Manufacturing method of microfluidic actuator module

A manufacturing method and actuator technology, applied in the direction of electric solid devices, semiconductor devices, fluid velocity measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Embodiments embodying the features and advantages of this case will be described in detail in the description of the latter paragraph. It should be understood that the present case can have various changes in different aspects without departing from the scope of the present case, and the descriptions and diagrams therein are used for illustration in nature rather than limiting the present case.

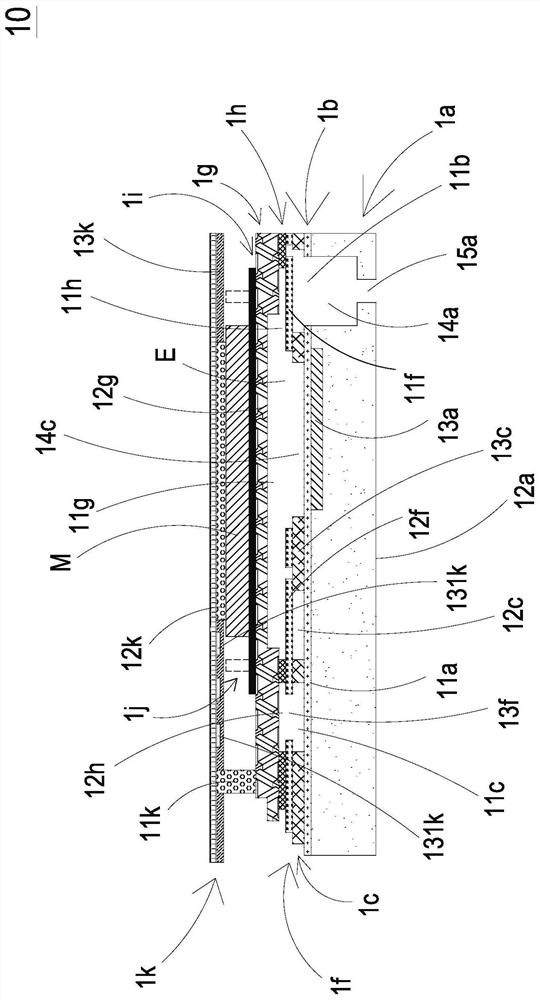

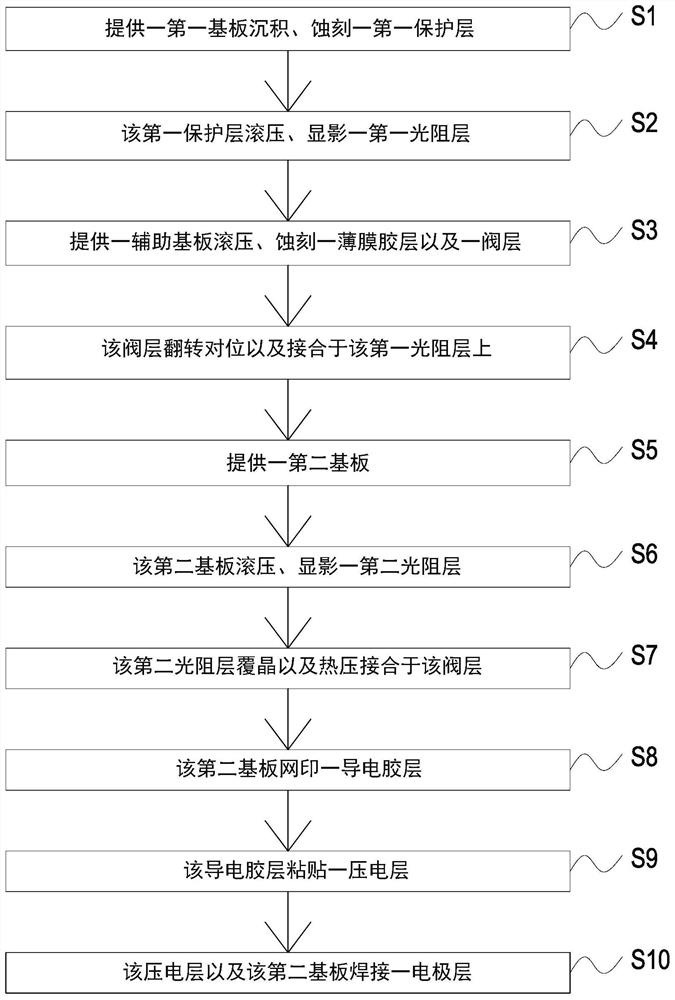

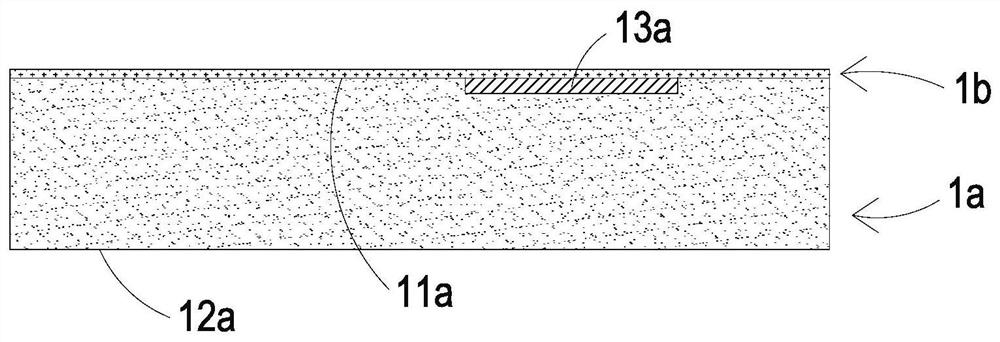

[0070] The microfluidic actuators in this case are used to transport fluids, see figure 1 as well as Figure 4 , in the embodiment of this case, the microfluidic actuator module 100 includes a plurality of microfluidic actuators 10, and consists of a first substrate 1a, a first protective layer 1b, a first photoresist layer 1c, an auxiliary substrate 1d (as shown in Figure 2H to Figure 2J), a film adhesive layer 1e (as shown in Figure 2H to Figure 2J), a valve layer 1f, a second substrate 1g, a second photoresist layer 1h, and a conductive adhesive layer 1i, a piezoelectric l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com