Paint spaying device with drying function for industrial robot production

An industrial robot and functional technology, which is applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of inconvenient fixing of robot parts of different specifications and low use range, so as to improve the fixing effect, Improve the stirring effect and prevent the effect of paint agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

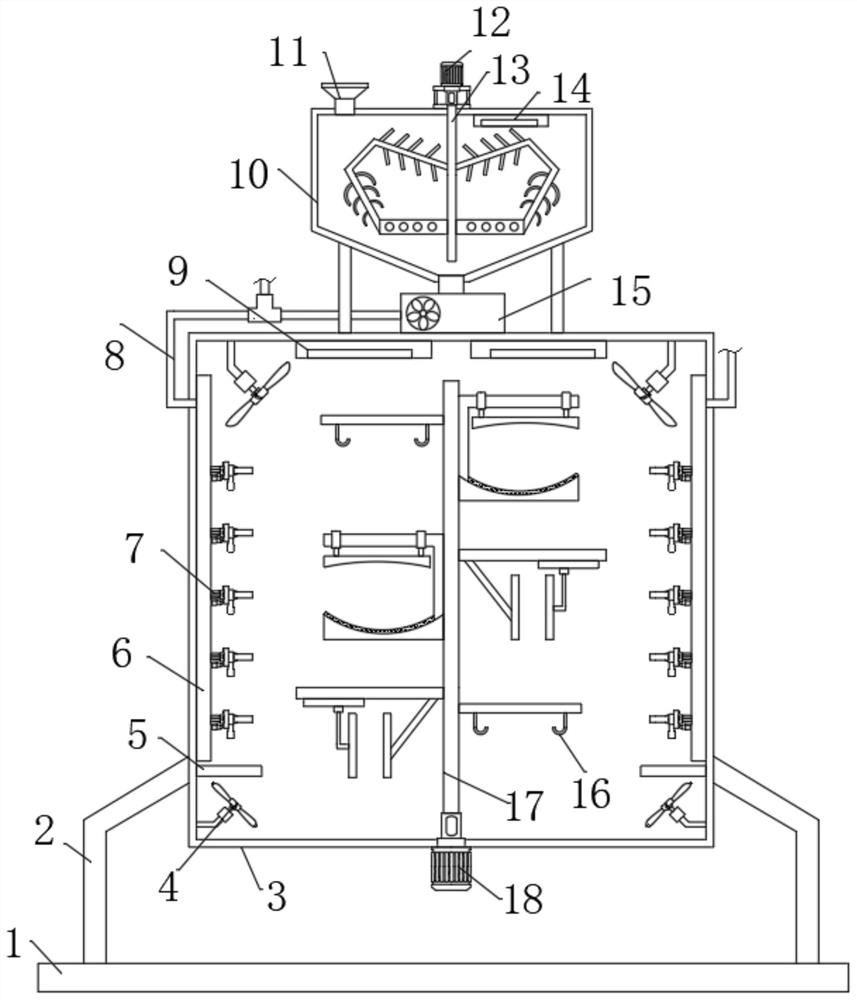

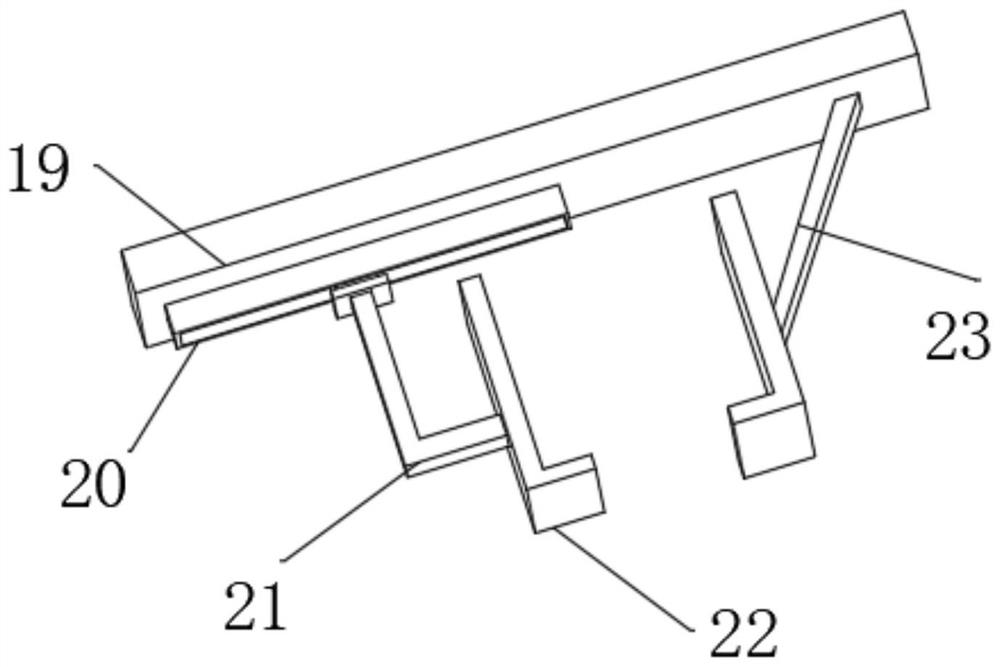

[0030] Reference Figure 1-4 , A paint spraying device for industrial robot production with drying function, comprising a bottom plate 1. The top and outer walls of the bottom plate 1 are welded with support legs 2 on both sides, and the other end of the support leg 2 is fixed with a spray paint box 3 by screws. The bottom outer wall of 3 is fixed with a second motor 18 by screws, and the output shaft of the second motor 18 is connected with a second rotating rod 17 through a coupling. The outer wall of the second rotating rod 17 is welded with a second fixing plate, and Hooks 16 are welded on both sides of the bottom outer wall of the fixing plate. Both sides of the outer wall of the second rotating rod 17 are fixed with a fixing plate 19 by screws. The bottom outer wall of the fixing