PVC expansion sheet surface decorative paper laminating device

A lamination device and decorative paper technology, applied in lamination devices, lamination, layered products, etc., can solve the problems of easy generation of air bubbles, low efficiency, uneven glue application, etc., to achieve better lamination effect and convenient collection , Improve the effect of bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

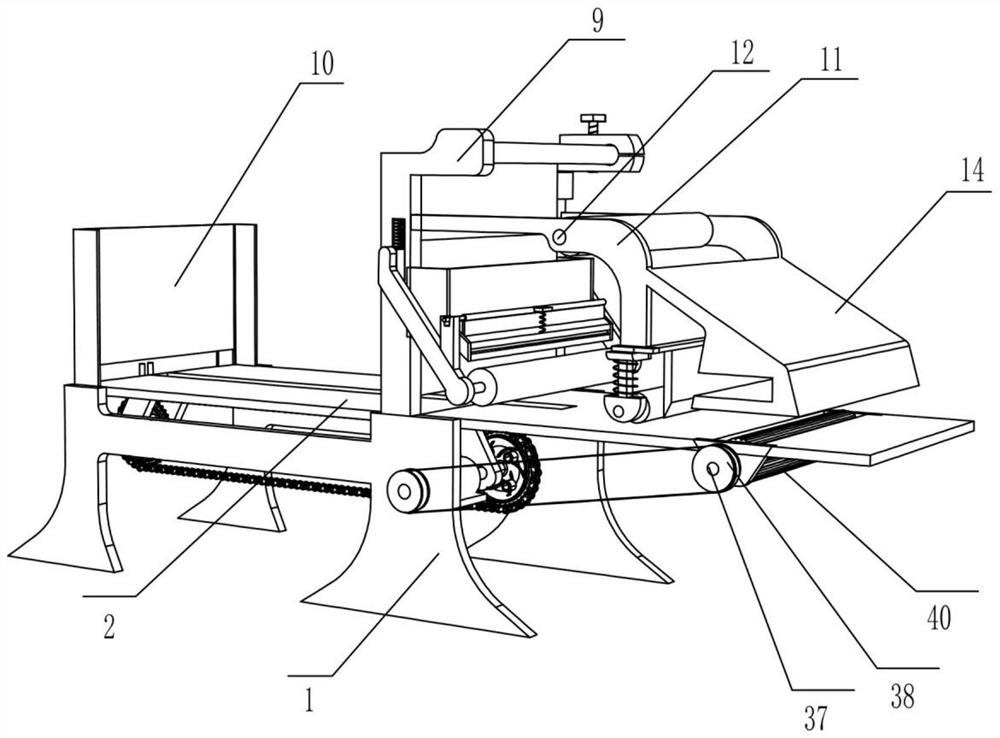

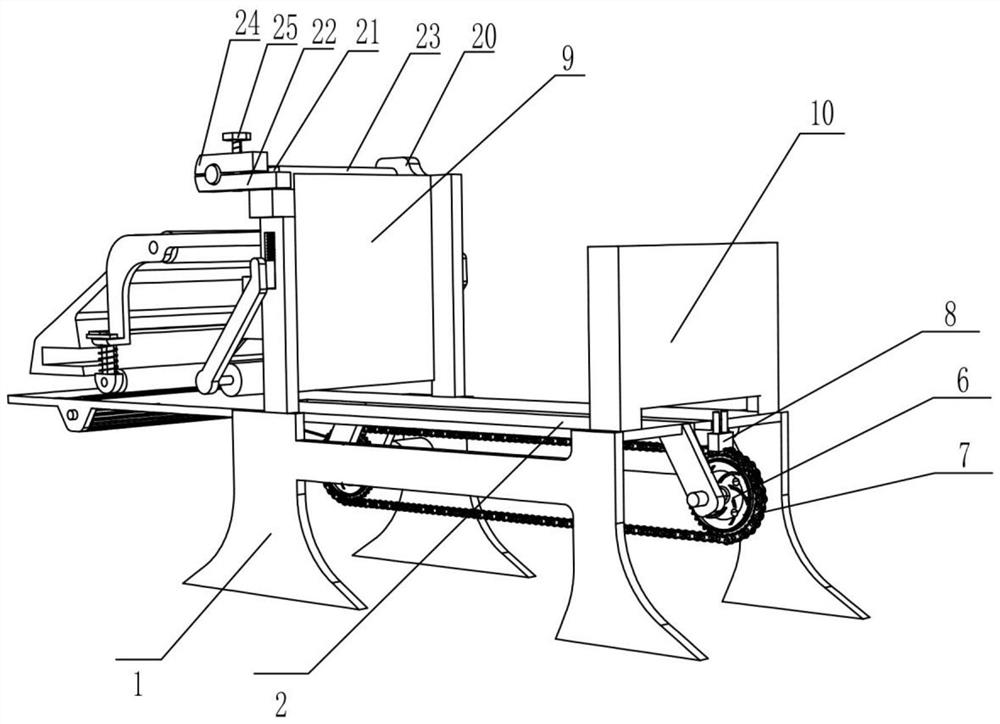

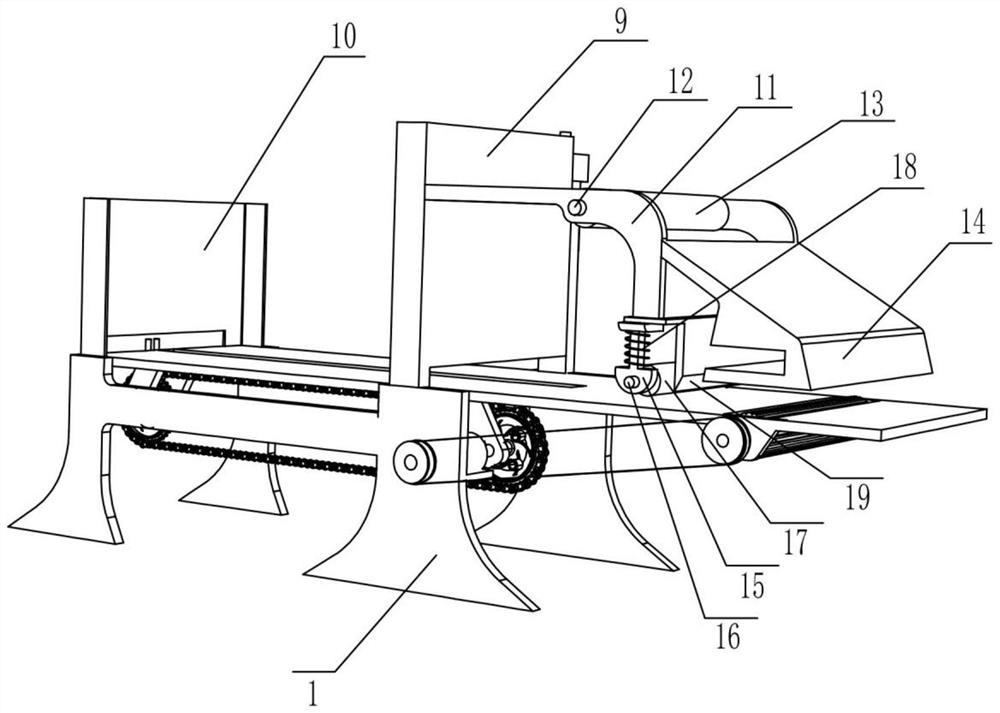

[0021] A kind of laminating device for decorative paper on the surface of Chevron board, such as Figure 1-5 As shown, it includes a base 1, a machine 2, a double-axis motor 3, a rotating shaft 4, a fixed plate 5, a gear 6, a chain 7, a push block 8, a rear limiter frame 9, a front limiter frame 10, and a support plate 11 , movable rod one 12, roller one 13, top material plate 14, telescoping rod 15, movable rod two 16, fitting wheel 17, spring one 18, cutter 19, unwinding mechanism and blanking mechanism, described can place snow The machine 2 of the Buddhist board is fixedly installed on the base 1, the biaxial motor 3 which plays a driving role is fixedly installed on one side of the base 1, and the four fixed plates 5 are divided into two groups and fixedly installed on the lower side of the machine 2 And it is arranged symmetrically, and one of the fixed plates 5 is close to the biaxial motor 3, and the three rotating shafts 4 are respectively rotatably installed on the f...

Embodiment 2

[0026] On the basis of Example 1, such as Figure 1-5As shown, the blanking mechanism that can automatically control blanking includes a sliding block 26, a lifting frame 27, a spring two 28, a push plate 29, a movable rod four 30, a paint wheel 31, a glue rack 32, a material retaining splint 33, The connecting block 34 and the spring three 35, the two sliding blocks 26 are respectively slidably installed on the two chutes of the rear material limiting frame 9 and arranged symmetrically, and the upper ends of the two lifting frames 27 are fixedly connected with the two sliding blocks 26 respectively , the upper ends of the two reset springs 28 are respectively fixedly connected to the inner sides of the rear material limiter 9, and the lower ends are respectively fixedly connected to the upper sides of the two sliding blocks 26, and the lower ends of the pushing plates 29 that play the role of pushing are fixedly installed in the rear The upper side of the lifting frame 27 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com