Breathing machine

A ventilator and airbag technology, applied in the field of respiratory system, can solve the problems of high cost of oxygen supplementation, inability to supply at any time, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

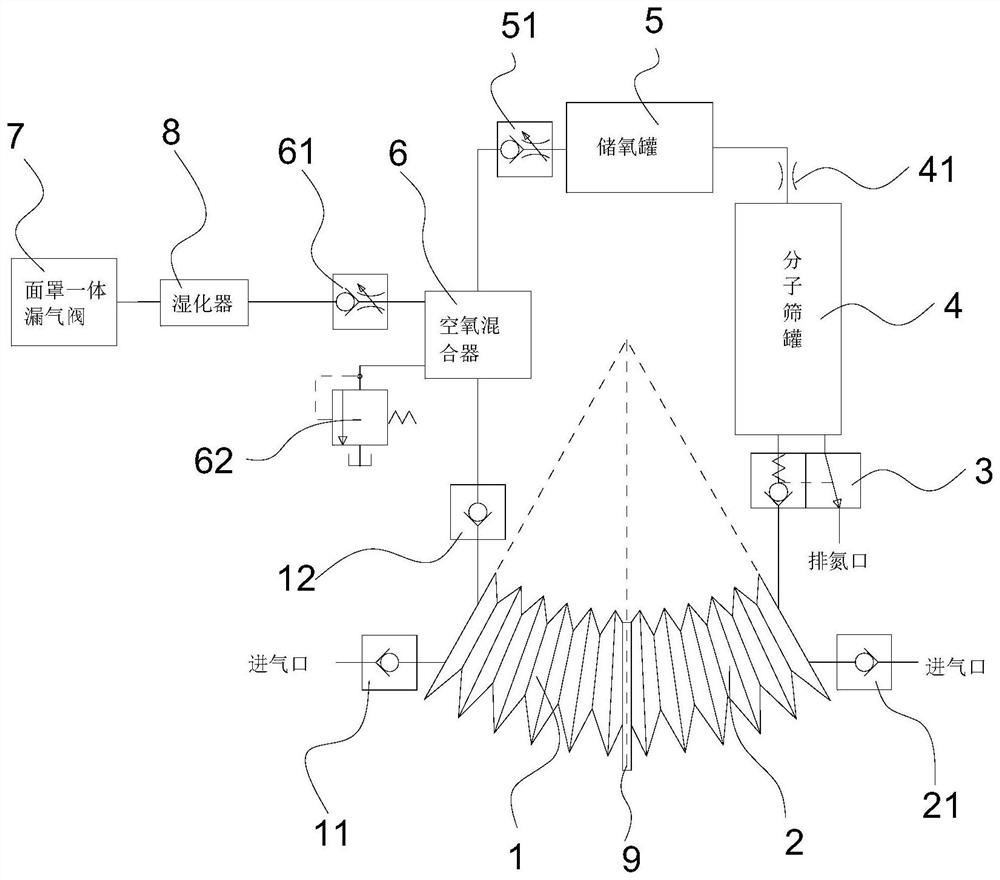

[0036] Such as figure 1 As shown, the ventilator includes a first airbag 1 and a second airbag 2 whose internal space can expand and shrink, a valve group, a molecular sieve tank 4, an oxygen storage tank 5, an air-oxygen mixer 6, and a mask integrated air leakage valve 7;

[0037]The first airbag 1 has an air inlet and an air outlet, the air inlet is provided with a first one-way valve 11, and the air outlet is provided with a third one-way valve 12, and the first airbag 1 is mixed with air and oxygen through the third one-way valve 12 The air-oxygen mixer 6 mixes the oxygen from the oxygen storage tank 5 and the air from the first air bag 1, and the air-oxygen mixer 6 is connected with the humidifier 8 through the second one-way throttle valve 61, and the humidifier 8 is connected with the mask integrated air leakage valve 7, and the air-oxygen mixer 6 is provided with an overflow valve 62 as a guarantee for exhalation safety.

[0038] The second airbag 2 has an air inlet a...

Embodiment 2

[0055] Such as Figure 5 As shown, the difference between this embodiment and embodiment one is that the number of molecular sieve tanks 4 is different:

[0056] In this embodiment, there are two molecular sieve tanks 4. Correspondingly, there are two two-position two-way linkage one-way pressure valves 3 and two throttle valves 41; a one-one two-way switching valve 42 is also included. After the second air bag 2 is connected to a one-position two-way switching valve 42, two two-position two-way linkage one-way pressure valves 3 are respectively connected, and the two-way linkage one-way pressure valve 3 is connected to a molecular sieve tank 4, and the top connection joint of the molecular sieve tank 4 Throttle valve 41, both throttle valves 41 are connected to oxygen storage tank 5.

