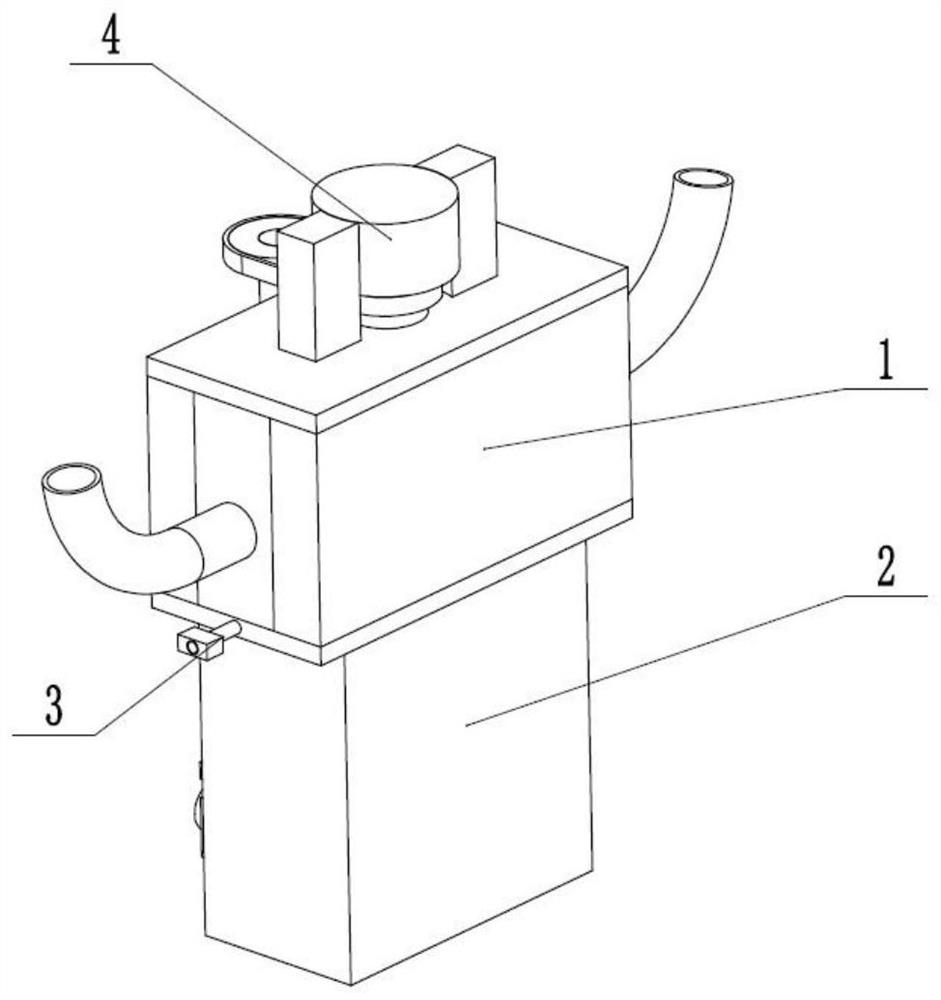

[0029] like Figure 1 to Figure 9 As shown, a petrochemical waste heat recovery device includes a waste heat recovery frame 1, a sealed waste heat absorption frame 2, a heat recovery device 3, a stable pressurized heat absorber 4 and a linkage pressure bearing valve 5. The waste heat recovery frame 1 It is fixedly connected and communicated with the upper end of the sealed waste heat absorption frame 2, the heat recovery device 3 is fixedly connected in the sealed waste heat absorption frame 2, and the stable pressurized heat absorber 4 is rotatably connected in the waste heat recovery frame 1 to stably pressurize and absorb heat The device 4 is linked with the pressure-bearing valve 5 through the meshing transmission connection. By continuously adding hot air with waste heat into the waste heat recovery frame 1, the hot air flows through the sealed waste heat absorption frame 2 and the heat recovery device 3, and the heat recovery device 3 absorbs heat and is discharged. Und...

specific Embodiment approach 2

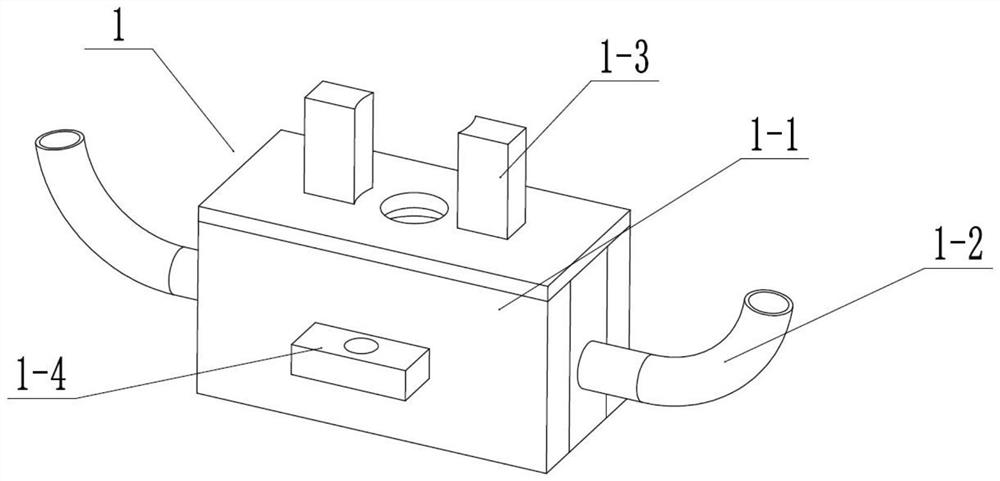

[0031] like Figure 1 to Figure 9As shown, this embodiment further explains Embodiment 1. The waste heat recovery frame 1 includes a recovery frame 1-1, two waste heat addition pipes 1-2, a motor fixing seat 1-3, a fixed rotating seat 1-4, Two spacers 1-5, two sliding extrusion slots 1-6, two side chute 1-7, four fixed sliding shafts 1-8 and four springs 1-9, recovery frame 1-1 The two ends are respectively fixedly connected and communicated with two waste heat adding pipes 1-2, the motor fixing base 1-3 is fixedly connected to the upper end of the recovery frame 1-1, and the fixed rotating base 1-4 is fixedly connected to the rear end of the recovery frame 1-1 , the two spacers 1-5 are fixedly connected to the inner wall of the recovery frame 1-1, the two spacers 1-5 are provided with sliding extrusion slots 1-6, and the two side slide grooves 1-7 are respectively provided At both ends of the recovery frame 1-1, two side chutes 1-7 are respectively connected to two waste hea...

specific Embodiment approach 3

[0033] like Figure 1 to Figure 9 As shown, this embodiment further describes Embodiment 2. The sealed waste heat absorption frame 2 includes a sealed pressure-bearing frame 2-1, a fixed frame 2-2, a conical collection and discharge frame 2-3, and a discharge pipe 2. -4 and the fixed sealing sliding frame 2-5, the sealing pressure bearing frame 2-1 is fixedly connected to the lower end of the recovery frame 1-1, the fixed frame 2-2 is fixedly connected to the rear end of the sealing pressure bearing frame 2-1, tapered The collection and discharge frame 2-3 is fixedly connected and communicated with the lower side of the rear end of the sealed pressure-bearing frame 2-1, the discharge pipe 2-4 is fixedly connected and communicated with the conical collection and discharge frame 2-3, and the discharge pipe 2-4 is fixedly connected And communicate with fixed sealing sliding frame 2-5. The gas is easily collected in the conical collection and discharge frame 2-3 and discharged th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com