A kind of battery positive electrode sheet, flexible packaging lithium carbon fluoride primary battery and preparation method thereof

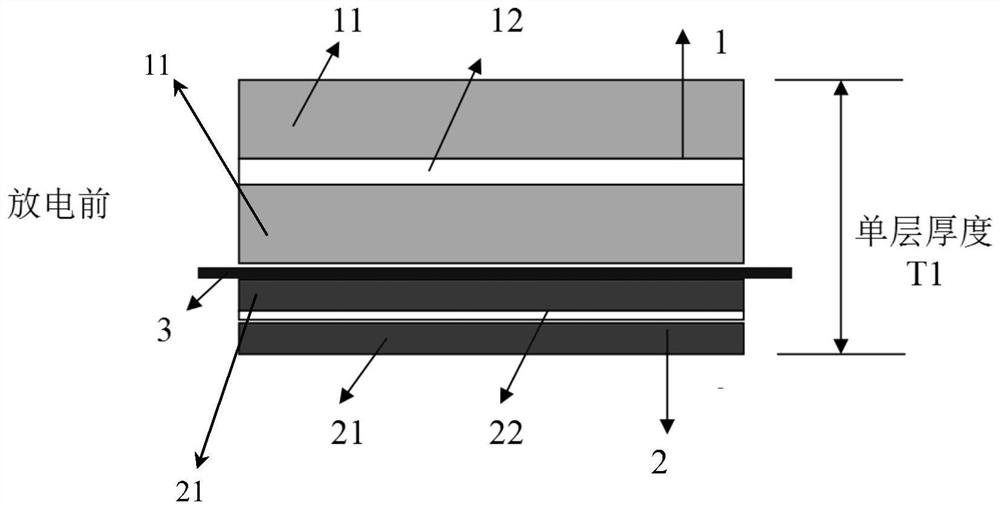

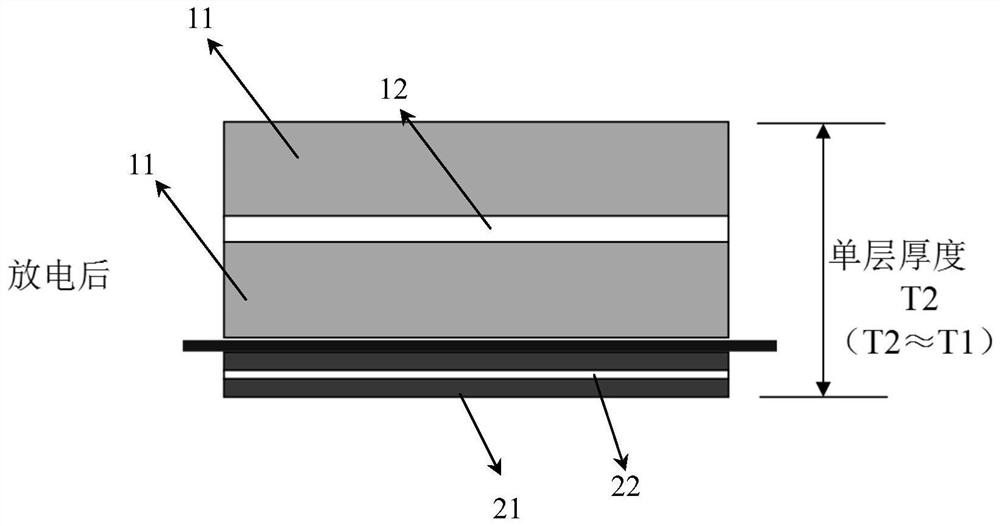

A battery positive electrode and carbon fluoride technology, which is applied in the direction of the primary battery electrode, battery electrode, positive electrode, etc., can solve the problems of uneven thickness variation of the positive electrode sheet, battery thickness expansion, and increased spacing, so as to improve the capacity utilization rate , good interface contact, reduce the effect of discharge expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

