Method for determining content of non-metallic elements in crude lead

A technology of non-metallic elements and determination methods, which is applied in the field of determination of non-metallic element content in crude lead, can solve the problems of easily divergent detection results, low detection accuracy of crude lead and lead slag, etc., and achieve high detection accuracy and simple principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

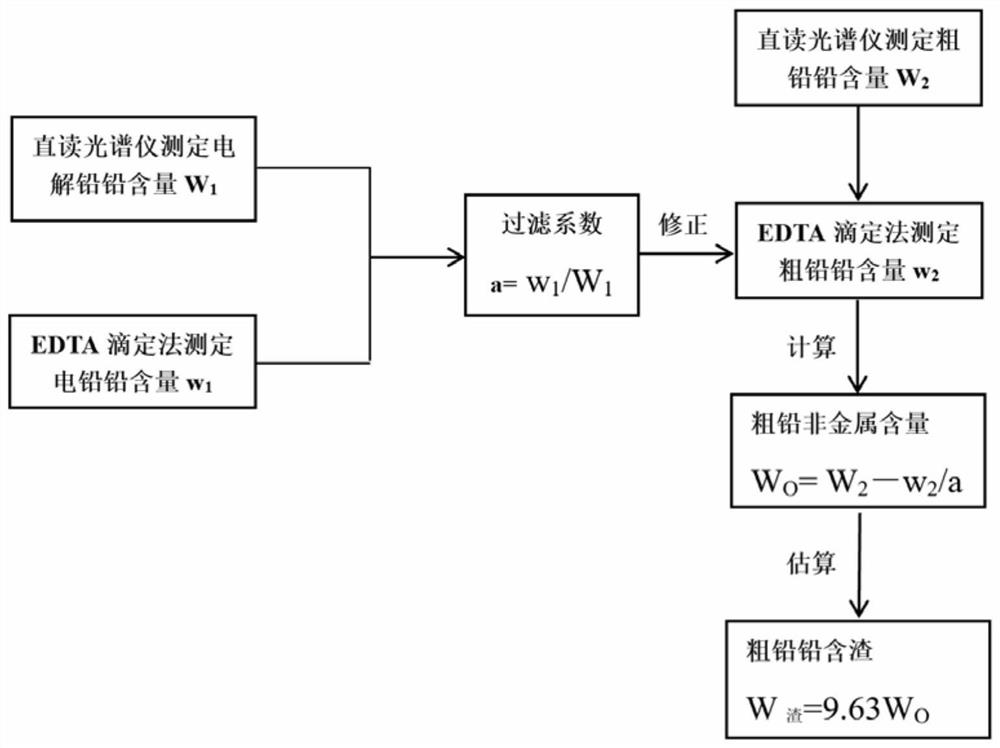

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

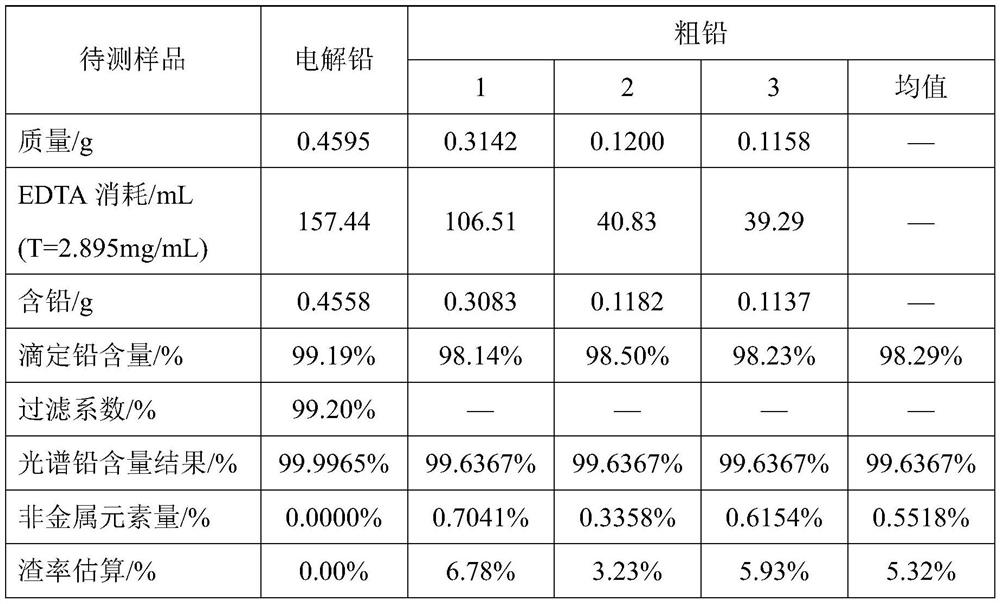

[0020] 1. Take a total of about 200g samples from different positions of crude lead, and melt and cast them into ingots in lead molds. After cooling, use a lathe to turn out a smooth plane, detect all elements in a direct-reading spectrometer, and take the same detection operation for electrolytic lead;

[0021] 2. Use a knife to cut about 0.1g (accurate to 0.0001g) sample from the crude lead ingot, put it into a beaker, digest it with nitric acid, and steam until it is nearly dry; add sulfuric acid and continue steaming until a large amount of white smoke comes out, stop heating, and cool down; Add 30mL of distilled water to the wall of the cup, boil and cool. Then filter with filter paper, wash the precipitate with distilled water, then transfer the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com