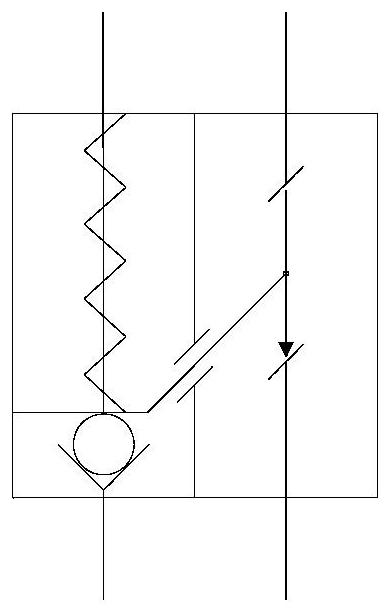

[0057] Such as Figure 6(a) , 6(b) As shown, the one-position two-way switching valve 42 includes a touch lever 421, a return spring 422, a one-way gear 423, a first rack 424, and a two-posi...

Embodiment 3

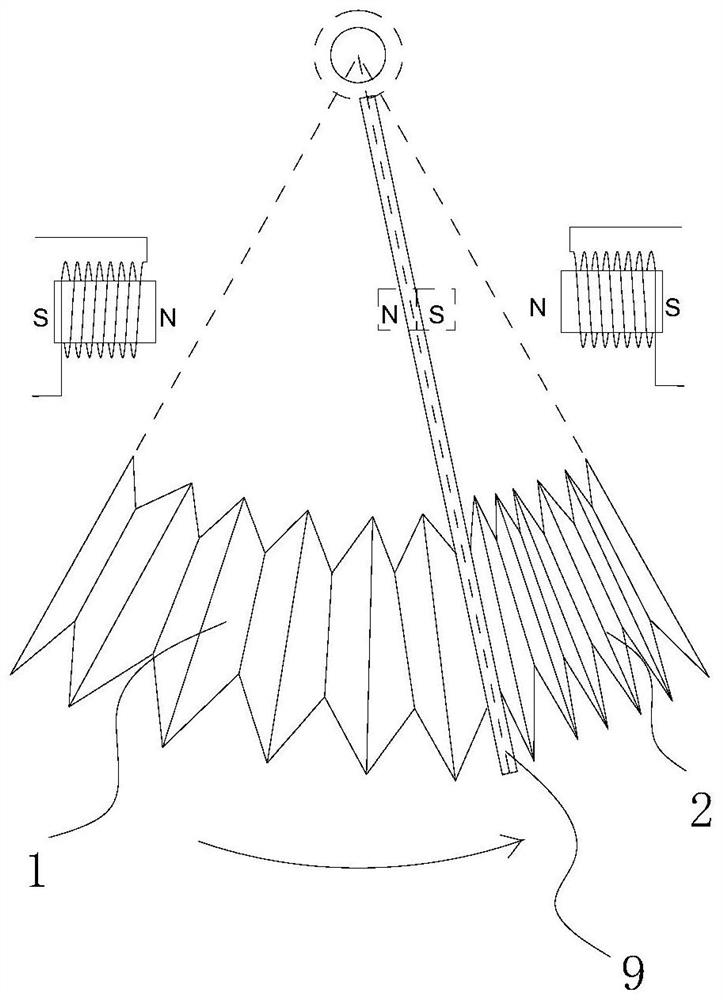

[0067] Such as Figure 8 , Figure 9 As shown, the difference between the present embodiment and the first embodiment lies in that the driving mode of the extruding plate 9 is different.

[0068] In this embodiment, the extruding plate 9 has a second rack 91 on the outside, and also includes a fixed driving gear 92 , and the second rack 91 meshes with the driving gear 92 .

[0069] Such as Figure 8 As shown, the driving gear 92 rotates clockwise, which drives the extrusion plate 9 to move to the right, compresses the second airbag 2, and expands the first airbag 1; Figure 9 As shown, the driving gear 92 rotates counterclockwise, driving the pressing plate 9 to move left, compressing the first airbag 1 and expanding the second airbag 2 .

[0070] In addition to realizing the left and right movement of the extrusion plate 9 through gear meshing, it can also be realized through mechanical structures such as chains, belts, and reciprocating screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com