Engineering quality supervision system

A monitoring system and engineering quality technology, applied in the field of engineering inspection, can solve problems such as inability to clearly and intuitively display inspection results, inability to realize construction quality supervision, inability to feed back inspection results to supervisors, etc., to achieve information management and remote monitoring The effect of supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

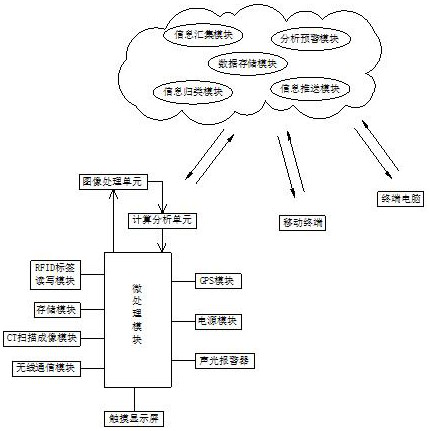

[0022] refer to figure 1 and figure 2 , an engineering quality supervision system, including an on-site detection terminal, a supervision platform and a receiving terminal.

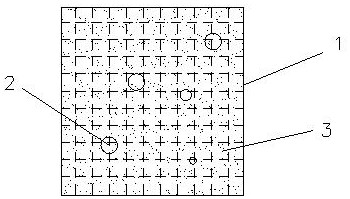

[0023] The on-site detection terminal includes a micro-processing module, a CT scanning imaging module, a GPS module, a wireless communication module, an alarm module, a storage module, a touch screen and a power supply module. The micro-processing module is used for computing, processing, sending and receiving and processing instructions on the data; the data port of the CT scanning imaging module is connected to the port of the micro-processing module, and the CT scanning imaging module is used for scanning and imaging the local area of the concrete pouring body; GPS The module is connected to the data port of the micro-processing module, and the GPS module is used for geographic positioning; the wireless communication module is connected to the command port of the micro-processing module, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com