Valve stent and interventional prosthetic heart valve

A valve and prosthesis technology, applied in the field of valve stents and interventional heart prosthetic valves, can solve the problems of poor stent fatigue performance, unstable anchoring, hindering left ventricular blood ejection, etc., to achieve strong anchoring force, not easy to slip or even shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

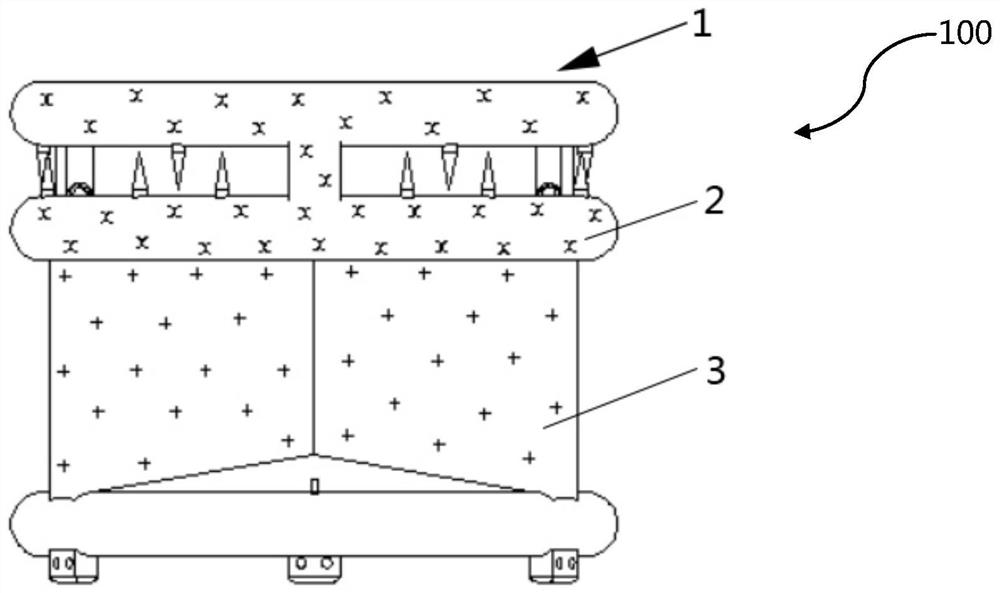

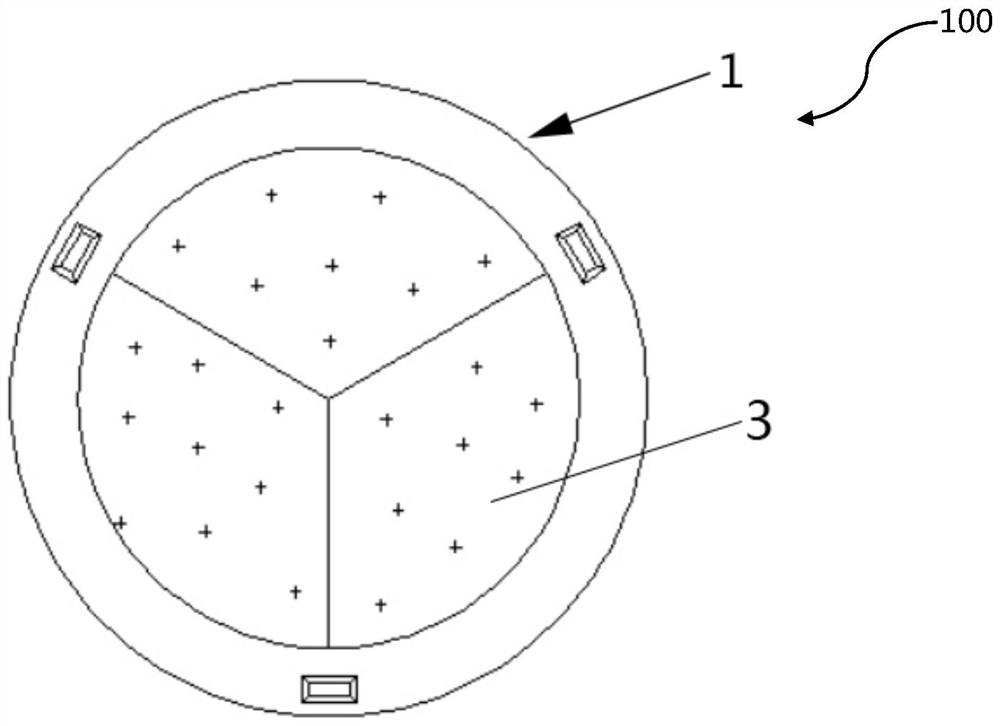

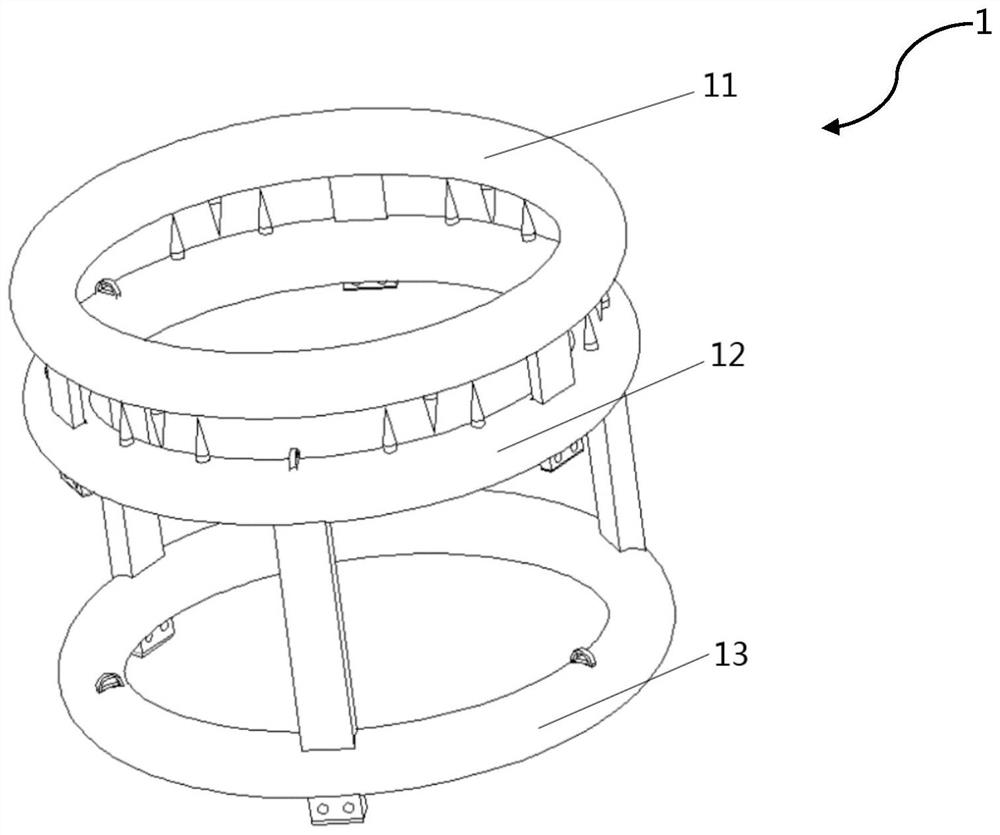

[0043] figure 1 It is a schematic front view of the three-dimensional structure of the prosthetic valve in Embodiment 1 of the present invention, figure 2 It is a schematic structural diagram of a three-dimensional top view of the prosthetic valve according to Embodiment 1 of the present invention;

[0044] like figure 1 as well as figure 2 As shown, the interventional heart valve stent and prosthetic valve 100 of this embodiment has a valve stent 1 , a skirt 2 and an artificial valve leaflet 3 .

[0045] Wherein, the valve support 1 is a supporting and positioning structure of the prosthetic valve 100, and is used for carrying the artificial valve leaflet 3, attaching the skirt 2, anchoring and positioning, and the like. The valve stent 1 is made of shape memory alloy, which includes NiTi (nickel-titanium alloy), CuAlNi (copper-aluminum-nickel alloy) and the like. In this embodiment, the valve support 1 is made of NiTi.

[0046] For the convenience of description, the ...

Embodiment 2

[0121] In the present embodiment, the same structures as in the first embodiment are given the same reference numerals and the same descriptions are omitted.

