High-pressure water pressure-resistant filtering method

A filtration method, high-pressure water technology, applied in filtration separation, membrane filter, separation method, etc., can solve the problems of poor fluid filtration efficiency, unstable high-pressure fluid filtration, etc., to reduce impact force, increase stability and high efficiency , the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

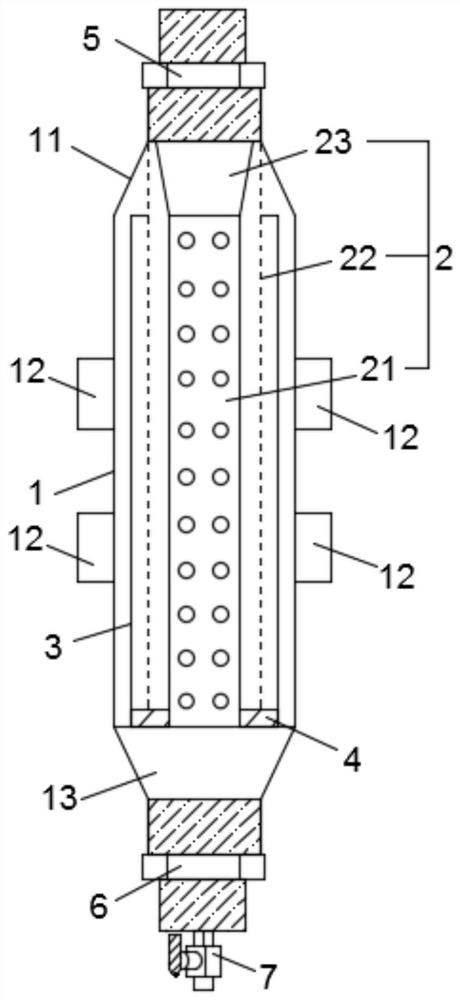

[0044] This embodiment discloses a high-pressure water anti-pressure filtration method, using such as figure 1 The pressure-resistant filter device shown includes a filter device main body 1 , a fine filter assembly 2 , a high-voltage protection sleeve 3 , a first joint 5 , a second joint 6 and a cleaning switch 7 .

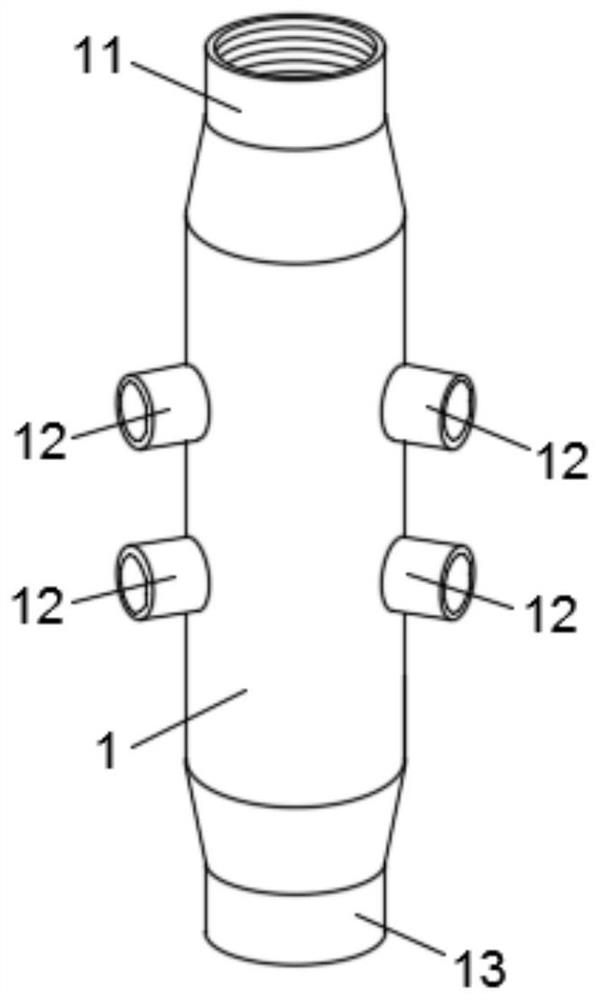

[0045] like figure 2As shown, the filter device main body 1 of this embodiment is an existing cylindrical filter cartridge structure, and the top of the filter device main body 1 is provided with a water inlet 11 integrally formed with it, and the water inlet 11 can also be directly welded by using existing welding techniques On the top of the filter device main body 1, and the inner wall of the water inlet 11 is provided with an internal thread;

[0046] The outer ring wall of the filter device main body 1 is provided with a plurality of water outlets 12 integrally formed with it, and the plurality of water outlets 12 can also be directly welded on the outer r...

