Waste heat recycling RTO combustion furnace

A combustion furnace and combustion chamber technology, applied in the direction of combustion method, combustion type, combustion technology mitigation, etc., can solve the problems that the exhaust gas cannot reach the combustion temperature, is not enough to achieve the purpose of preheating, and the volume of organic waste gas is reduced, so as to improve the pre-heating Heat effect, improve heat absorption effect, reduce heat loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] The present invention will be further described in detail below in conjunction with the drawings.

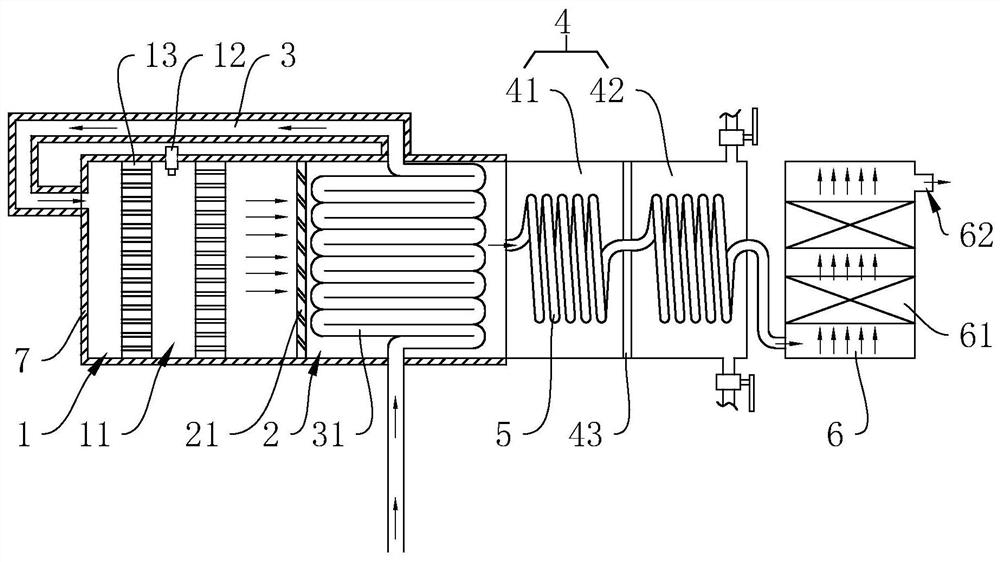

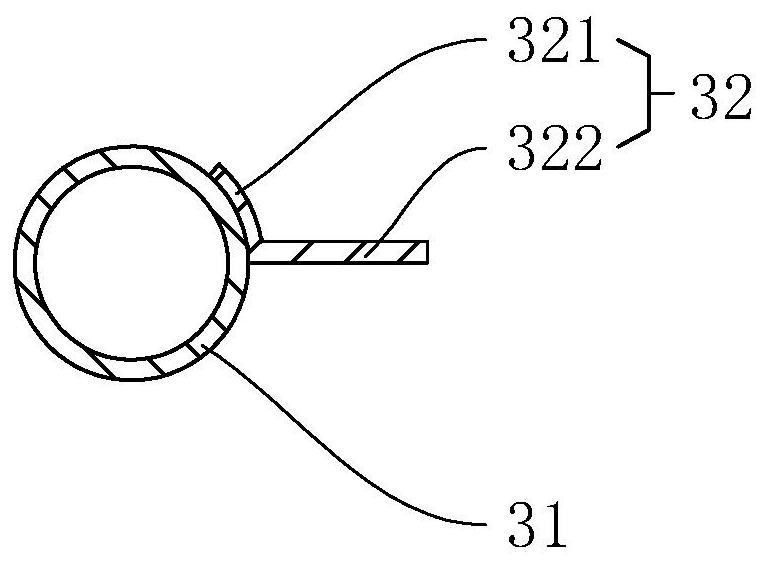

[0041] An exhaust gas combustion device for preventing the blockage of heat storage materials, such as figure 1 As shown, it includes an exhaust gas pipe 3 for transmitting organic waste gas, a preheating chamber 2 for preheating the organic waste gas in the exhaust gas pipe 3, a combustion chamber 1 for burning and purifying organic waste gas, and a combustion chamber 1 for recovering high temperature after combustion. A heat exchange chamber for the heat in the exhaust gas, and a filter chamber 6 for further adsorption and purification of the burned exhaust gas. The middle section of the exhaust gas pipe 3 passes through the preheating chamber 2, and the pipe section of the exhaust gas pipe 3 in the preheating chamber 2 is a preheating pipe 31 with good thermal conductivity.

[0042] A breathable partition 21 is provided between the preheating chamber 2 and the combustion ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com