plate 19 is fixed with a slide rail 20 by screws. A fixed rod 21 is slidably connected to the inner wall. The bottom outer wall of the fixed plate 19 is welded with a connecting rod 23. The other...

Embodiment 2

[0038] Reference Figure 5 , A paint spraying device for the production of industrial robots with drying function. Compared with the first embodiment, this embodiment also includes a temperature sensor 32 fixed to the inner wall of the top of the mixing box 10 by screws, and one side of the outer wall of the mixing box 10 is fixed by screws There is a display screen 33, and the signal input terminal of the display screen 33 is connected to the processor through a signal line, and the signal output terminal of the temperature sensor 32 and the signal input terminal of the processor are connected through a signal line.

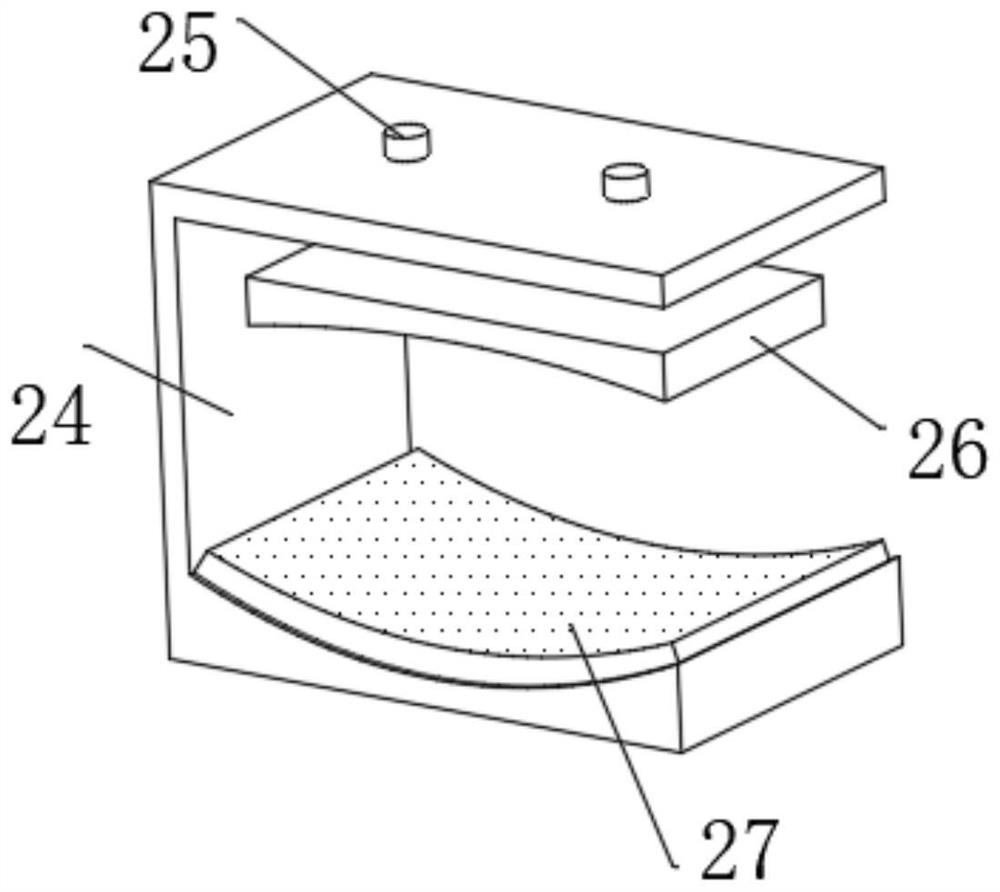

[0039] Connect the equipment to the power supply and choose the appropriate fixing according to the specifications of the industrial robot parts. The hook 16 can fix the parts with holes. The round parts can be placed on the fixing frame 24, and the hydraulic rod 25 can be connected to the hydraulic The system adjusts the length of the hydraulic rod 25 to make the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com