Embodiment 2

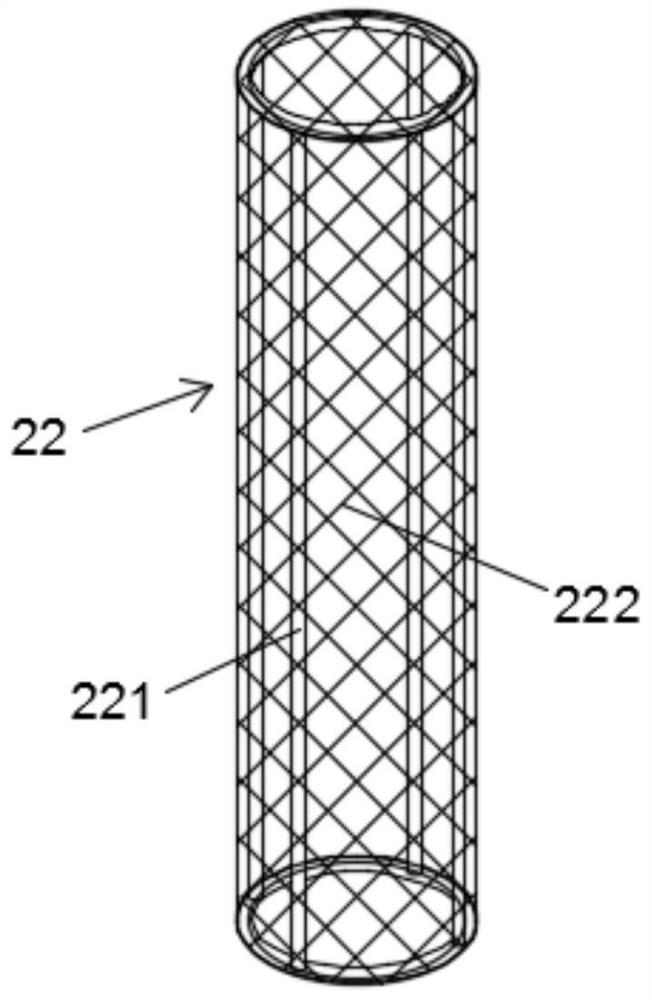

[0062] The difference between this embodiment and the above-mentioned embodiment is that: figure 1 , Image 6 ,and Figure 7 As shown, this embodiment also includes a sealing ring 4 arranged between the first-stage filter screen pipe 21 and the high-pressure protection casing 3. The sealing ring 4 of this embodiment adopts an existing rubber sealing ring with a certain thickness. The sealing ring 4 is set on the lower end of the Class I filter screen pipe 21, and the inner hole wall of the sealing ring 4 is in interference fit with the outer ring wall of the lower end of the Class I filter screen pipe 21; And the inner wall of the lower port of the high-pressure protection sleeve 3 is in interference fit with the outer ring wall of the sealing ring 4;

[0063] The inner hole diameter of the sealing ring 4 is smaller than the inner hole diameter of the lower ring 2212, and the outer diameter of the sealing ring 4 is larger than the outer diameter of the lower ring 2212; the t...

Embodiment 3

[0066] The difference between this embodiment and the above-mentioned embodiment is that: Image 6 , Figure 7 As shown, the flow diverter 23 of this embodiment is a funnel-shaped structure with a large upper opening and a small lower opening.

[0067] By designing the diverter 23 as a funnel-shaped structure with a large upper opening and a smaller lower opening, it is ensured that the high-pressure fluid containing impurities is smoothly introduced into the first-stage filter screen 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com