A kind of rope washing machine and its working method

A washing machine and rope-like technology, which is applied in liquid/gas/vapor rope-like fabric treatment, textile processing machine accessories, spray/jet textile material treatment, etc. To avoid problems such as ground space, to prevent entanglement, improve washing effect, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

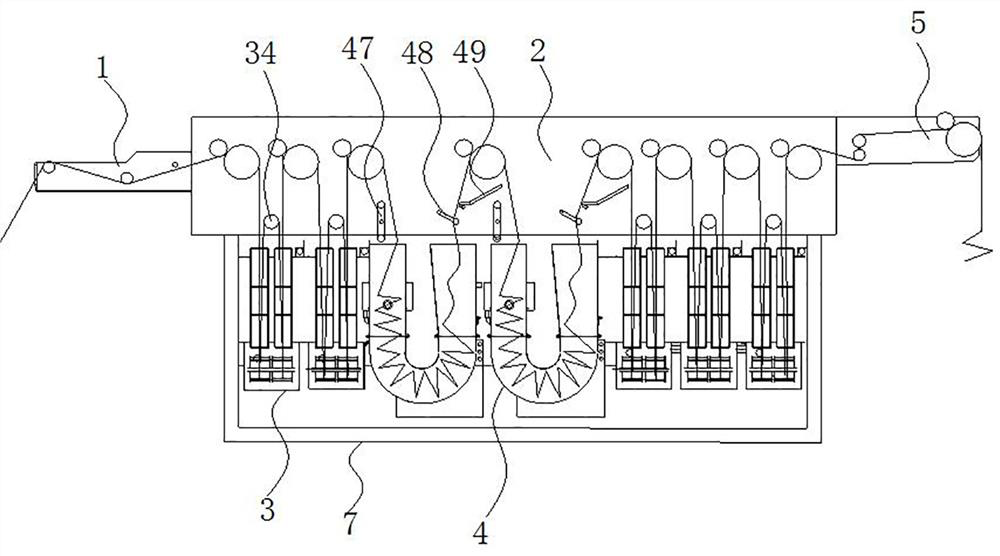

[0028] The present invention provides a technical solution:

