Oil extraction method and CO<2> injection amount determination method and device used for assisting huff-puff oil increase

A technology to determine the method and injection rate, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of excessive or too little injection rate, low oil recovery efficiency, etc., and achieve cycle production time extension, High oil production efficiency and enhanced oil recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

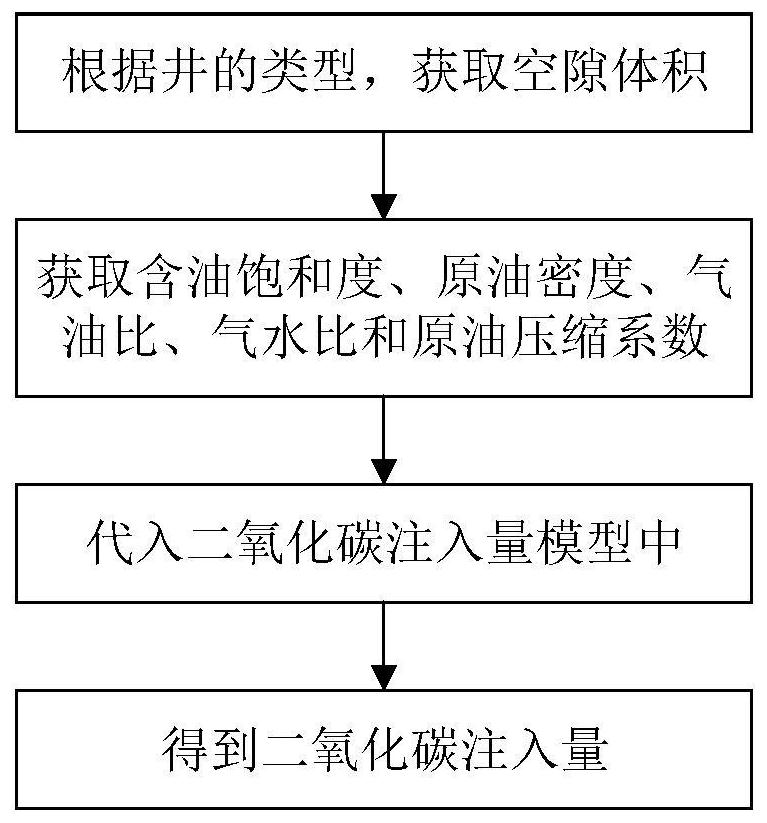

[0035] A method for determining the injection amount of carbon dioxide for assisting throughput and increasing oil according to the present invention, the method considers the physical parameters of the oil layer and the solubility of carbon dioxide in oil and water to determine the injection amount of carbon dioxide. Combine below figure 1 , to describe the method in detail.

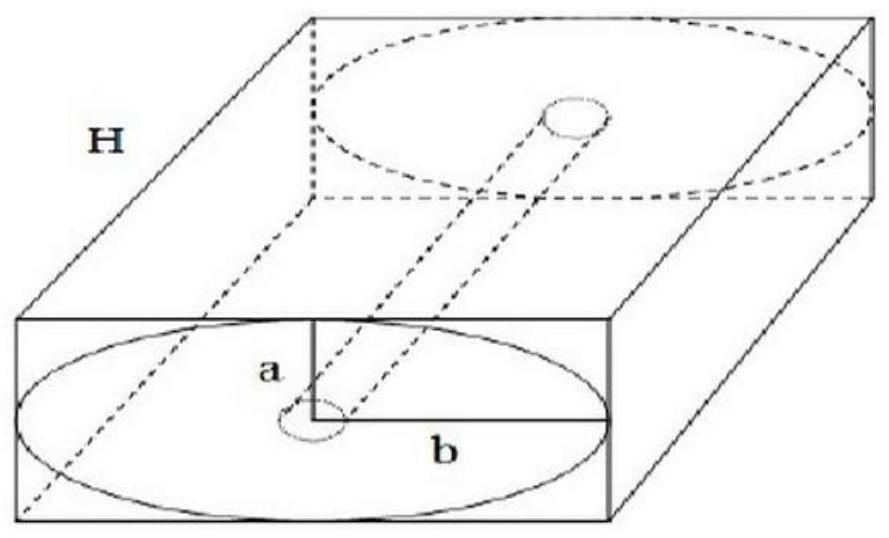

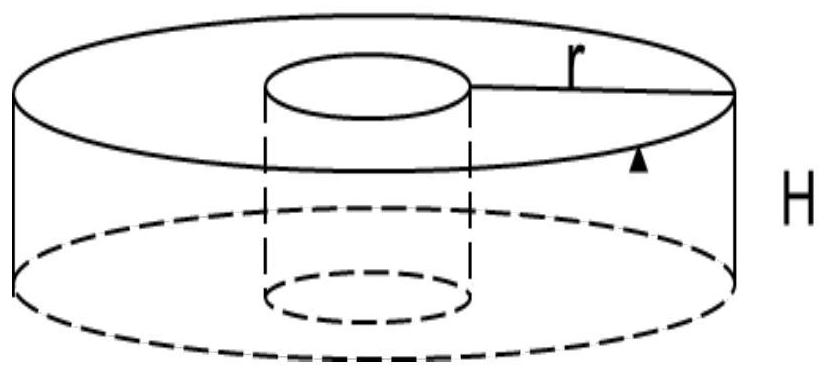

[0036] First, according to the following relationship: pore volume V p and carbon dioxide injection Positively correlated, crude oil density ρ 0 and carbon dioxide injection Positively correlated, the gas-oil ratio R 0 and carbon dioxide injection Positively correlated, air-water ratio R w and carbon dioxide injection Positively correlated, crude oil compressibility B 0 and carbon dioxide injection Negatively correlated, build a carbon dioxide injection model, the model is:

[0037]

[0038] In the formula, is the amount of carbon dioxide injected, t; V p is the pore volume, m 3 ;S...

Embodiment 2

[0050] In implementation 1 of the method for determining the amount of carbon dioxide injection used to assist throughput increase, in the carbon dioxide injection amount model, the set coefficient k is set to 509. In this implementation, the set coefficient k is no longer 509, and adjustments are made on the basis of 509 to increase or decrease appropriately.

[0051] Embodiment of the device for determining the amount of carbon dioxide injection used to assist throughput and increase oil:

[0052] A device for determining the amount of carbon dioxide injection for assisting throughput increase of the present invention, such as Figure 4 As shown, the device includes a memory, a processor and an internal bus, and the processor and the memory communicate with each other through the internal bus.

[0053] The processor may be a processing device such as a microprocessor MCU or a programmable logic device FPGA.

[0054] The memory can be a high-speed random access memory, or a...

Embodiment 3

[0109] In oil recovery method implementation 1, in order to avoid damage to the insulated oil pipe caused by steam injection after injection of low-temperature liquid carbon dioxide, nitrogen gas is also injected at the same time as carbon dioxide injection. In this embodiment, nitrogen gas is not injected together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com