[0122] Figure 20 It is a schematic diagram of the three-dimensional structure of the groove ring structure of the second embodiment of the present invention, Figure 21 It is a three-dimensional structure schematic diagram of the grooved ring structure of the second embodiment of the present invention after matching.

[0123] like Figure 21 As shown, the main difference between the present embodiment and the first embodiment is that the connection between the middle ring bracket 12 and the lower ring bracket 13 is not completed by the telescopic buckle 127 and the groove 134, but is connected by a grooved ring structure.

[0124] Specifically, the middle ring connecting rod 122 of this embodiment is I-shaped, and a plurality of continuous engagement protrusions 129 are arranged radially on the surface of the middle ...

Embodiment 3

[0130] In the present embodiment, the same structures as in the first embodiment are given the same reference numerals and the same descriptions are omitted.

[0131] Figure 25 It is a schematic diagram of the three-dimensional structure of the middle ring bracket of the third embodiment of the present invention, Figure 26 It is a cross-sectional structure diagram of the pulling ring of the third embodiment of the present invention.

[0132] Such as Figure 25 as well as Figure 26 As shown, the main difference between this embodiment and Embodiment 1 is that the pulling ring 126 of the middle ring is not in the shape of a raised semicircular ring, but is recessed in the middle ring 121, a through hole in a U-shaped structure, on the surface of the middle ring bracket 12 It is in the shape of two holes, and the pulling rope can pass through the U-shaped through hole through the two holes to complete the pulling effect. In this embodiment, the number of the middle ring pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com