A kind of low-carbon martensitic steel, 10,000-meter drilling rig lifting ring and preparation method thereof

A technology of martensitic steel and lifting rings, which is applied to drilling equipment, drill pipes, drill pipes, etc., can solve problems such as failure to meet the use requirements, reduce the formation of inclusions and harmful tissues, improve hardenability, and shorten the manufacturing cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

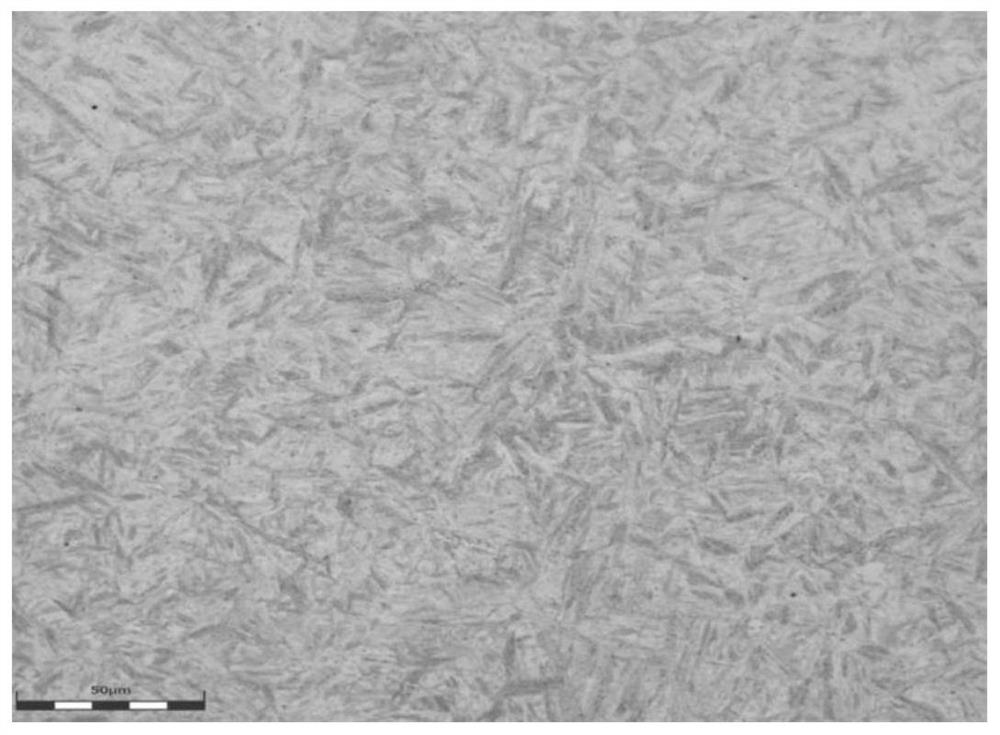

[0034] The preparation method of suspension ring of the present invention specifically comprises the following steps:

[0035] (1) Refined into billet according to the following composition, its composition is calculated by mass percentage, including the following components:

[0036] C: 0.17% to 0.19%; Si: 0.20% to 0.25%; Mn: 0.6% to 0.7%; Cr: 1.5% to 1.6%; Mo: 0.7% to 0.8%; Ni: 4.1% to 4.3%; V: 0.13%~0.15%; S≤0.005% and P≤0.01%, the rest is iron and unavoidable impurities.

[0037](2) Electroslag remelting is performed on the steel billet to obtain an ingot with a diameter of not less than 690mm, the ingot is heated evenly, the heating temperature is controlled at 1180±10°C, and forging is carried out, and the termination temperature of forging is controlled above 860°C to obtain Round steel with a diameter of 350mm to 380mm shall be annealed at no lower than 400°C after forging to eliminate forging defects and residual stress;

[0038] (3) Heat the round steel to 1180±10°...

