Full-automatic sealing and welding machine for quartz crystal resonator and sealing and welding method

A quartz crystal and resonator technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of many affected factors, hidden dangers of production safety, and low work efficiency, so as to achieve safe and convenient operation, ensure rapid discharge, and high consistency of finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

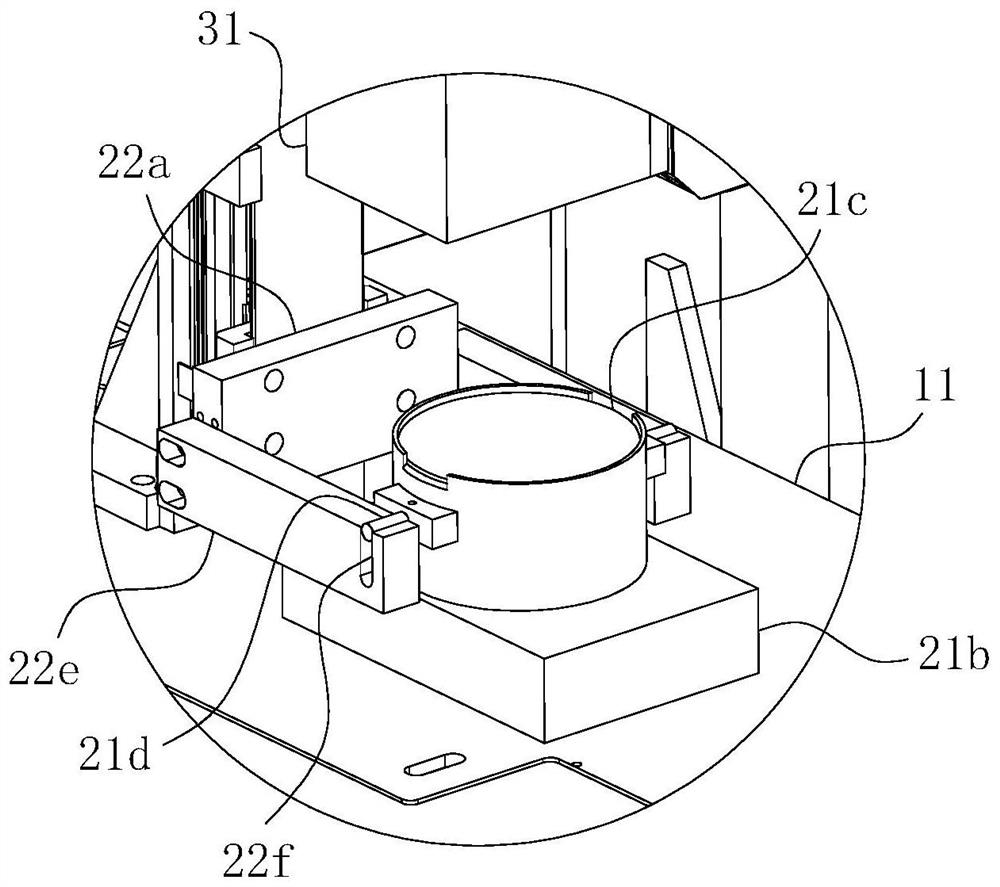

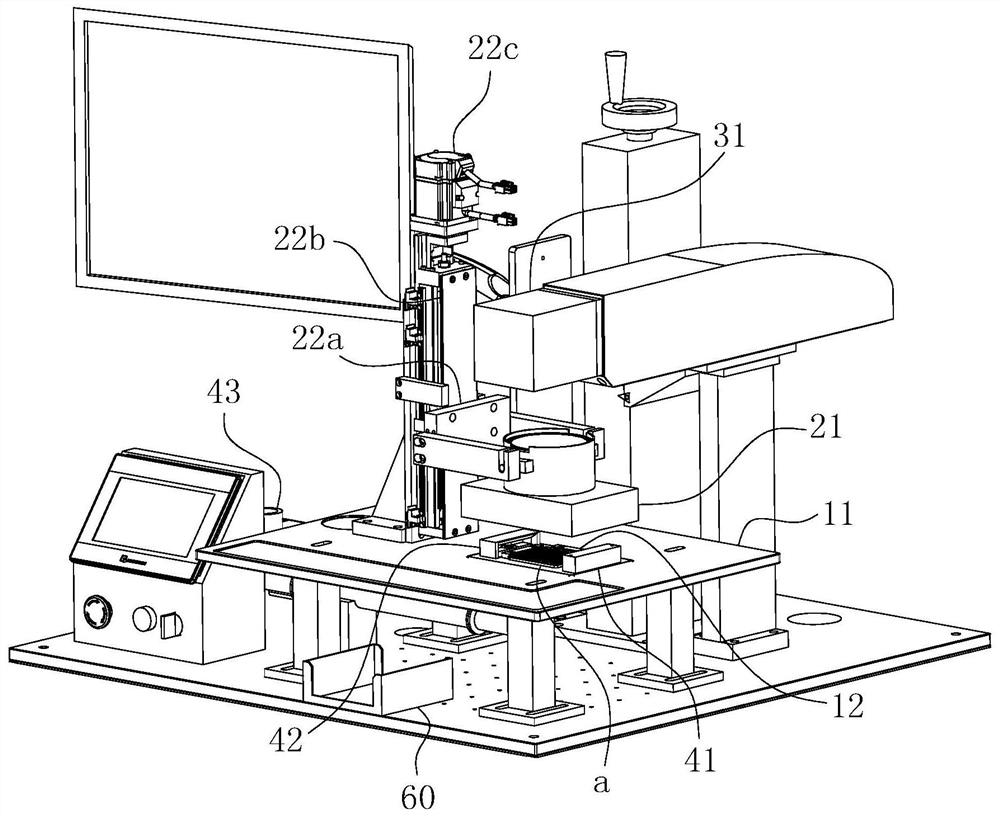

[0051] For ease of understanding, combined here Figure 1-5 , the concrete structure and working mode of the present invention are further described as follows:

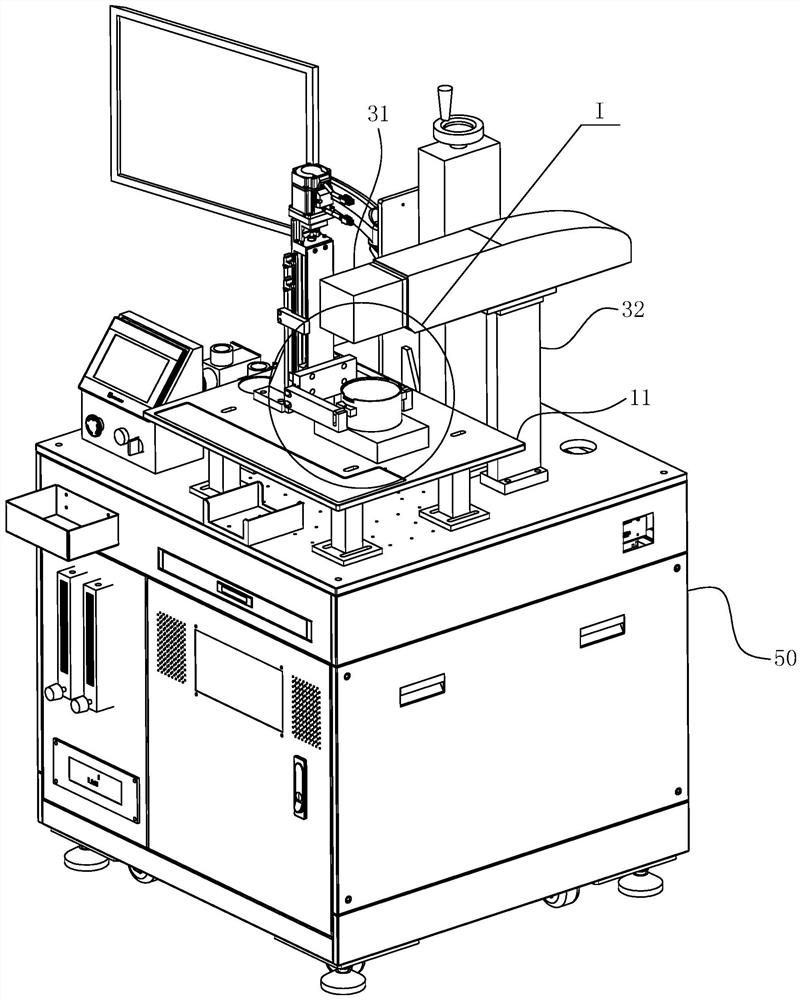

[0052] The specific structure of the present invention is as Figure 1-5 As shown, its main structure includes a frame 50, on which are respectively installed table top components, vacuum cover components, laser sealing and welding components and air pressure components, wherein:

[0053] Structural reference for deck components Figure 1-3 As shown, it includes a horizontal worktable 11 supported by several vertical support rods. A lower mold 12 is arranged on the worktable 11. The mold surface of the lower mold 12 constitutes a positioning surface for placing and positioning the resonator a to be packaged. In order to ensure the welding efficiency, in the actual layout, the lower mold 12 actually only needs to use two horizontal and two vertical or two horizontal and one vertical rectangular pieces to form a "mou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com