Surface leakage wave ultrasonic synthetic aperture focusing imaging method

A technology of synthetic aperture focusing and focusing imaging, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and re-radiation of sonic waves, etc. It can solve the problem of failure to detect defect features and low detection efficiency. , Failure to realize detection imaging and other problems, to achieve the effect of improving detection efficiency and imaging resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

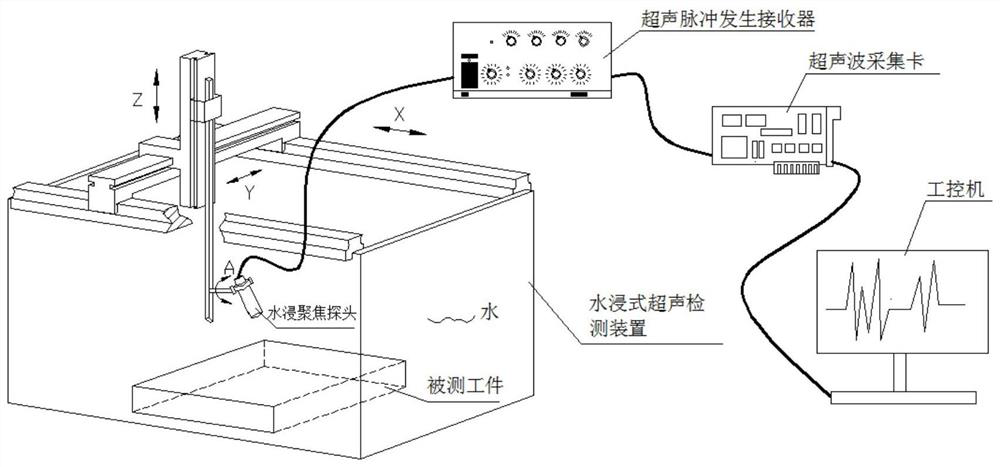

[0031] The experimental system of the present invention is composed of a mechanical motion control device, an ultrasonic pulse generating receiver, a water immersion focusing probe, an ultrasonic acquisition card and a workpiece to be tested, and 10 linearly distributed drilled steel test blocks with a diameter of 1mm are selected as the workpiece to be tested , the distance between the two holes is about 2mm, and the measured workpiece size is 120mm×100mm.

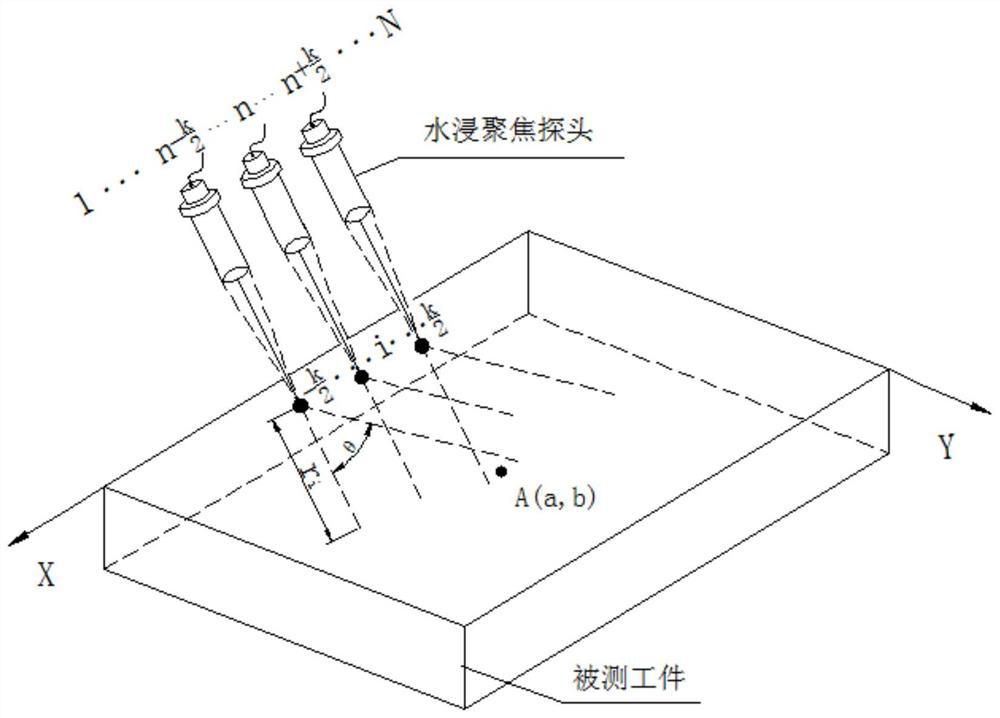

[0032] The steps of performing leaky surface wave ultrasonic synthetic aperture focusing imaging on the workpiece surface detection area include:

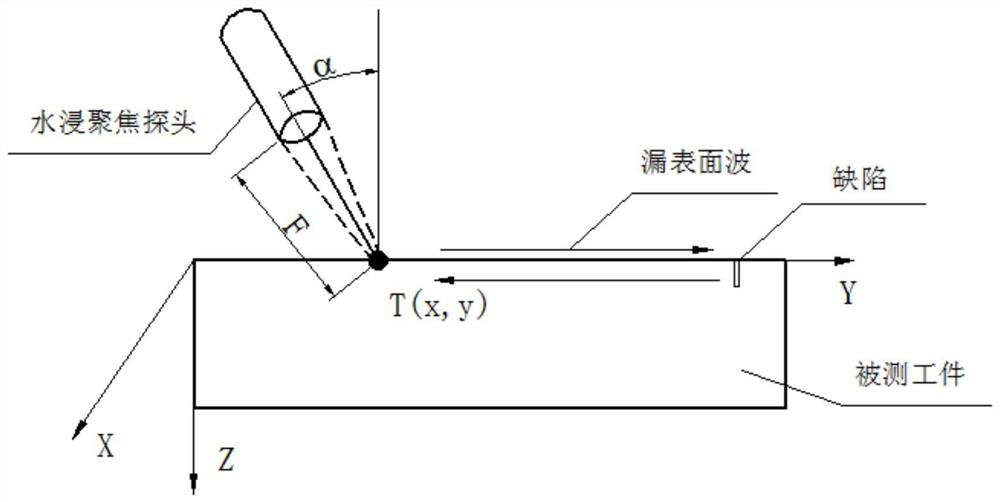

[0033] Step 1. Place the workpiece to be tested in the water tank of the water immersion ultrasonic testing device with X / Y / Z / A four-axis motion control. According to the acoustic characteristics of the workpiece and water to be tested, use Snell's law to determine the water immersion Rayleigh angle α during detection R , where c l is the propagation speed of longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com