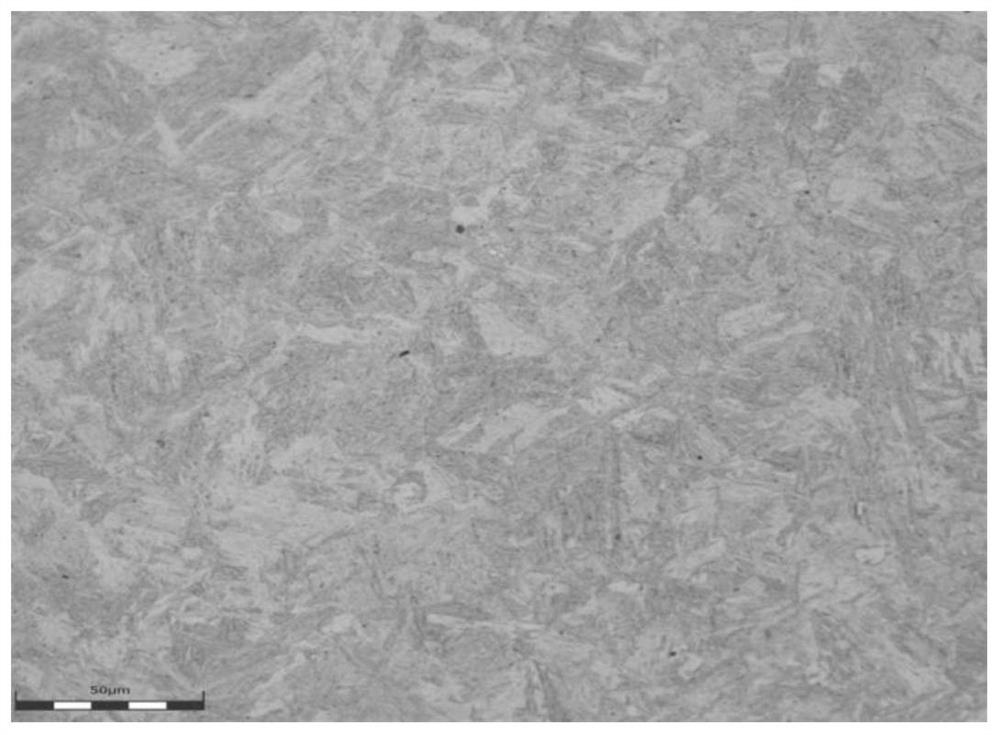

Embodiment 1

[0042] The invention discloses a preparation method of a suspension ring, which specifically comprises the following steps:

[0043] (1) as shown in table 1, carry out refining into billet according to following composition, and its composition is calculated by mass percentage, comprises following component:

[0044] C: 0.17%; Si: 0.20%; Mn: 0.6%; Cr: 1.5%; Mo: 0.7%; Ni: 4.1%; Avoid impurities.

[0045] (2) Electroslag remelting is performed on the steel billet to obtain an ingot with a diameter of 690mm. The ingot is heated evenly to 1170°C for forging. The forging temperature is controlled at 860°C to 1170°C to obtain a circle with a diameter of 350mm to 360mm. For steel, after forging, the surface temperature is lowered to 400°C and annealed in the furnace;

[0046] (4) The round steel is reheated to 1170°C for forging, the forging temperature is controlled at 860°C to 1170°C, and a suspension ring sample with a diameter of 160mm is obtained by forging;

[0047] (5) Heat...

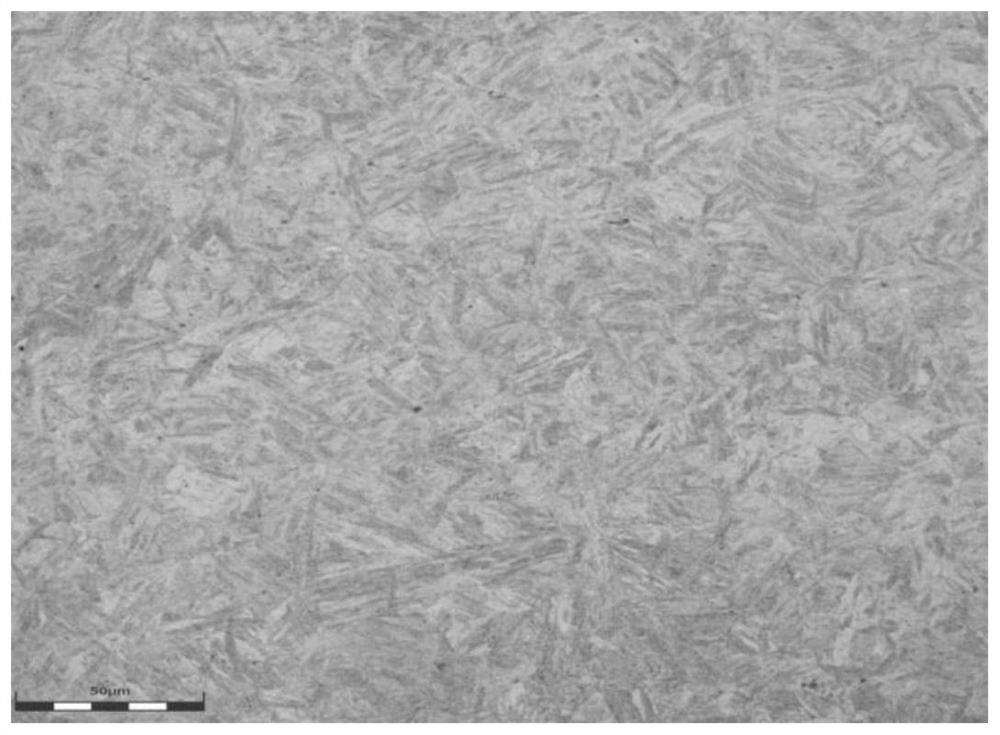

Embodiment 2

[0050] The invention discloses a preparation method of a suspension ring, which specifically comprises the following steps:

[0051] (1) as shown in table 1, carry out refining into billet according to following composition, and its composition is calculated by mass percentage, comprises following component:

[0052] C: 0.19%; Si: 0.25%; Mn: 0.7%; Cr: 1.6%; Mo: 0.8%; Ni: 4.3%; V: 0.15%; Avoid impurities.

[0053] (2) Electroslag remelting is performed on the steel billet to obtain an ingot with a diameter of 870mm, and the ingot is heated evenly to 1190°C for forging at a forging temperature of 860°C to 1170°C to obtain round steel with a diameter of 360mm to 380mm. After forging, the surface temperature is lowered to 450°C and annealed in the furnace;

[0054] (4) Reheat the round steel to 1190°C for forging, the forging start temperature is controlled at 860°C to 1170°C, and a ring sample with a diameter of 170mm is obtained by forging;

[0055] (5) Heat the suspension ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com