Modular installation method for vertical annealing furnace

A technology of vertical annealing furnace and installation method, which is applied to furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of long construction time and low efficiency, and achieve fast installation, improved reliability and precision, and fast furnace shell correction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

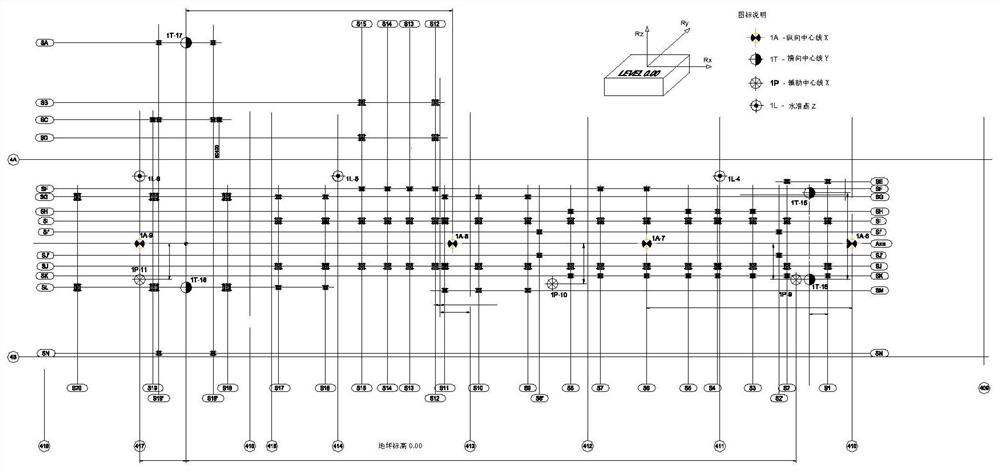

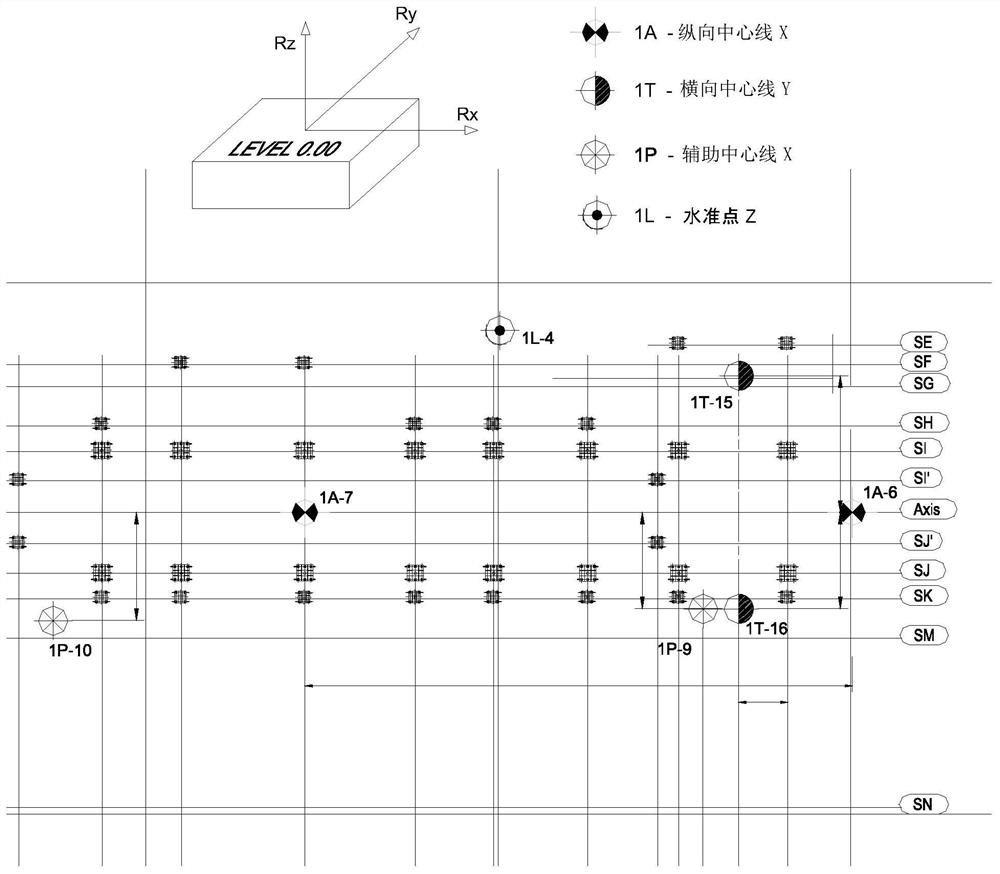

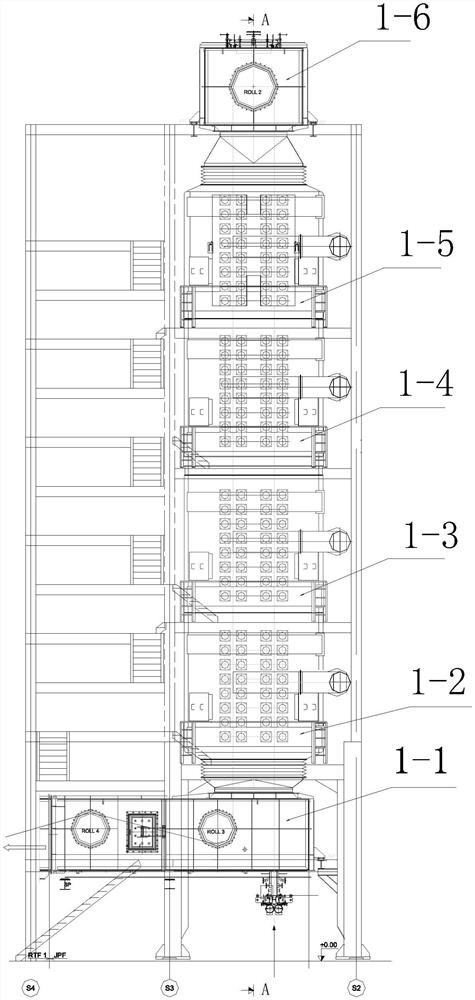

[0048] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

[0049] The patent of the present invention considers improving the installation process of the furnace shell. According to the structural type of each section of the annealing furnace, the overall installation method after the modularized pre-assembled furnace shell is selectively adopted, and the fixing and protection measures after assembly are added. Refractory material construction in the furnace, and finally installation of furnace rollers, radiant tubes and other equipment. It is characterized by the realization of "modularization" and "quick installation" of vertical annealing furnace installation, so as to achieve the purpose of rapid installation of vertical annealing furnace and shorten the installation and adjustment time of furnace equipment.

[0050] A modular installation method for a vertical annealing furnace. Firstly, modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com