Small plate spraying device

A technology of spraying device and sheet metal, applied in the field of sheet metal processing, can solve problems such as harm to human health, omission of spraying, inconvenience in use, etc., and achieve the effects of improving molding quality, simple structure and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

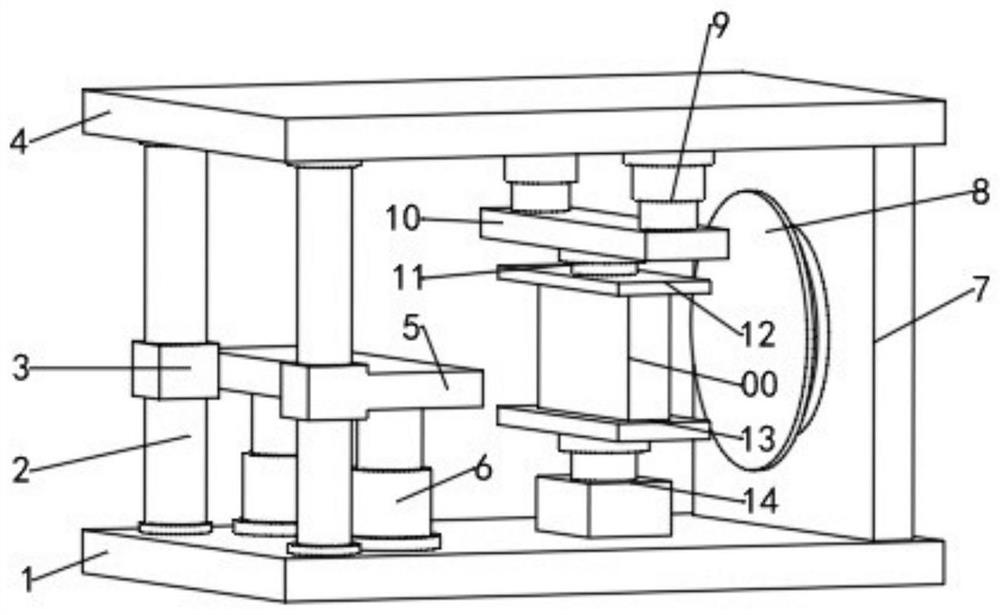

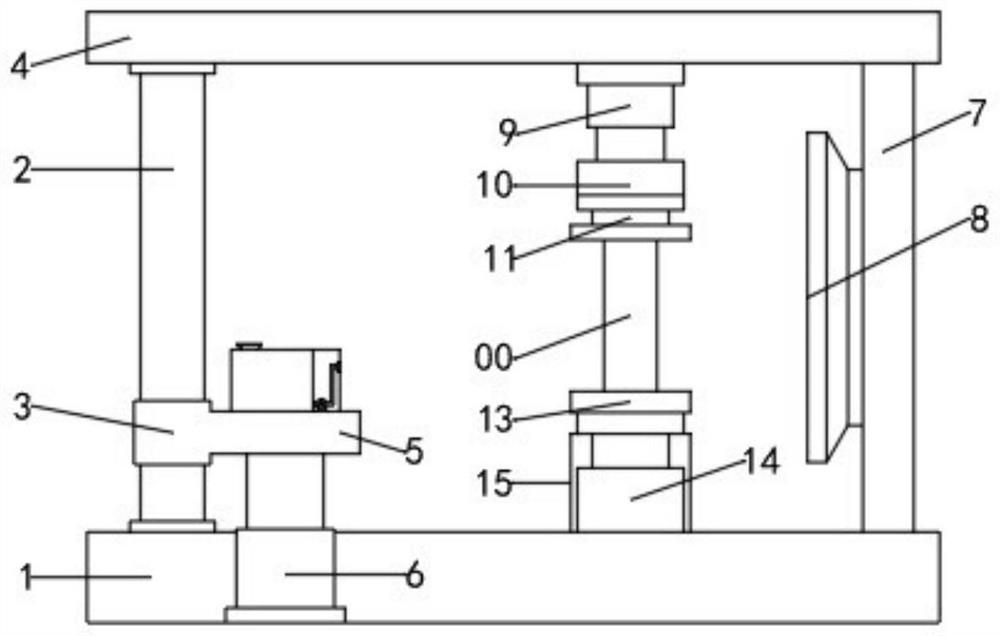

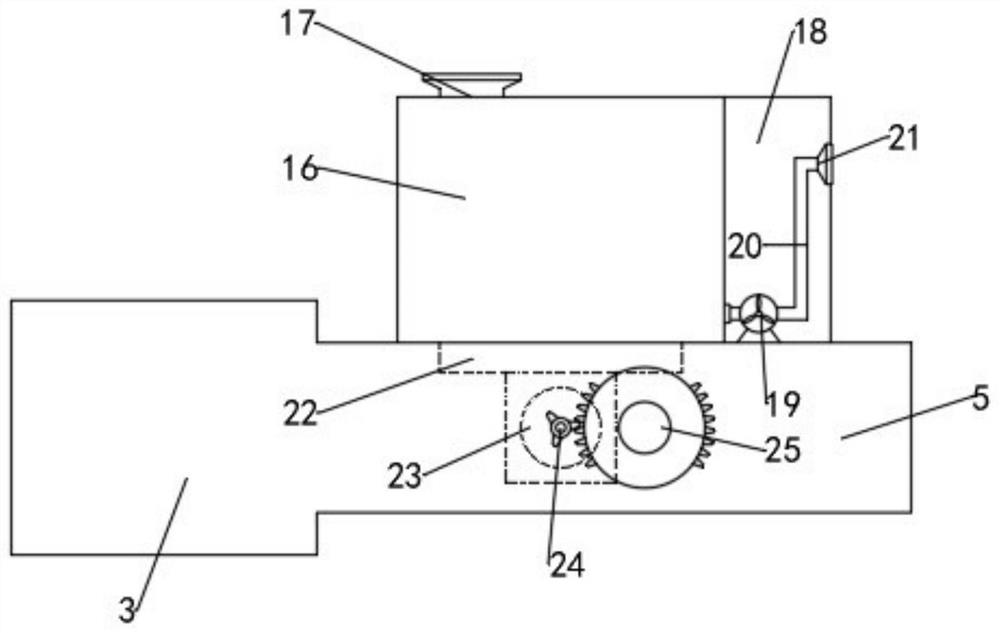

[0020] see Figure 1-4 , a small sheet material spraying device, comprising a base 1, one side of the upper end surface of the base 1 is fixedly connected with a vertical support rod 2, the number of the support rods 2 is two and arranged at intervals, and the two support rods One side of the 2 is provided with a vertical support plate 7, the base 1 is connected with a fixed seat 4 through the support bar 2 and the support plate 7, and the fixed seat 4 is located above the base 1; the support bar 2 is movably connected with a sliding seat 3 , the two sliding seats 3 are fixedly connected with a workbench 5, the workbench 5 is suspended above the base 1, and a spraying mechanism is placed on the workbench 5; a vertical servo is connected between the base 1 and the workbench 5 Electric cylinder 6, the number of servo electric cylinder 6 is two and arranged at intervals, the actuator rod of servo electric cylinder 5 is connected with the lower end of workbench 5; The top of the ...

Embodiment 2

[0029]In Example 1, after the plate 00 is sprayed, the placement direction of the plate 00 can be reversed through the rotary cylinder 14, so that the plate 00 can be sprayed in all directions. In order to improve the paint surface forming efficiency of the plate 00, this The embodiment is improved on the basis of embodiment 1. The improvement is: the support plate 7 is equipped with a dryer 8 at the center of one side close to the rotary cylinder 14, and the dryer 8 is in the shape of a lampshade to facilitate the alignment of the plates. The paint surface of material 00 is dried quickly, which improves the molding quality of the paint surface and speeds up the spraying efficiency of the surface of material 00.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com