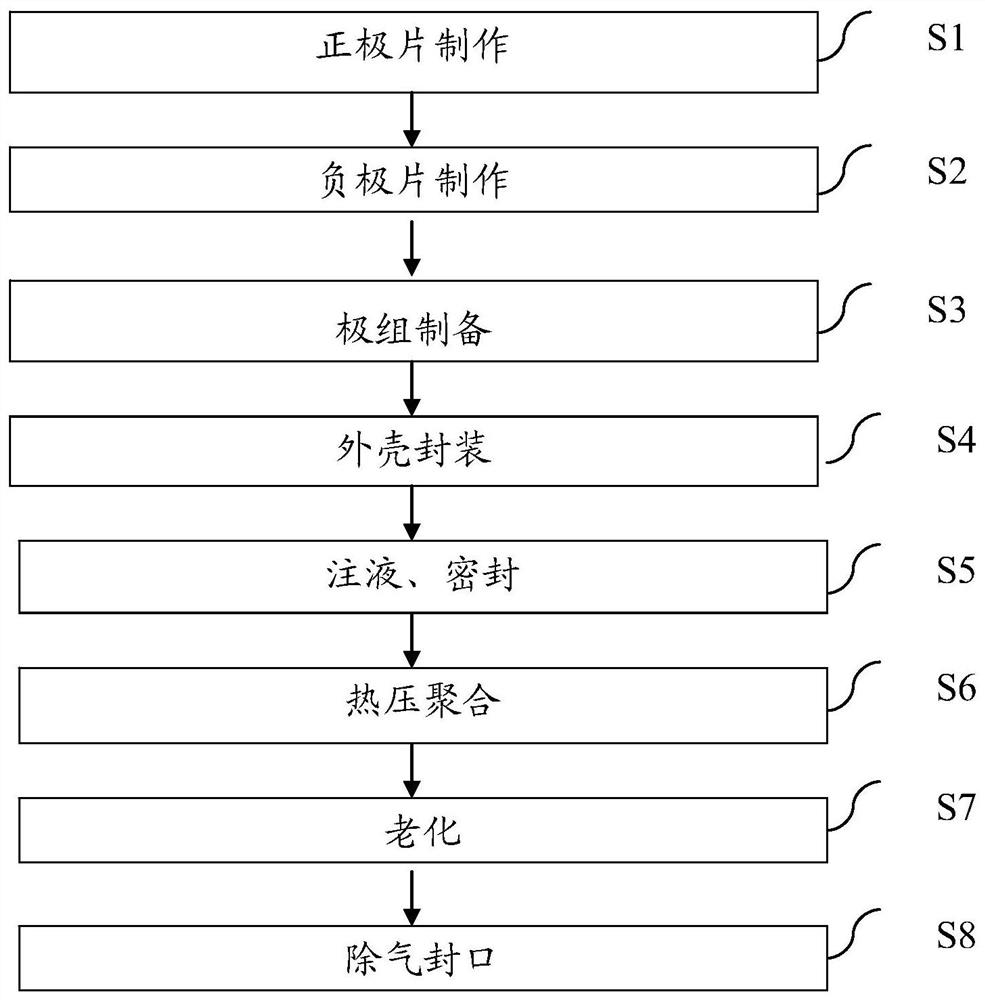

[0127] In order to prepare and obtain the above-mentioned flexible packaging lithium carbon fluoride primary battery provided by the present invention, refer to figure 2 As shown, the present invention also provides a preparation method of a flexible packaging lithium carbon fluoride primary battery, comprising the following steps:

[0128] Step S1, production of the positive electrode sheet: the positive electrode active material, the conductive agent and the binder are mixed uniformly according to the preset mass ratio, and then dispersed in the solvent NMP to prepare the positive electrode slurry, and then the positive electrode slurry is uniformly coated on the The surface of the aluminum foil used as the positive electrode current collector is then dried, rolled and sheared in sequence to obtain a positive electrode piece;

[0129] In the present invention, in terms of specific implementation, in step S1, the mass ratio between the positive electrode active material, the...

Embodiment 1

[0143] A flexible packaging lithium carbon fluoride primary battery with a capacity of about 4650mAh was prepared. The positive electrode active material was made of 100% carbon fluoride. The carbon fluoride has the characteristics of high power discharge and high discharge platform. Three-dimensional through-hole multi-level channel structure, including abundant macropores, mesopores and a small amount of micropores, with a specific surface area of about 610m 2 / g, the actual gram capacity of the fluorocarbon material discharged at 0.1C at room temperature is about 680mAh / g. The negative electrode active material is pure metal lithium with a theoretical gram capacity of 3860mAh / g and a density of 0.534g / cm 3 . The total thickness of the separator is 20 μm, the base material of the separator is polyethylene PE, the thickness of the base of the separator is 16 μm, and the base of the separator is coated on both sides with a hybrid function of ceramic and organic binder (viny...

Embodiment 2

[0159] A flexible packaging lithium carbon fluoride primary battery with a capacity of about 4650mAh was prepared. The positive active material was a mixture of carbon fluoride and electrolytic manganese dioxide, wherein carbon fluoride: manganese dioxide = 8:2 (mass ratio), and the fluoride used was The carbon material was the same as in Example 1, and the actual gram capacity of electrolytic manganese dioxide discharged at 0.1 C at room temperature was about 250 mAh / g. The negative electrode is made of pure metal lithium with a theoretical gram capacity of 3860mAh / g and a density of 0.534g / cm 3 . The total thickness of the diaphragm is 20μm, the base material is polyethylene PE, the base body thickness is 16μm, the double-sided coating is a hybrid functional coating of ceramic and organic binder (vinylidene fluoride-hexafluoropropylene copolymer), and the thickness of the single-sided coating is 2 μm.

[0160] The specific design and preparation method of the battery are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com