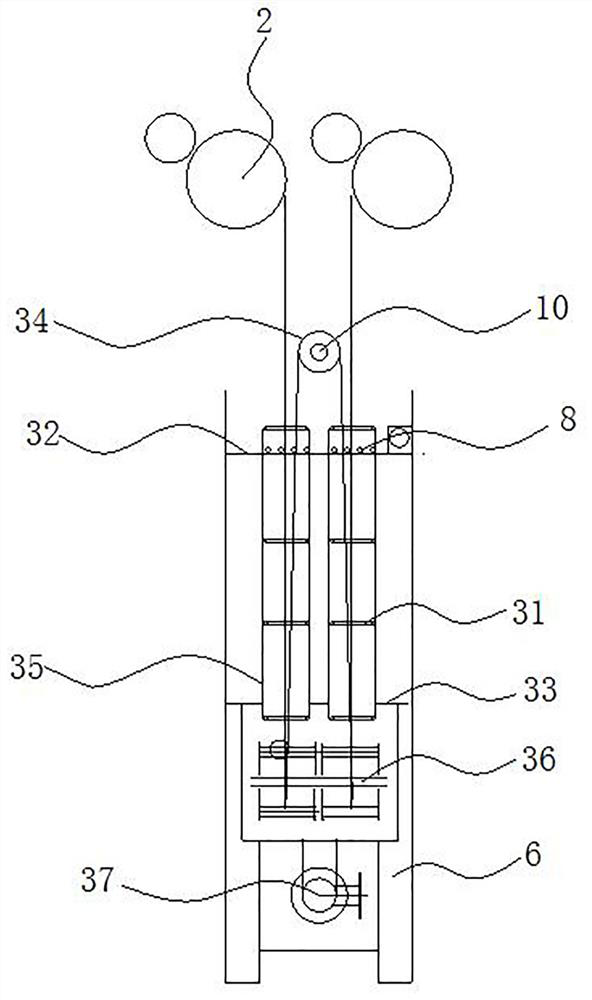

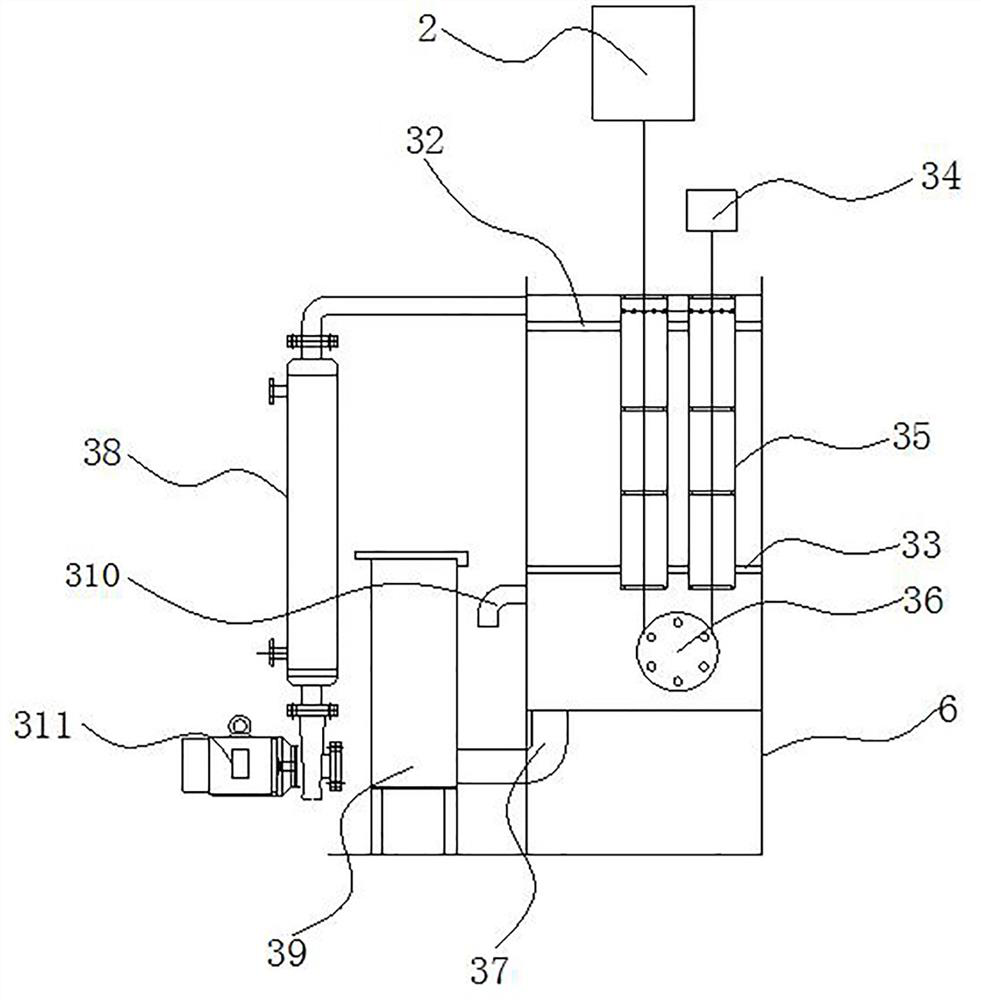

[0029] See figure 1 , A rope is washer, including inlet rack 1, rolling unit 2, upright multi-tube spray water washing mechanism 3, U-shaped soap cooking mechanism 4 and outlet frame 5, rolling unit 2 is common in the art The transmission device, typically includes a device chassis, a drive source (motor), and various types of transmission rollers, the present application uses a corresponding transmission roller with a rolling unit 2, the spray tube 35, and the U-shaped box 41 commonly used in the art. To achieve continuous work between the agency, it belongs to the prior art direct reference, and does not describe it, the mount 1 and the outlet 5 are mounted on the left and right sides of the rolling unit 2, soothless The spray water washing mechanism 3 and the U-shaped soap cooking mechanism 4 are mounted in the case 7 located under the rolling unit 2, and the fabric is moved by the left to right, and the latter water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com