Processing method for nickel gold immersion at bottom of PCB step groove

A processing method, immersion nickel-gold technology, applied in the field of immersion nickel-gold at the bottom of PCB step grooves, can solve problems such as unsatisfactory, achieve mass production and avoid glue residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

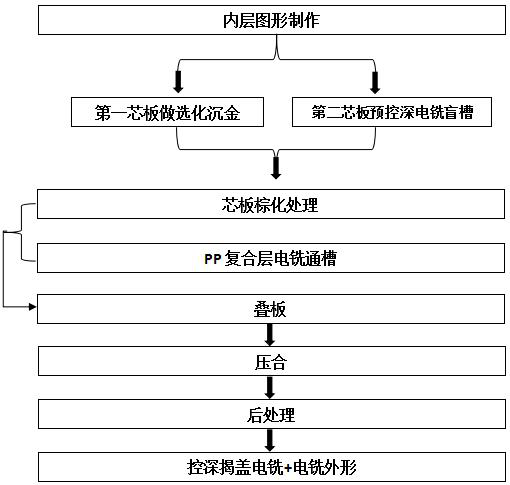

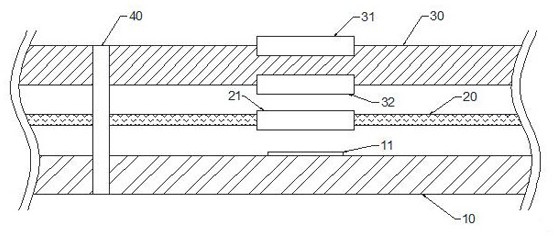

[0014] In the processing method for making the bottom of the PCB step groove as immersion nickel gold according to the present invention, before the multi-layer board is pressed, the first core board corresponding to the bottom of the step groove is first selected for immersion nickel gold, and the second core board corresponding to the step groove body is first selected. The core board is mirrored and pre-controlled deep electric milling blind grooves, and at the same time, PP with low flow glue is prepared, and the electric milling through grooves are first positioned to obtain the PP composite layer. Then, lamination is carried out, and a PP composite layer is placed between the first core board and the second core board, and is produced according to the conventional process after pressing. After the surface treatment is done, control the depth and uncover the cover and conduct electric milling and electric milling. The final product forms a step groove, and realizes the PAD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com