Highway bridge pile foundation drilling device and using method thereof

A technology for drilling devices and highway bridges, which is applied in the direction of drilling equipment and methods, electromechanical devices, supporting devices, etc., which can solve problems such as falling into cavities, scattering, and affecting the effect of concrete pouring, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

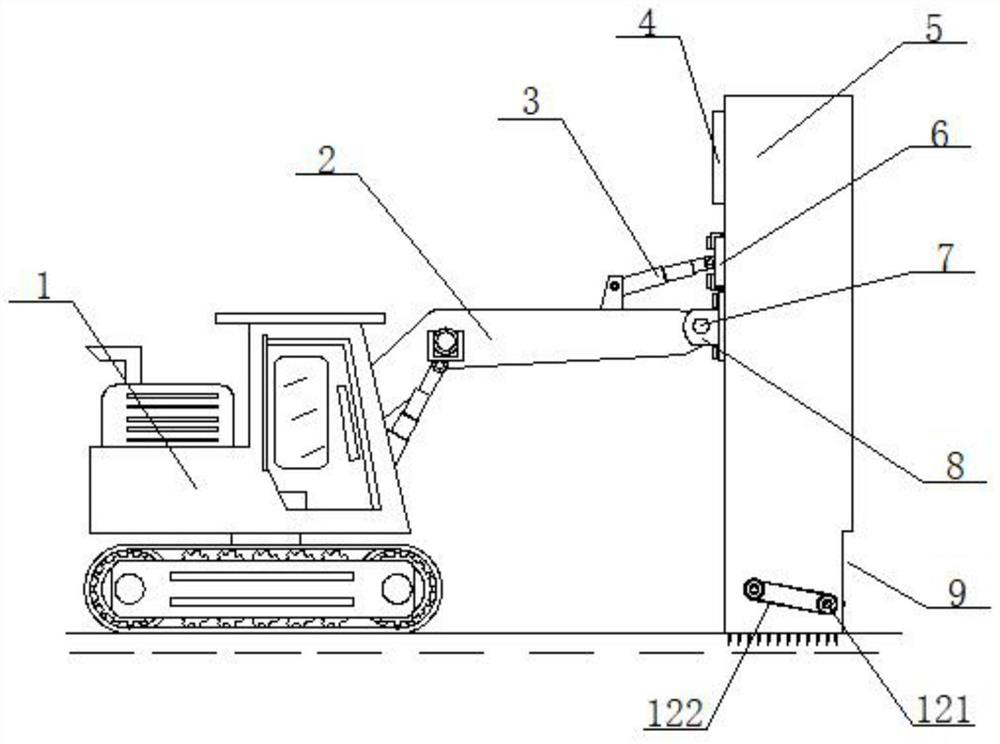

[0041] Example 1, such as figure 1 As shown, before drilling, the main body of the excavator 1 controls the opening of the mechanical arm 2 to a suitable angle, and then controls the extension of the telescopic hydraulic cylinder A3 to control the angle between the main body compartment 5 and the ground, and then controls the mechanical arm 2 Lower a little until the bottom of the main body compartment 5 is close to the ground, so that the main body compartment 5 is fixed on the ground at an appropriate angle, and then the ground is drilled through the drilling holes inside the main body compartment 5 .

