Shallow subgrade construction equipment and construction method

A technology for construction equipment and roadbed, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inability to guarantee the construction quality of concrete at nodes, concrete quality accidents at nodes, waste of high-grade concrete, etc. Ensuring construction quality and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

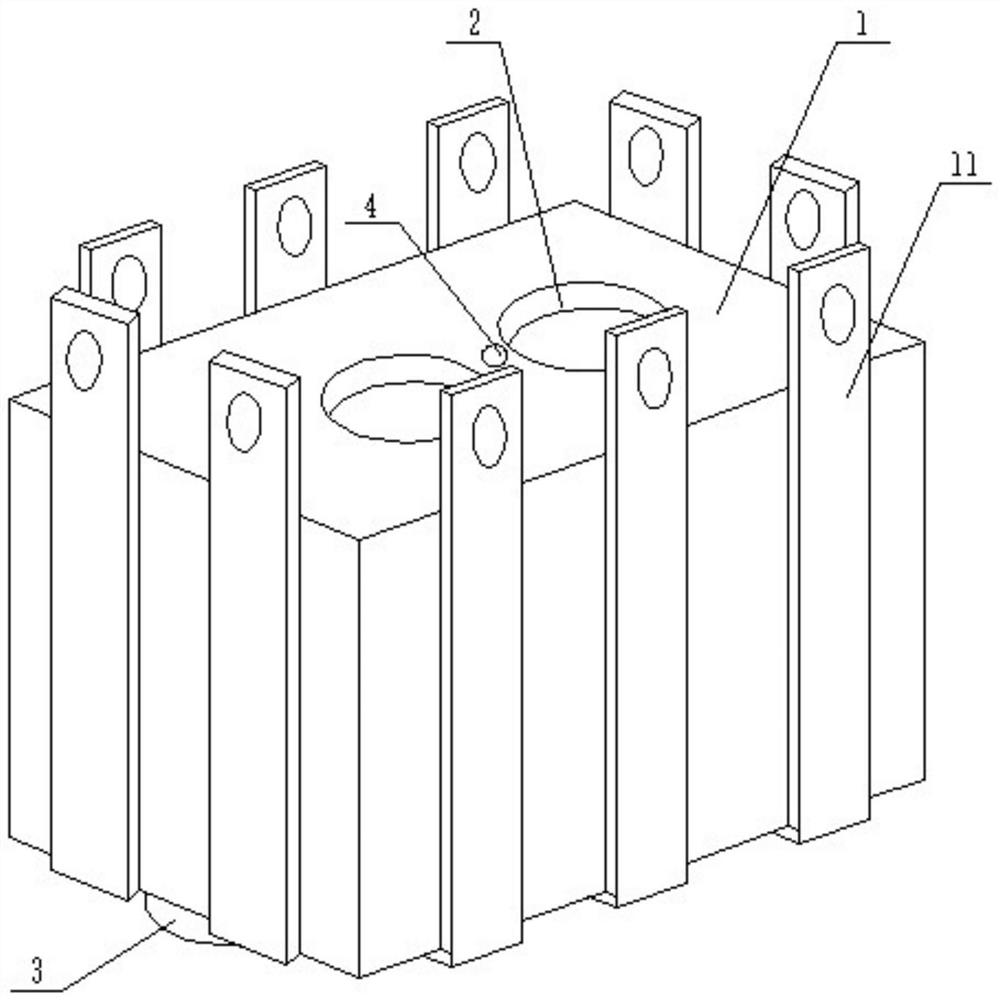

[0020] Embodiment 1 Shallow subgrade construction equipment

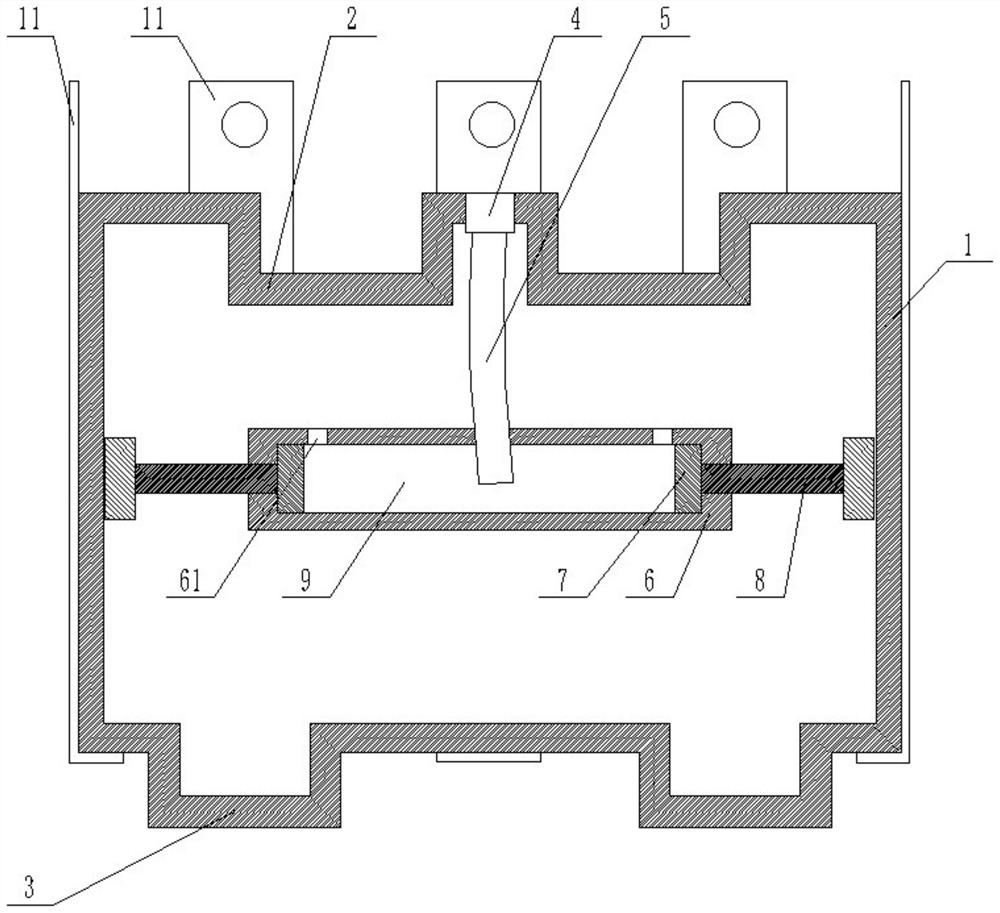

[0021] Shallow roadbed construction equipment, comprising a rectangular capsule 1, the rectangular capsule 1 includes an inner layer and an outer layer, the inner layer is a rubber layer, the outer layer is a reinforced protective layer of polyester fiber cloth, the inner layer and the outer layer are Hot press vulcanization treatment and cementation as a whole, one-time molding, inflation pressure can reach 0.03MPa, the center of the upper surface of the rectangular capsule 1 is provided with an airbag opening 4, and the upper surface of the rectangular capsule 1 is sunken inward to form an upper positioning area 2 , the lower surface of the rectangular capsule 1 protrudes outwards to form a lower positioning portion 3, there are two upper positioning areas 2 and two lower positioning portions 3, two upper positioning areas 2 and two The lower positioning parts 3 are arranged on both sides of the airbag opening 4, ...

Embodiment 2

[0022] The construction method of embodiment 2 shallow subgrade construction equipment

[0023] Include the following steps:

[0024] S1. Empty the gas in the rectangular capsule 1 before construction;

[0025] S2. According to the situation, multiple rectangular capsules 1 can be stacked, spliced and placed at the beam end section that needs to be isolated, and then start to inflate. During the inflation process, the gas enters the air chamber 9, and the horizontal strut 8 is pushed out, so that the corresponding The adjacent rectangular capsule 1 is pressed against and fixed, and after continuing to inflate to the specified pressure, the lower positioning part 3 of the rectangular capsule 1 above and the upper positioning area 2 of the rectangular capsule 1 below are snapped together to form a solidly fixed;

[0026] S3. Use the beam body stirrups, pull hooks and side formwork to pull the bolts to make the rectangular capsule body 1 closely adhere to the beam formwork to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com