Fuel atomizing nozzle of sliding arc plasma-high disturbance cross structure

A plasma and fuel atomization technology, applied in fuel injection devices, engine ignition, engine components, etc., can solve problems such as difficult to achieve large flow of liquid fuel ionization, easy deactivation of active particles, narrow processing range, etc., to achieve Large-flow fuel oil treatment, combustion promotion, good ignition reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

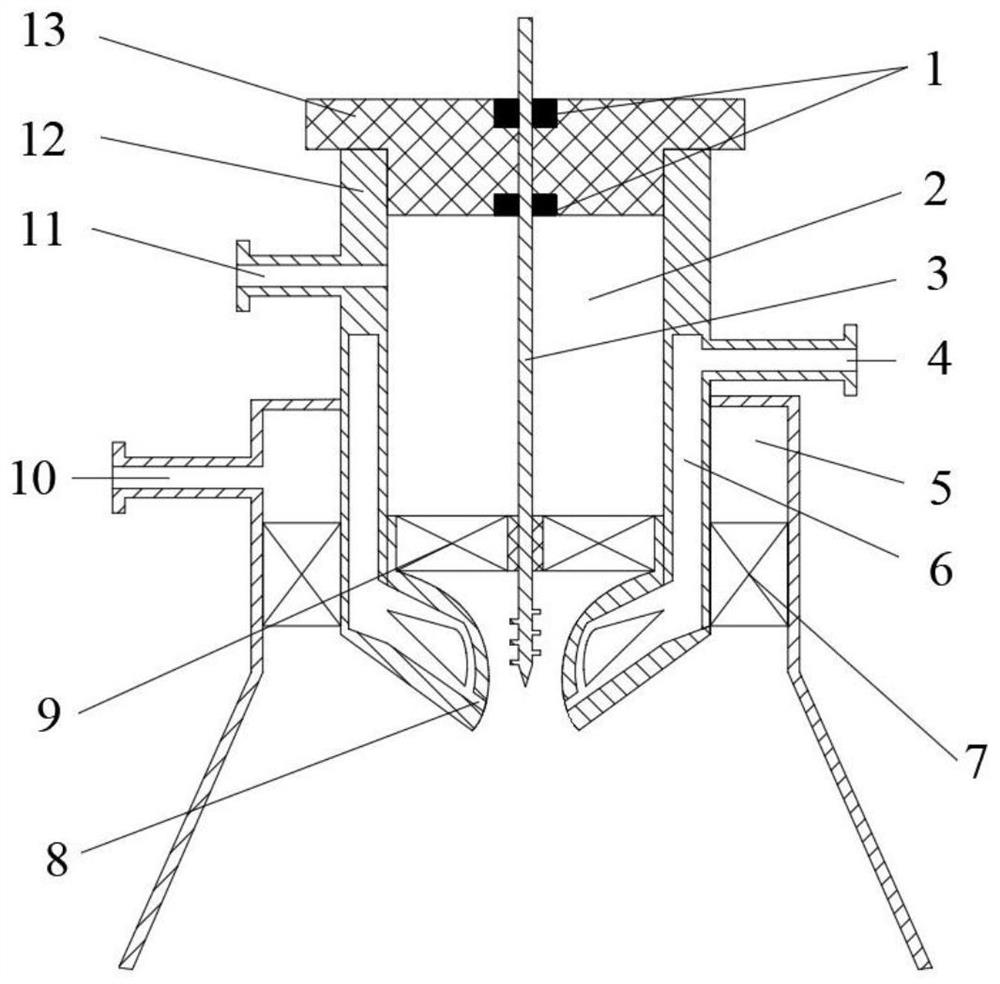

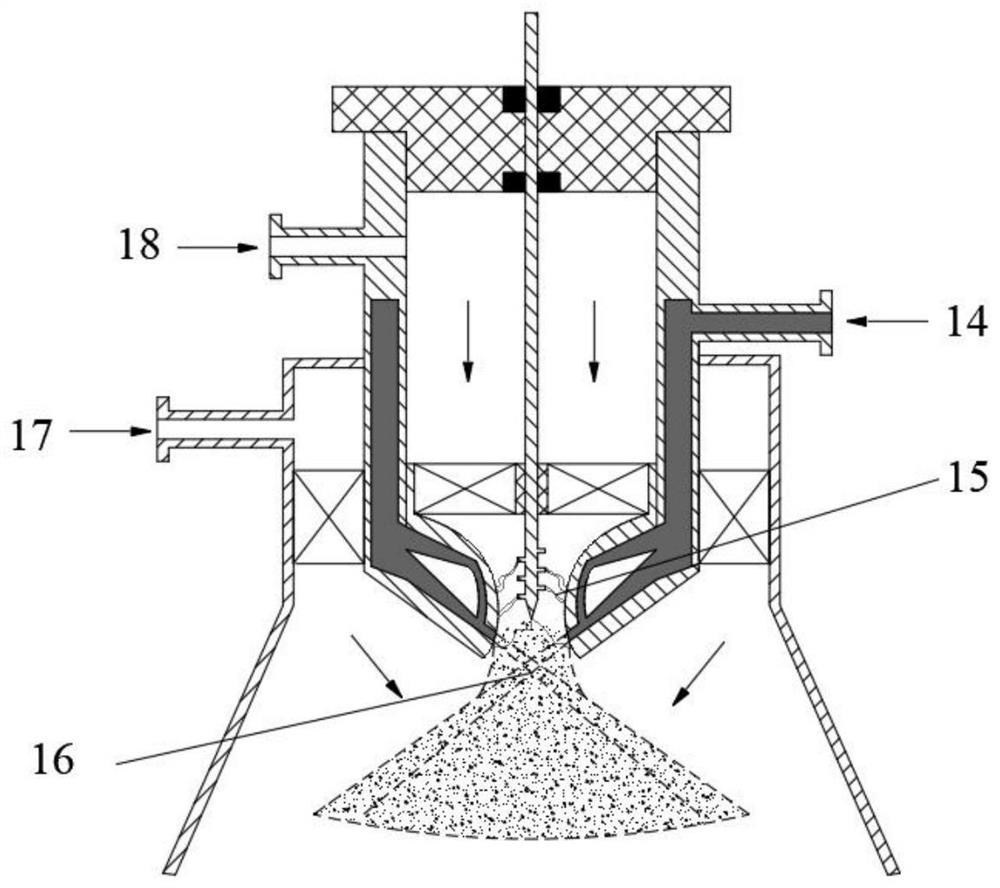

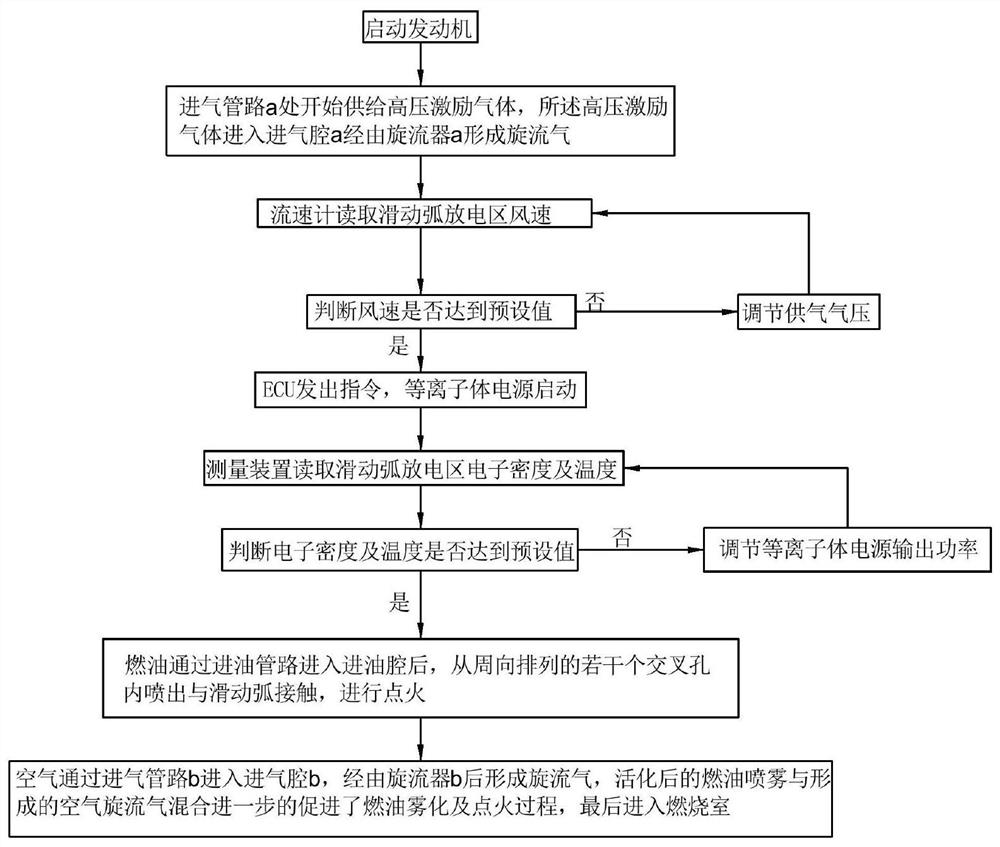

[0024] like Figure 1-3 As shown, this embodiment provides a fuel atomizing nozzle with a sliding arc plasma-high disturbance cross structure. During operation, the tungsten electrode is used as a high-voltage electrode and is connected to the positive electrode of the plasma power supply. The tungsten electrode is connected by a threaded The method is connected with the end cover and the cyclone a, and at the same time, the bottom of the tungsten electrode is distributed with small protrusions in a spiral arrangement, which can improve the discharge efficiency of the sliding arc; the end cover and the inner shell are installed in a threaded manner Together, at the same time, the end cover is made of insulating material, and two grooves are opened on the end cover, and a metal locator is arranged in each groove, and the function of the metal locator is to realize the tungsten The positioning adjustment of the upper and lower positions of the electrodes; the fuel enters the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com