Embodiment 2

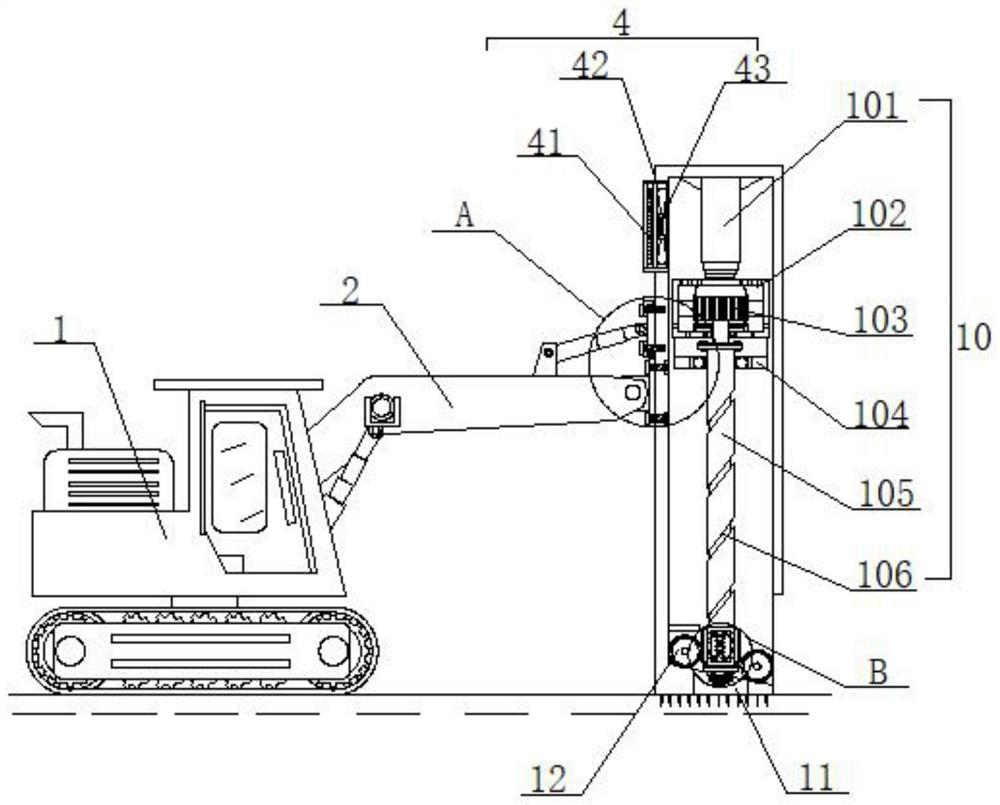

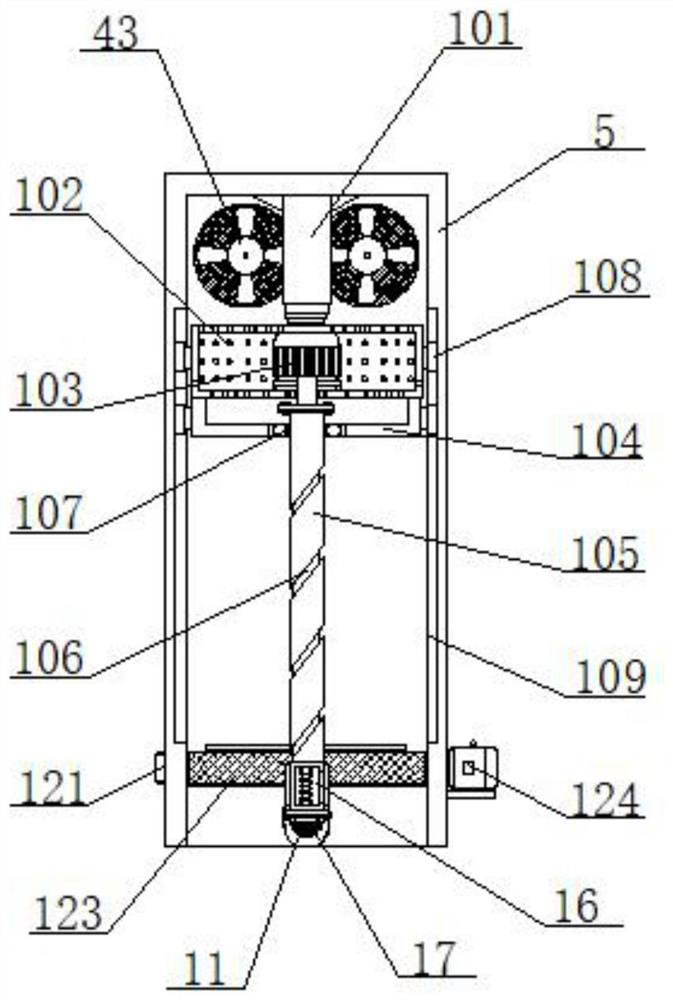

[0042] Example 2, such as figure 2 , 3 , 4 and 5, when starting to drill, the control panel on the excavator main body 1 controls the drive motor 103 to rotate, and the drive motor 103 drives the rotating rod 105 to rotate together, thereby driving the compact hole wall assembly 16 and the drill bit 17 Rotate, then control the telescopic hydraulic cylinder B101 to gradually extend, the drill bit 17 passes through the through groove 11 and starts to drill holes on the ground, the soil generated by the drilling is discharged to the inside of the main body compartment 5 along the spiral groove 106, and then the rotating motor 124 is controlled Rotate, because the two groups of guide rollers 123 are driven and connected by the cooperation of the pulley 121 and the transmission belt 122, the rotating motor 124 will drive the two groups of guide rollers 123 to rotate synchronously, so that the soil that will enter the bottom of the main body compartment 5 will gradually flow from t...

Embodiment 3

[0043] Example 3, such as figure 2 , 3 , 6 and 7, when the hole of the pile foundation is drilled, the driving motor 103 is controlled to speed up the speed greatly, thereby driving the installation warehouse 161 to rotate at an accelerated speed. The two sets of semi-arc scrapers 164 are opened outside the installation chamber 161, the two sets of sliding blocks 163 are close to each other, the spring 162 is shortened by force, and then the telescopic hydraulic cylinder B101 is controlled to shorten slowly, and the two sets of half-arcs rotated during the process The outside of the shaped scraper 164 constantly squeezes and polishes the inner wall of the hole. When the drill bit 17 is completely moved out of the hole, the driving motor 103 is controlled to stop rotating. 164 is tightly attached to the outside of the installation storehouse 161 again, and the inner wall of the hole has been compacted by the semi-arc scraper 164, so that no earth will fall into the hole on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com