A thick-gauge pipeline steel and its low compression ratio production process

A technology with low compression ratio and thick specifications, which is applied in the field of low-carbon micro-alloy steel materials, can solve the problems that the drop hammer toughness cannot meet the standard requirements, segregation and porosity in the core of continuous casting slabs, and easy coarse grains, etc. The effect of solving the macro segregation problem, improving the matching of strength and toughness, and reducing the purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

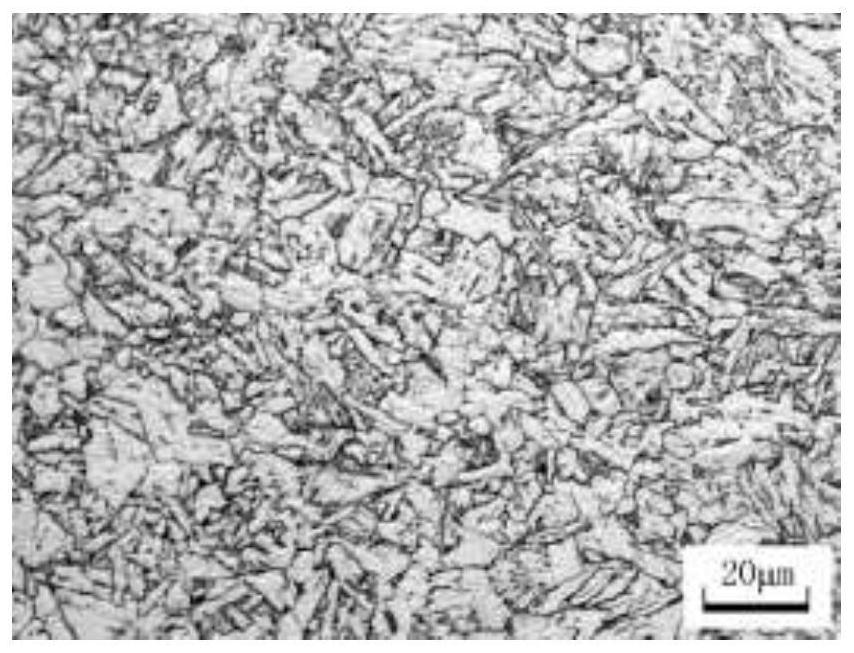

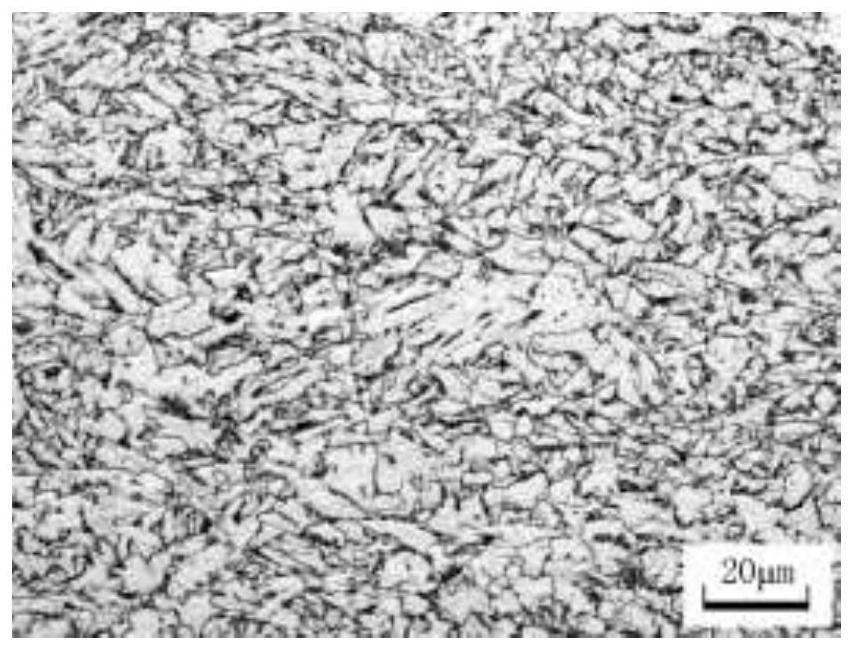

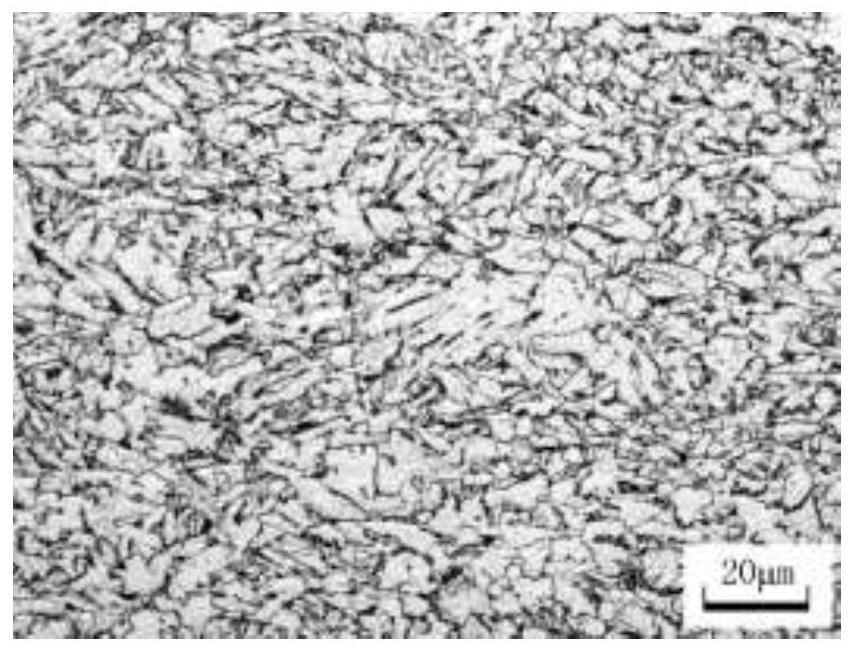

Image

Examples

Embodiment 1~4

[0052] 150mm billet is used to roll 25mm thickness X70 grade seabed acid-resistant pipeline steel. The specific implementation steps are as follows:

[0053] 1) Carry out smelting according to the composition requirements stated in Table 1, and control the content of molten steel as follows: N≤0.0050%, H≤0.0002%, O≤0.0025%, P≤0.015%, S≤0.0030%; molten steel composition After qualified, the molten steel is treated with Mg, the Mg in the molten steel is controlled at 0.0002-0.0022%, and the casting temperature is controlled at 1533-1548°C. At the same time, electromagnetic stirring and light reduction technology are used during the continuous casting solidification process to reduce the composition and Organization macro segregation;

[0054] 2) After casting a slab with a thickness of 150mm, install a heating furnace to heat and keep it warm; the heating temperature is 1160-1200°C; according to different furnace loading temperatures, the time in the furnace is 130-230min, and t...

Embodiment 5~9

[0066] Using 230mm billet to roll 40mm-41mmX70 grade pipeline steel, the specific implementation steps are as follows:

[0067] 1) Carry out smelting according to the composition requirements stated in Table 4, and control the content of molten steel as follows: N≤0.0050%, H≤0.0002%, O≤0.0025%, P≤0.015%, S≤0.0030%; molten steel composition After the molten steel composition is qualified, the molten steel is treated with Mg, the Mg in the molten steel is controlled at 0.0002-0.0022%, and the temperature is controlled at 1533-1548°C during casting. Reduce the composition and macro-segregation of the slab;

[0068] 2) After casting into a slab with a thickness of 230mm, install a heating furnace to heat and keep it warm; the heating temperature is 1160-1200°C; according to different furnace loading temperatures, the time in the furnace is 160-260min, and the holding time at a high temperature of 1160-1200°C is 60-100min;

[0069] 3) Three-stage hot rolling; in the first stage, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com