Low-energy-consumption energy-saving chemical light component removal tower

An energy-saving and low-energy-consumption technology, which is applied in the field of low-energy-saving energy-saving chemical light removal towers, can solve the problems of heat energy loss and low heating efficiency, and achieve the effects of reducing energy consumption, convenient collection, and improving heating effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

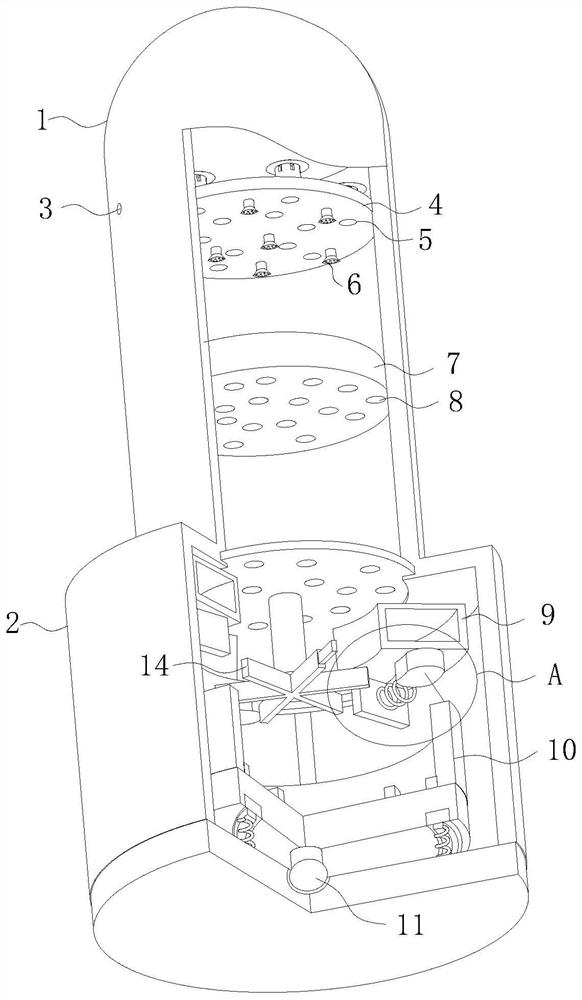

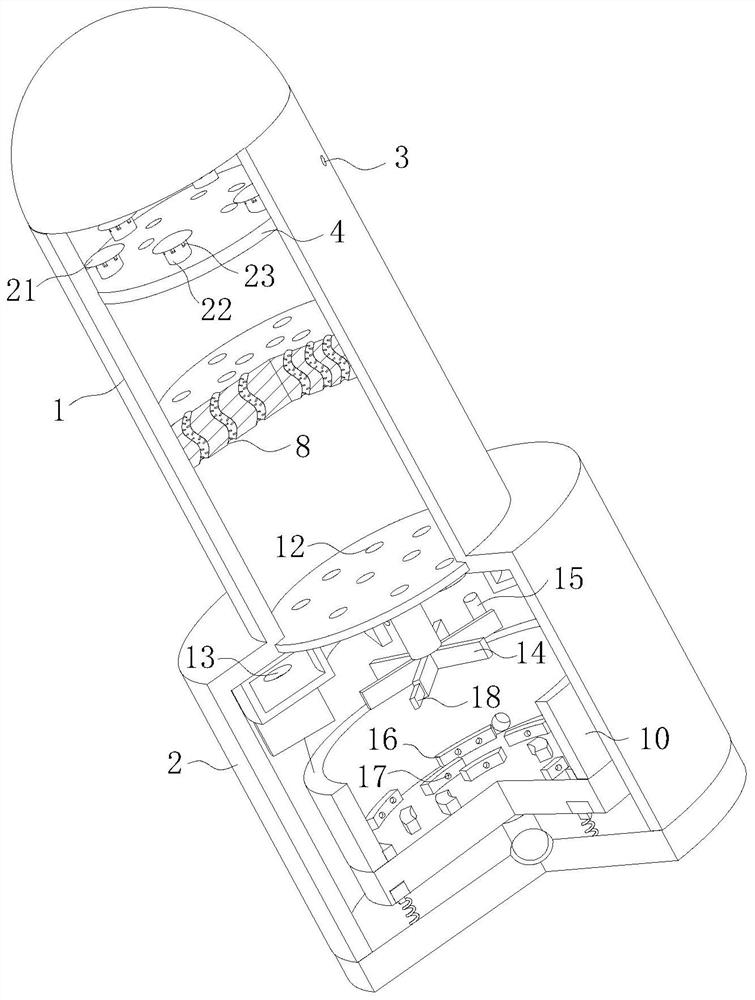

Method used

Image

Examples

Embodiment approach

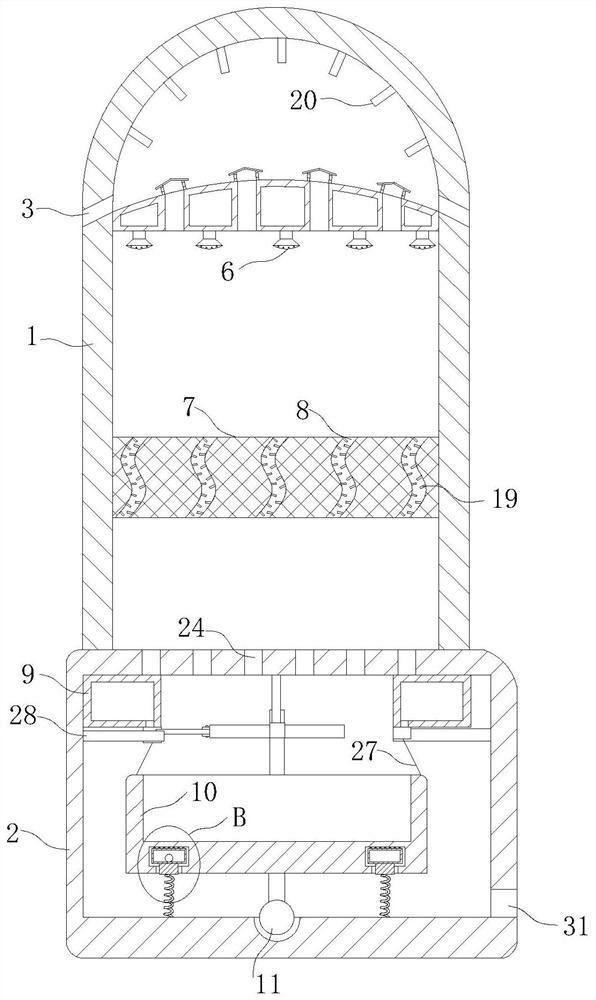

[0029] As an embodiment of the present invention, the filling hole 8 is an S-shaped structure; the relative positions of the inner walls of the filling hole 8 are uniformly staggered with baffles 19; the baffles 19 are arranged obliquely downward; , the filling hole 8 is an S-shaped structure, and the relative positions of the inner walls of the filling hole 8 are uniformly staggered with baffles 19, thereby greatly increasing the path where the gas phase and the liquid phase meet, and increasing the meeting time between the gas phase and the liquid phase, so that The low-boiling components in the liquid phase can be fully transferred to the gas phase, so that the light removal is more thorough.

[0030] As an embodiment of the present invention, the bottom of the evaporating tray 10 is provided with an annular slide rail 34; the annular slide rail 34 and the inner annular slide plate 32 are slidingly connected to each other; The top of the spring is fixedly connected to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com